Hub pressure sensor hole drilling device

A sensor hole and drilling device technology, applied in boring/drilling, positioning devices, feeding devices, etc., can solve the problems of pressure sensor holes with many steps, repeated positioning production efficiency, etc., to increase speed and reduce processing. Difficulty, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

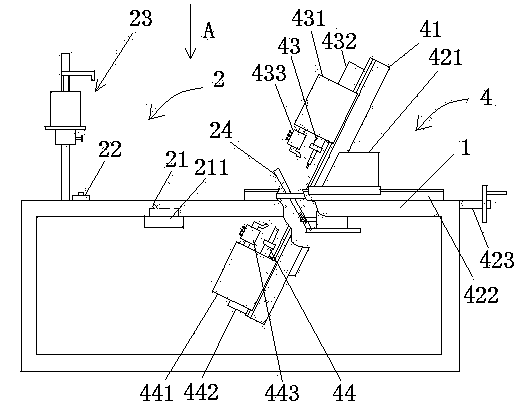

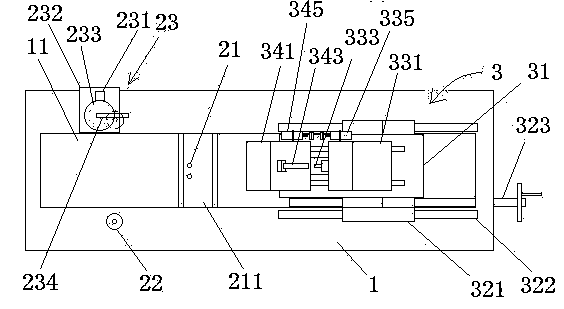

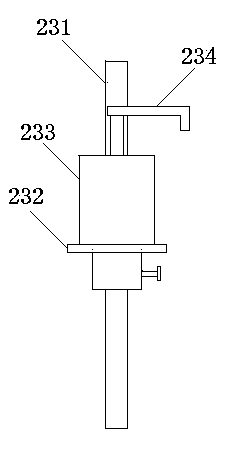

[0022] Such as figure 1 or figure 2 The hub pressure sensor hole drilling device shown includes a workbench 1, a hub fixing device 2 connected to the workbench 1, and a sensor hole drilling device 3; the workbench 1 is provided with a middle hollow 11; The hub fixing device 2 includes a valve slot positioning device 21, a limiting column 22, an axial fixing device 23 and a radial fixing device 24. The limiting column 22 is symmetrically arranged on the workbench 1 on both sides of the middle hollow 11, and the axis The fixing device 23 is located on one side of one of the limiting posts 22, and the drill bit of the sensor hole drilling device 3, the valve groove positioning device 21 and the radial fixing device 24 are respectively arranged on the vertical plane where the central axis of the limiting post 22 is located and Respectively towards the limit column 22; the radial fixing device 24 includes a fixing seat 241, and the fixing seat 241 is fixedly connected to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com