Circulating fluidized bedboiler cyclone separator provided with entirely inclined center cylinder

A cyclone separator and circulating fluidized bed technology, which is applied to fluidized bed combustion equipment, fuel burned in a molten state, lighting and heating equipment, etc., can solve the problem of low separation efficiency of the separator, large consumption of limestone, and the High separation efficiency, low difficulty in manufacturing and on-site installation, and reduced median particle size of fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

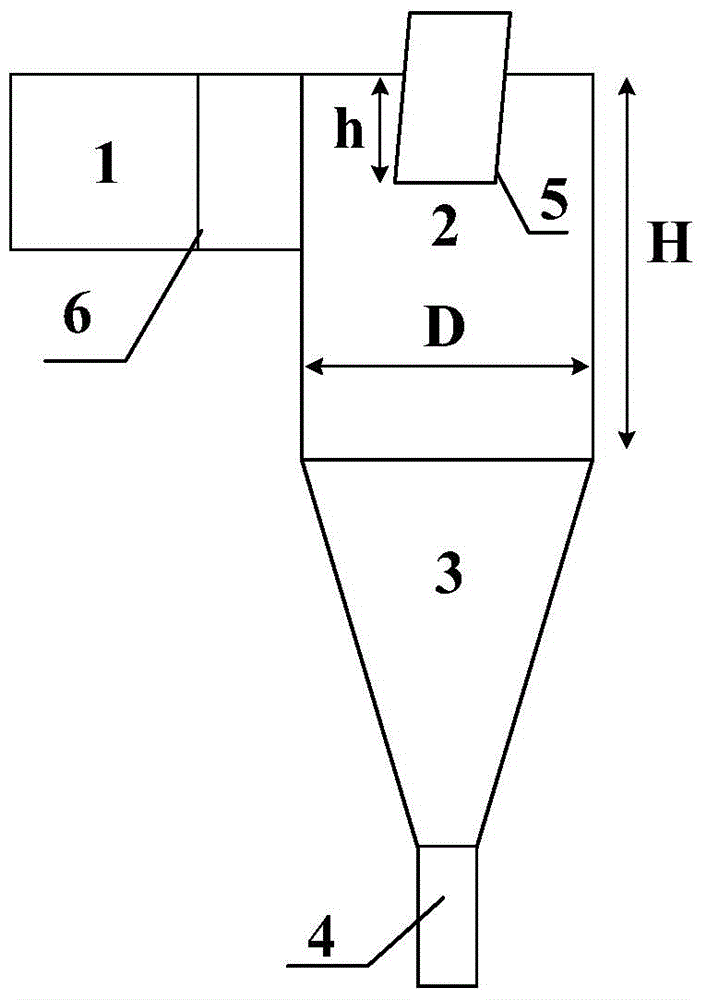

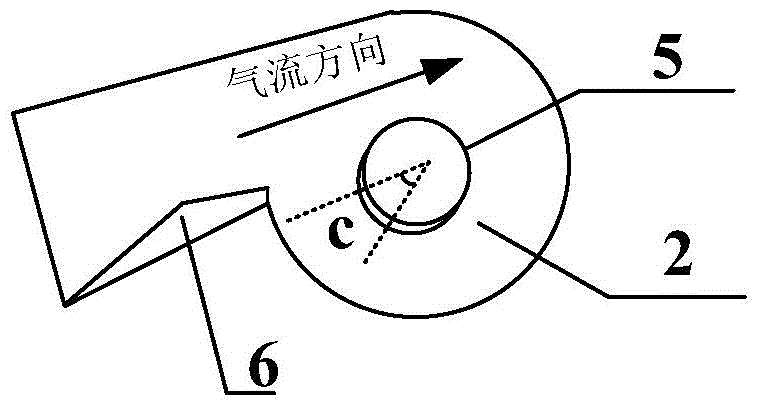

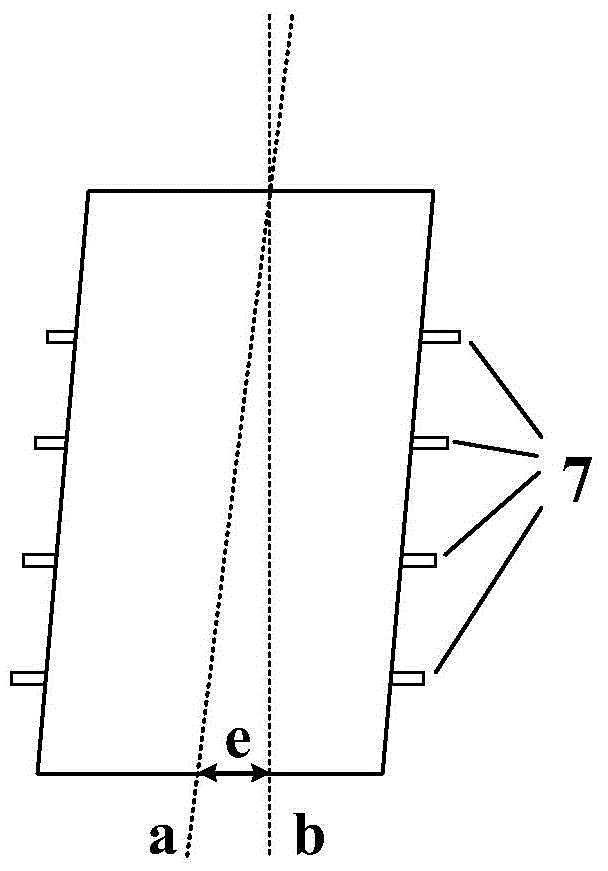

[0052] A new 240t / h circulating fluidized bed boiler, see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, the central cylinder of the two cyclone separators of the boiler adopts the overall inclined method, the outlet area of the flue 1 of the tapered inlet of the cyclone separator is 60% of the inlet area, and the flue gas discharged from the furnace can reach 26m / s after being accelerated, and the tapered The inlet flue 1 is equipped with a flue gas equalizing boss 6, and the thickness of the protruding part of the flue gas equalizing boss 6 is 800mm. The distance difference e between the cylinder geometric center a of the central cylinder 5 and the vertical center b of the upper surface of the overall inclined central cylinder 5 is 150mm, and the angle c between the overall inclined central cylinder 5 and the airflow direction is 60°, and the overall inclined central cylinder 5. The depth h of inserting the separator is 20% of the height H of the separator ...

Embodiment 2

