Epoxy resin adhesive

A technology of epoxy resin and adhesive, which is applied in the direction of epoxy resin glue, novolac epoxy resin adhesive, adhesive, etc., can solve problems such as difficult coordination, and achieve extended pot life, good insulation performance, and increased mechanical strength. Effect of Strength and Sealing Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

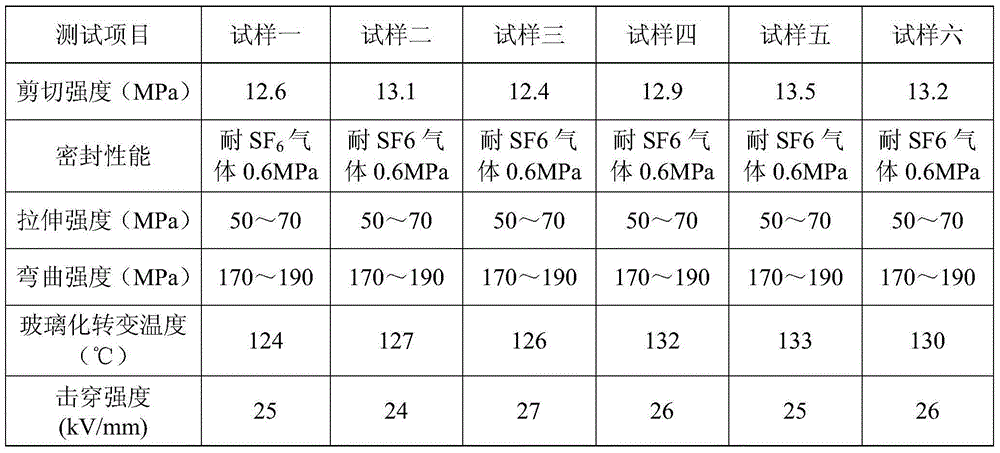

Examples

Embodiment 1

[0025] An epoxy resin adhesive comprises the following components in parts by weight:

[0026] 40 parts bisphenol A epoxy resin E-39;

[0027] 15 parts of anhydride curing agent HY1235, 15 parts of anhydride curing agent EK860;

[0028] 10 parts toughening agent 820;

[0029] 10 parts thinner 0210;

[0030] 5 parts of reinforcing material nano-scale silicon dioxide;

[0031] 1 part Accelerator DMP-30 and 1 part Accelerator S-440.

Embodiment 2

[0033] An epoxy resin adhesive comprises the following components in parts by weight:

[0034] 30 parts bisphenol A epoxy resin E-44;

[0035] 20 parts of anhydride curing agent HY1235;

[0036] 20 parts of toughening agent 820, 5 parts of toughening agent QS-N;

[0037] 20 parts thinner XY207;

[0038] 8 parts of reinforcing material nano-scale silicon dioxide;

[0039] 0.1 part Accelerator S-440.

Embodiment 3

[0041] An epoxy resin adhesive comprises the following components in parts by weight:

[0042] 20 parts of phenolic resin F-44;

[0043] 20 parts of anhydride curing agent EK860;

[0044] 15 parts toughening agent QS-N;

[0045] 15 parts thinner XY217;

[0046] 10 parts superfine silicon dioxide as reinforcing material;

[0047] 0.5 parts of accelerator DMP-30, 0.3 parts of 2-methylimidazole and 0.9 parts of accelerator 2-ethyl-4-methylimidazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com