Solid-state capacitance negative carbon foil and manufacture method thereof

A technology of solid capacitor and negative electrode, which is applied in the direction of fixed capacitor electrodes, fixed capacitors, parts of fixed capacitors, etc., which can solve the problems of graphite falling off, affecting the conductivity and capacitance ratio of capacitors, and affecting the service life of capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

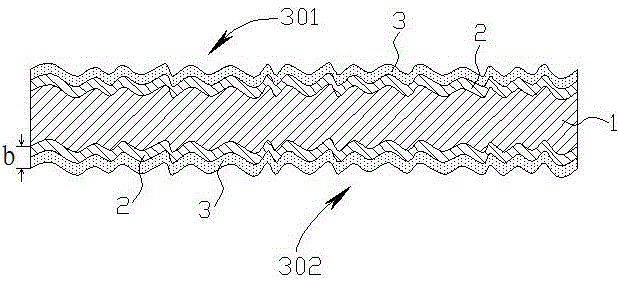

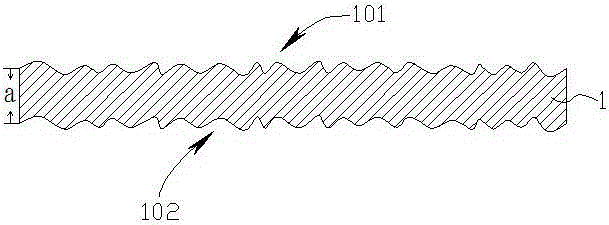

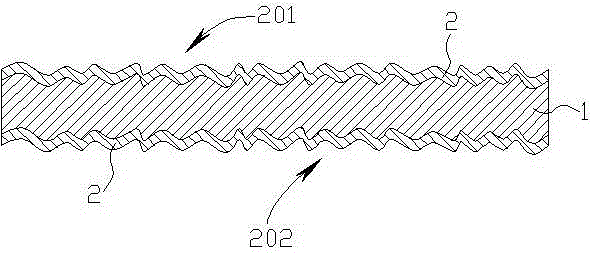

[0020] see figure 1 - image 3 , a solid capacitor negative electrode carbon foil according to the present invention, comprising a corroded aluminum foil layer 1, the corroded aluminum foil layer 1 has rough upper and lower surfaces 101, 102, and the rough upper and lower surfaces 101, 102 of the corroded aluminum foil layer 1 are passed through a magnetic The upper and lower metal transition layers 2 with strong affinity with aluminum and graphite are coated respectively by means of magnetron sputtering, and the outer surfaces of the upper and lower metal transition layers 2 are respectively coated with upper and lower graphite by means of magnetron sputtering layer 3, the upper and lower metal transition layers 2 and the upper and lower graphite layers 3 respectively have rough upper and lower transition layer surfaces 201, 202 and Rough upper and lower graphite layer surfaces 301,302. The specific meaning of the upper and lower metal transition layers having strong affini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com