Preparation method and preparation equipment for composite polyiron water purifying agent

A production method and technology of production equipment, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as social hidden dangers, and achieve the effects of high production efficiency, low cost and good water purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

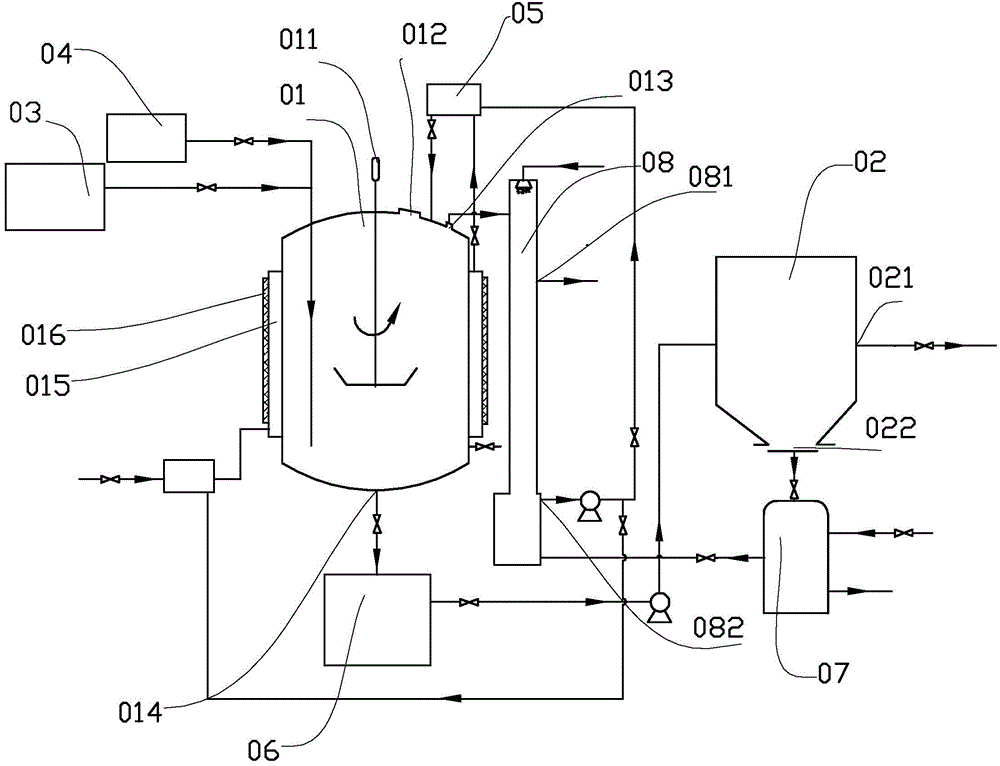

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of production method of composite polyiron water purifying agent PFAS-1, concrete steps are as follows:

[0028] a): adding waste sulfuric acid to the reactor;

[0029] b): Slowly add waste sulfuric acid quality 8% hydrogen peroxide (H 2 o 2 ), stirred for 10 minutes until the ferrous ions were completely oxidized, at this time the main component in the solution was H 2 SO 4 and Fe 2 (SO 4 ) 3 ;

[0030] c): Add hot water 2.5 times the mass of waste sulfuric acid to raise the temperature in the reactor to above 60°C, then add CaAl with 16% mass of waste sulfuric acid 2 o 4 , Stir, control the pH value to 2.5, control the reaction temperature at 70-80°C; the chemical reaction formula of the product is: Fe 2 (SO 4 ) 3 +H 2 SO 4 +CaAl 2 o 4 +2H 2 O=[Fe 2 (OH) 2 (SO 4 ) 2 ] m +[Al 2 (OH) 4 SO 4 ] n +CaSO 4 .

[0031] d): isolated product, CaSO 4 Insoluble in water, it settles at the bottom, separates the precipitate, and the ...

Embodiment 2

[0035] Embodiment 2: a kind of production method of composite polyiron water purifying agent PFAS-2, concrete steps are as follows:

[0036] a): first set the quality of the waste sulfuric acid that will be added to the reactor, add the ferrous sulfate of 20% of the waste sulfuric acid quality, then add water with 5 times the quality of ferrous sulfate, stir, and the ferrous sulfate is completely dissolved; finally set the A certain amount of waste sulfuric acid is added to the reactor;

[0037] b): Slowly add waste sulfuric acid quality 12% hydrogen peroxide (H 2 o 2 ), stirred for 15 minutes until the ferrous ions were completely oxidized, at this time the main component in the solution was H 2 SO 4 and Fe 2 (SO 4 ) 3 ;

[0038] c): Add hot water 2.5 times the mass of waste sulfuric acid to raise the temperature in the reactor to 60°C, then add CaAl with 19% mass of waste sulfuric acid 2 o 4 , Stir, control the pH value to 2.5, control the reaction temperature at 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com