Silicone rubber sealing gasket for fire-proof seam and preparation method of silicone rubber sealing gasket

A silicone rubber and gasket technology, which is used in the field of silicone rubber gaskets for refractory joints and their preparation, can solve problems such as embrittlement, joint falling off, and easy deformation.

Inactive Publication Date: 2014-10-15

穆晓凤

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, the silicone rubber gasket material used for refractory joints in the prior art is easily deformed and brittle in a long-term high-temperature environment, and it is easy to fall off from the joint under the action of external stress

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

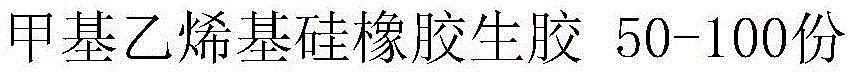

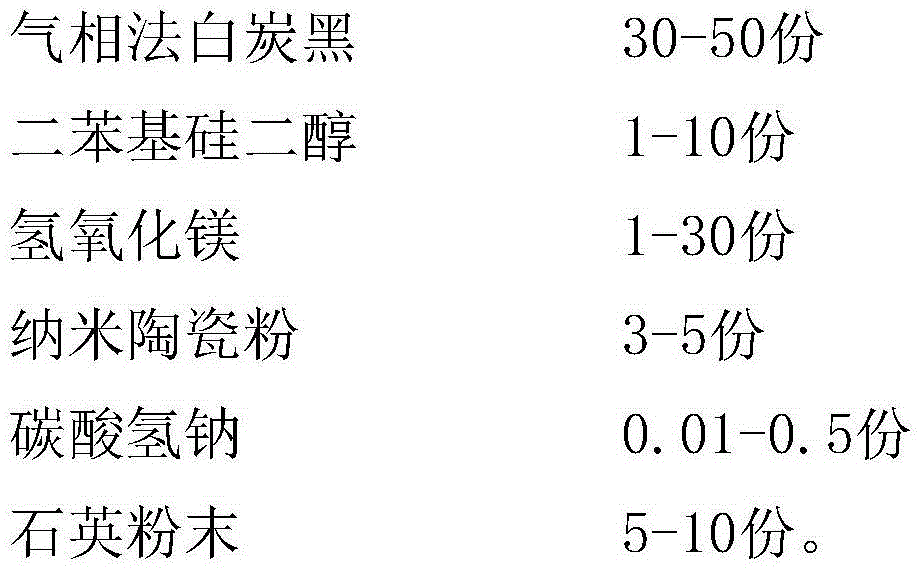

[0012] A silicone rubber gasket for fire-resistant joints, consisting of the following components by weight,

[0013]

[0014] Preparation: mix methyl vinyl silicone rubber raw rubber, fumed white carbon black and diphenylsilanediol in a kneader, control the temperature at 150 degrees Celsius, and add magnesium hydroxide, nano Ceramic powder, sodium bicarbonate and quartz powder are plasticized on a twin-roller machine to make rubber.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a silicone rubber sealing gasket for a fire-proof seam, and relates to the technical field of rubber products. The method comprises the following steps: mixing the methyl vinyl silicone raw rubber, white carbon black and diphenyl silanediol in a kneading machine, controlling the temperature at 150 DEG C, performing heat treatment for 4 hours, adding magnesium hydrate, nano ceramic powder, sodium bicarbonate and quartz powder, and plasticizing in a double-roller machine so as to be prepared into a sizing material. The product is not deformed and tendered in long time under high temperature of flame, is not easy to drop from the seam under the action of external stress, and can prevent smog, flame and hot gas from penetrating through the seam; the fire-proof mixed silicone rubber can be prepared by adding magnesium hydrate and platinum complex material in a formula, a hard ceramic protective layer can be formed on the surface of the silicone rubber when the silicone rubber is in contact with the flame, so that the silicone rubber cannot drop from the seam.

Description

technical field [0001] The invention relates to the technical field of rubber products, in particular to a silicone rubber gasket for fire-resistant joints and a preparation method thereof. Background technique [0002] Silicone rubber (English name Silicone rubber) can be divided into thermal vulcanization type (high temperature vulcanization silicone HTV) and room temperature vulcanization type (RTV). Among them, the room temperature vulcanization type is divided into polycondensation reaction type and addition reaction type. High temperature silicone rubber is mainly used to manufacture various silicone rubber products, while room temperature silicone rubber is mainly used as adhesive, potting material or mold. The thermal vulcanization type is used in the largest amount, and the thermal vulcanization type is divided into methyl silicone rubber, methyl vinyl silicone rubber, methyl vinyl phenyl silicone rubber, and other silicone rubber and fluorosilicone rubber. Among m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L83/07C08K13/02C08K3/36C08K3/22C08K3/26C08K5/5419C08K3/00

Inventor 穆晓凤

Owner 穆晓凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com