[0054] For a 480t / h circulating fluidized bed boiler in service, the central cylinder of the two cyclone separators of the boiler adopts a conventional design. During operation, the load capacity is insufficient, the boiler output is generally only 60% to 75%, the ash concentration in the furnace is low, the pressure difference in the suspension section is only 500Pa, and the bed temperature cannot be effectively adjusted. 2 Emission concentration 600mg / m 3 , NO X Emission concentration 400mg / m 3 , the molar ratio of calcium to sulfur in limestone is as high as 5-6, the efficiency of the separator is low, and the effective circulation of materials cannot be realized. The measured median particle size of boiler fly ash is 110μm, and the separator resistance is 600Pa.

[0055] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the central cylinder of the boiler cyclone separator is replaced and transformed by adopting the overall tilting method of the cent...

Embodiment 3

[0057] A new 720t / h circulating fluidized bed boiler, see figure 1 , figure 2 , image 3 , Figure 4 and Image 6 , the center tubes of the three cyclone separators of the boiler adopt an overall tilting method, and the top fixing method of the overall tilting center tube 5 is a free-hanging fixing method, which is freely matched with the separator tube body 2 and can slide relative to each other in a hot state. Expansion dead point,; the outlet area of the tapered inlet flue 1 of the cyclone separator is 55% of the inlet area, and the flue gas discharged from the furnace can reach 24m / s after acceleration, and the tapered inlet flue 1 is equipped with flue gas equalization Boss 6, from Image 6 The thicknesses of the protruding parts of the flue gas equalizing boss 6 of the three separators from top to bottom are 600mm, 800mm and 600mm respectively; in order to improve the separation efficiency, the geometric center a of the central cylinder 5 of the three separators i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com