A kind of polypropylene heat-resistant and weather-resistant masterbatch, preparation method and application thereof

A polypropylene and weather-resistant masterbatch technology, which is applied in the field of polymer material modification, can solve the problems of accelerated degradation of polypropylene molecular segments, poor heat and weather resistance, etc., to improve heat and weather resistance, increase production efficiency, and save energy. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

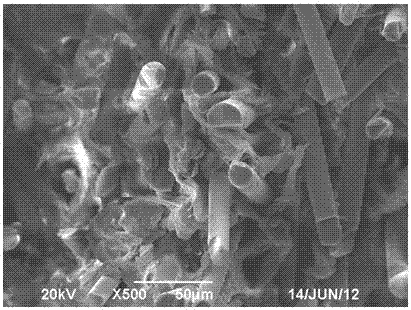

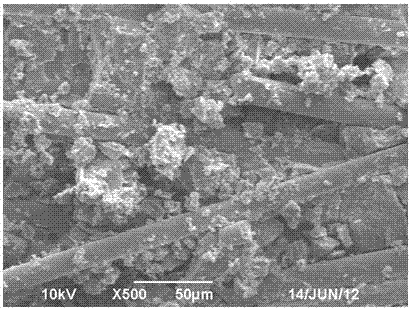

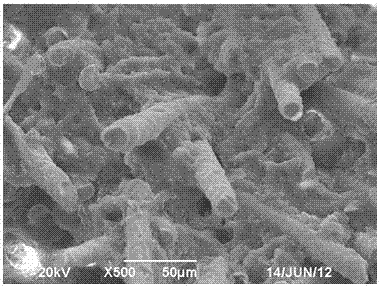

Image

Examples

Embodiment 1

[0033] Put polypropylene: 87 parts, antioxidant: 6 parts, light stabilizer: 1 part, light stability auxiliary agent: 5 parts, heat-resistant stabilizer: 1 part, processing aid 0.1 part, put them into a high-speed mixer and mix 5 minutes, then put the mixture into the twin-screw extruder and extrude. The temperature of each section of the barrel of the twin-screw extruder is set as follows: 170°C for the first zone, 175°C for the second zone, 185°C for the third zone, and 185°C for the fourth zone , 190°C in the fifth zone, 190°C in the sixth zone, and 195°C at the machine head. The extruded strips are cooled to room temperature through a circulating water tank, dried by a blower, and then entered into a pelletizer for granulation. Described polypropylene is PP S2040 of Shanghai Secco Petrochemical Co., Ltd., described antioxidant is 3 parts of antioxidant 1010 and 3 parts of antioxidant 168, and described light stabilizer is BASF's Light stabilizer 770, the light stabilizer a...

Embodiment 2

[0035] Put polypropylene: 76 parts, antioxidant: 8 parts, light stabilizer: 3 parts, light stability auxiliary agent: 10 parts, heat-resistant stabilizer: 3 parts, processing aid 0.3 parts, put them into a high-speed mixer and mix 5 minutes, then put the mixture into the twin-screw extruder and extrude. The temperature of each section of the barrel of the twin-screw extruder is set as follows: 180°C for the first zone, 185°C for the second zone, 185°C for the third zone, and 190°C for the fourth zone , 195°C in the fifth zone, 195°C in the sixth zone, and 200°C at the head. The extruded strips are cooled to room temperature through a circulating water tank, dried by a blower, and then entered into a pelletizer for granulation.

[0036] The polypropylene is PP K7926 of Shanghai Secco Petrochemical Co., Ltd., and the antioxidant is 2 parts of antioxidant 1076, 2 parts of antioxidant 618 and 4 parts of antioxidant DSTDP. Described light stabilizer is the light stabilizer 770 of ...

Embodiment 3

[0038] Put polypropylene: 65 parts, antioxidant: 10 parts, light stabilizer: 5 parts, light stability auxiliary agent: 15 parts, heat-resistant stabilizer: 5 parts, processing aid 0.5 parts, put them into a high-speed mixer and mix 3 minutes, then put the mixture into the twin-screw extruder and extrude. The temperature of each section of the barrel of the twin-screw extruder is set to: 170°C for the first zone, 195°C for the second zone, 210°C for the third zone, and 210°C for the fourth zone , Five zone 220°C, six zone 225°C, machine head 230°C. The extruded strips are cooled to room temperature through a circulating water tank, dried by a blower, and then entered into a pelletizer for granulation. .

[0039] The polypropylene is Yanshan Petrochemical PP K7726H, the antioxidant is 3 parts of antioxidant 1076, 3 parts of antioxidant 618 and 4 parts of antioxidant DLTDP, and the light stabilizer is 3 parts of BASF's light stabilizer 770 and 2 parts of BASF's light stabilizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com