Separable spiral pipe

A spiral tube and separate technology, which is applied in entertainment, stage equipment, and equipment used in theaters and circuses, etc., can solve the problems of easy plastic deformation, high cost, and damage to the steel belt 5, and achieve simple motion principle, The effect of simple connection method and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

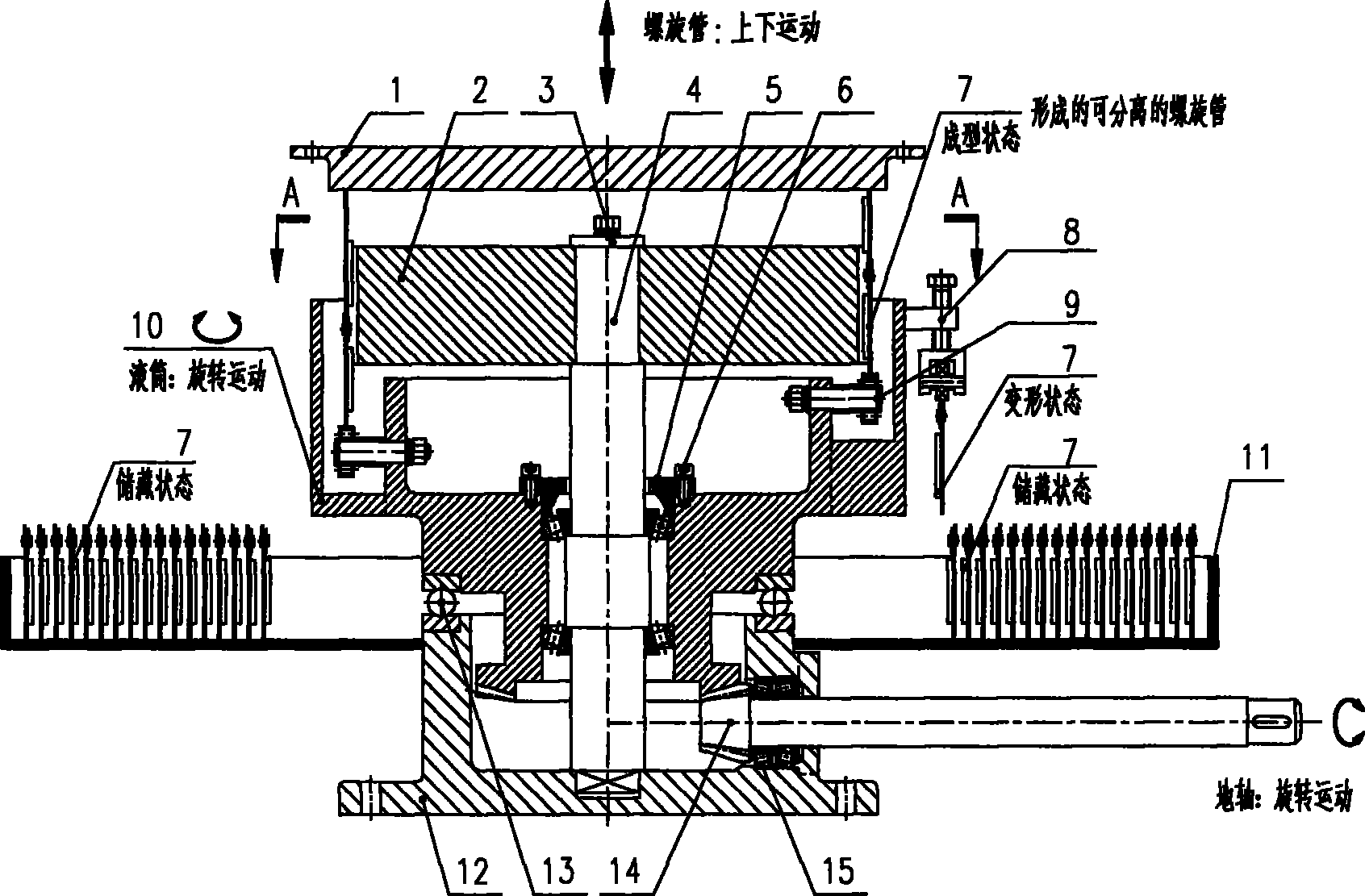

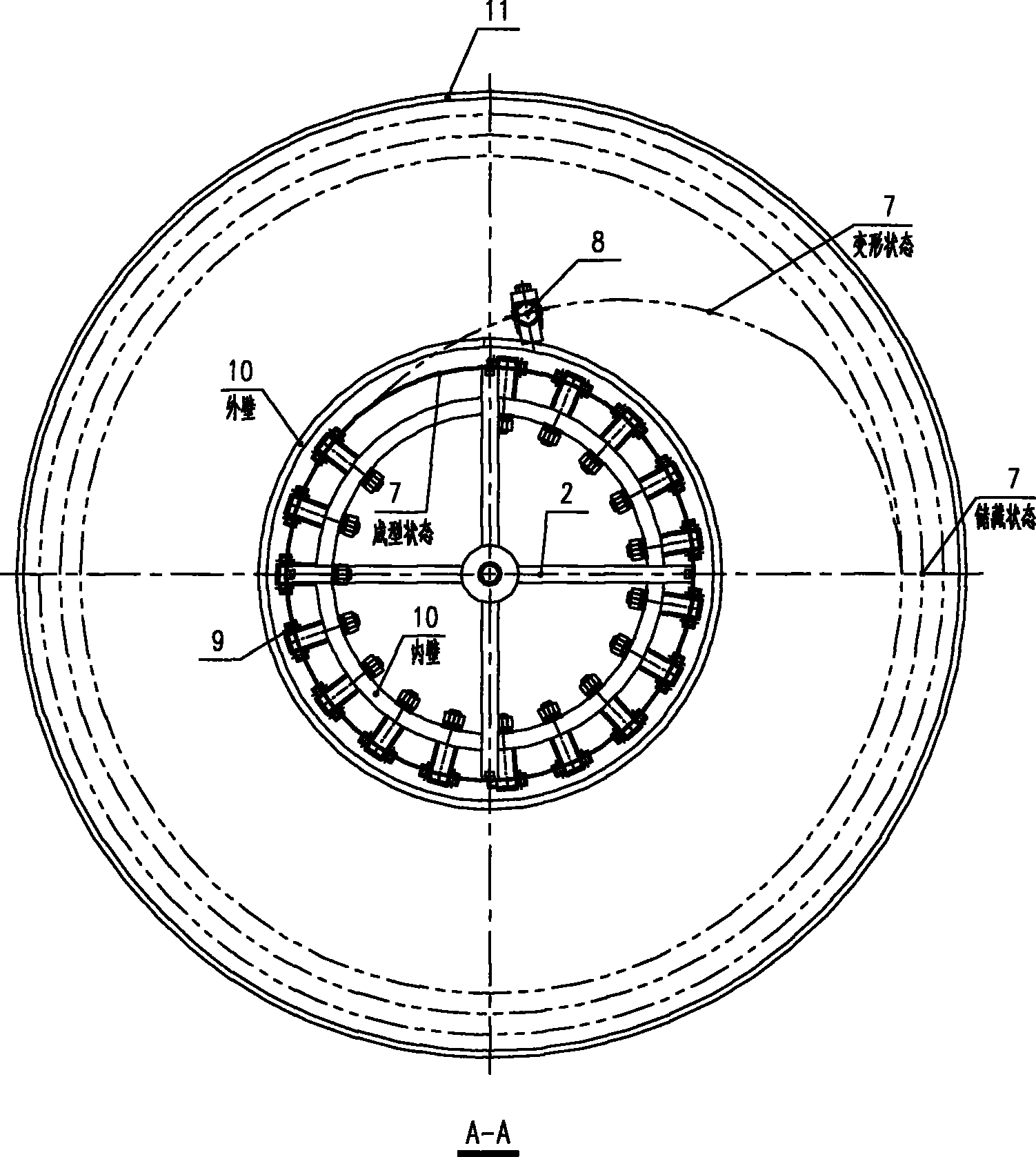

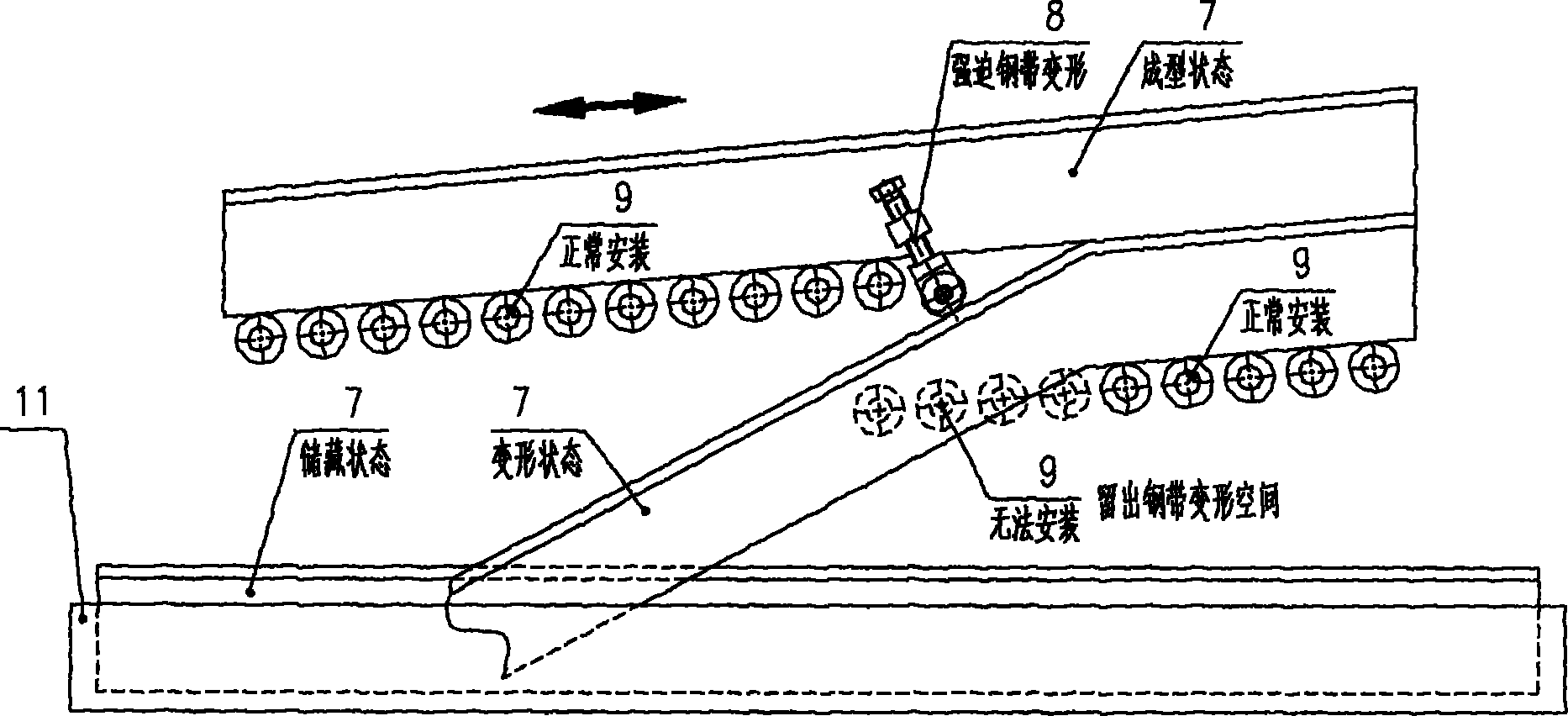

[0026] see Figure 1 to Figure 6Shown: a vertical lifting device for a separable spiral tube, which includes: the lower gear box 12 is connected with the lower installation base 20 by bolts, and the lower installation base 20 is fixed with the foundation pit through embedded parts; it can be forward and reverse The driven ground shaft (with pinion) 14 is fixed on the lower gearbox 12 through the thrust bearing 2 15; the forward and reverse roller 10 is loaded on the lower gearbox 12 through the plane bearing 13; the fixed cross guide shoe 2 passes through the central shaft 4. The rectangular cross-section at the lower end is fixed in the rectangular groove in the middle of the lower gear box 12 and cannot rotate. The thrust bearing 16 and the central pressure plate 5 installed on the drum 10 make the central shaft 4 only fixed at the central shaft position but cannot Move up and down to jointly ensure the stability of the fixed cross guide shoe 2 itself and the coaxiality of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com