Chenille composite yarn capable of generating static electricity and achieving efficient air filtration and preparation method thereof

A technology of high-efficiency air filtration and composite yarn, which is applied in the direction of yarn, textiles and papermaking, etc., can solve the problem of high filtration efficiency, achieve good maintainability, enrich life needs, and good static electricity generation and accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

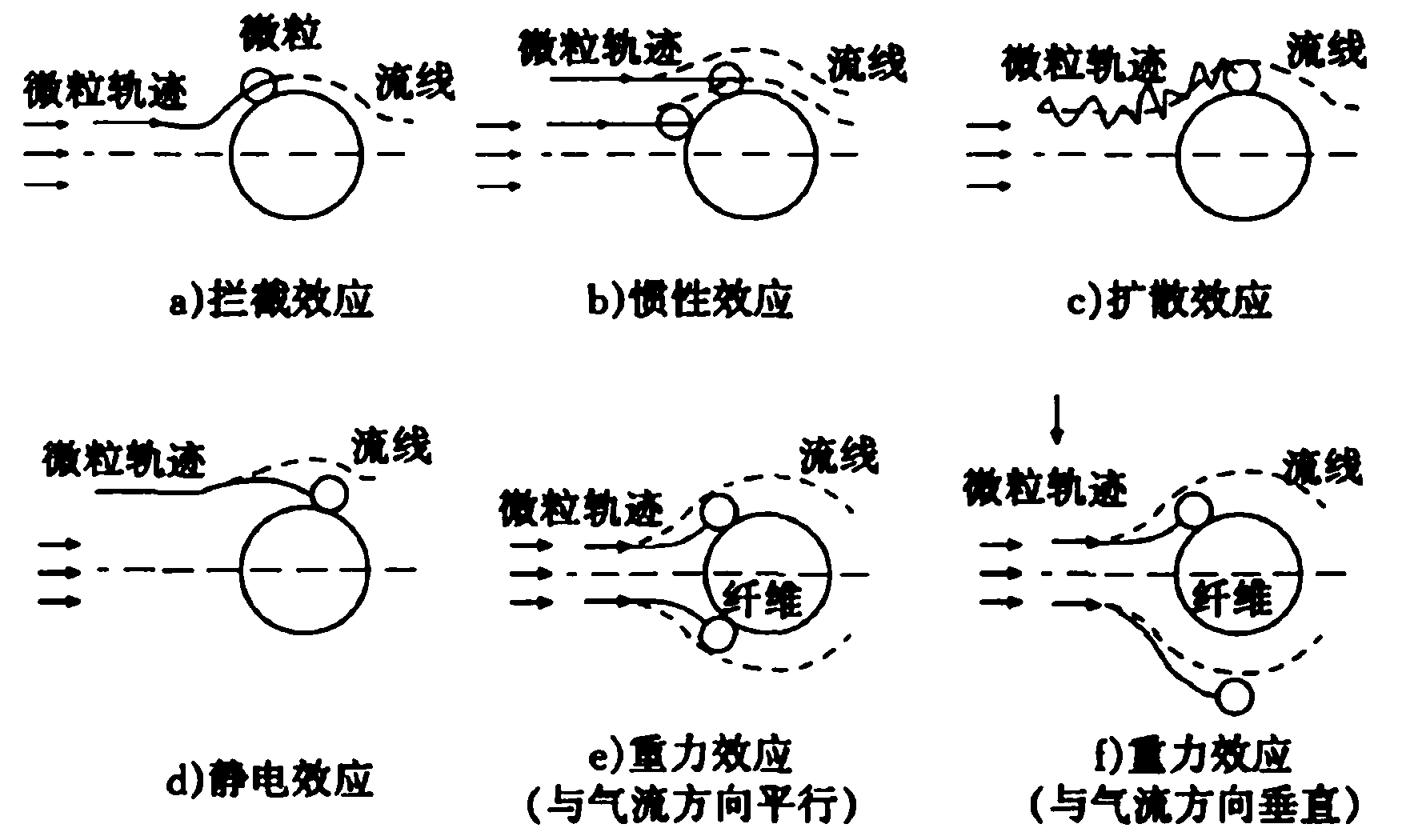

Problems solved by technology

Method used

Image

Examples

Embodiment 1

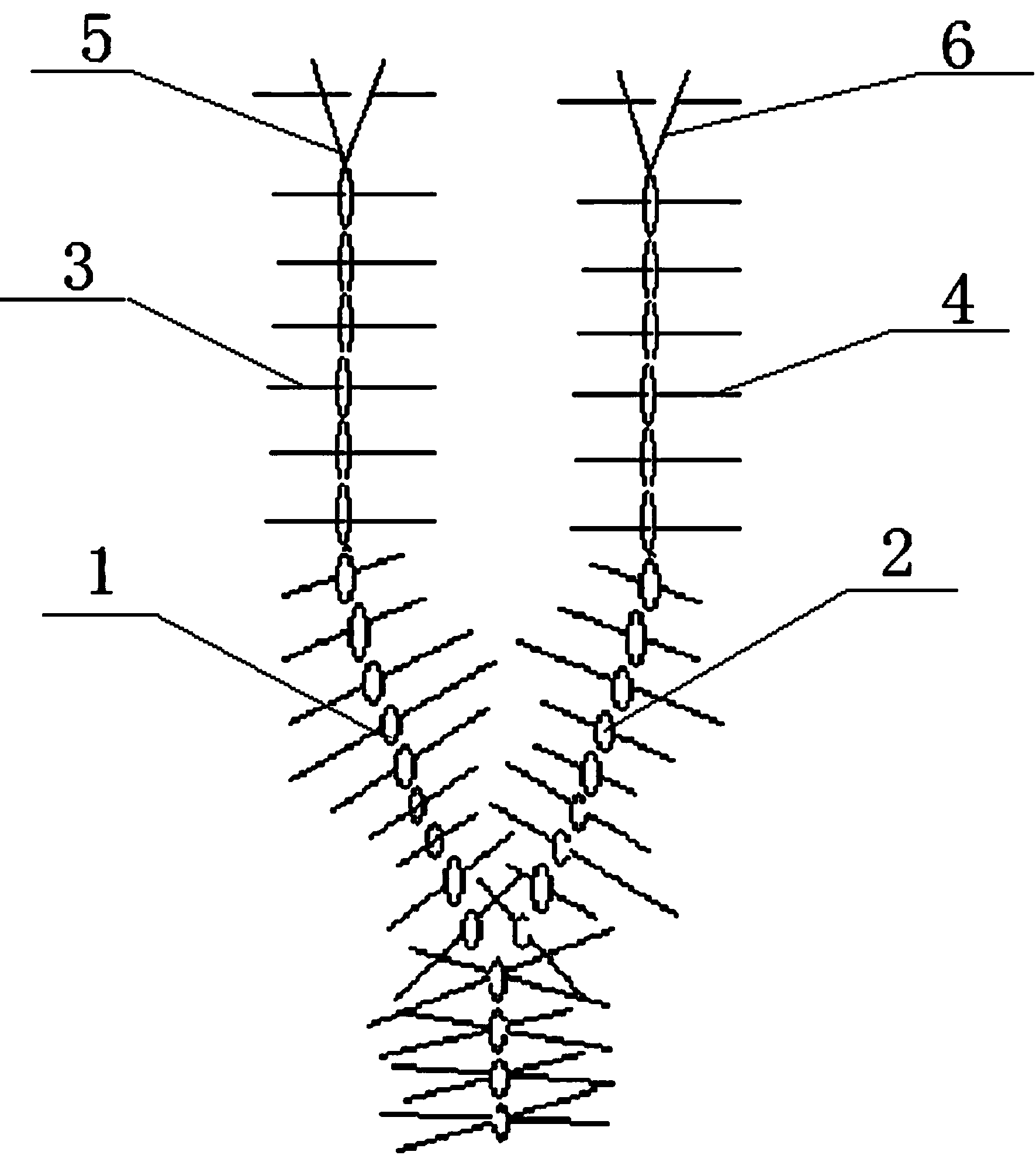

[0015] like figure 2 As shown, the chenille composite yarn used for electrostatic high-efficiency air filtration in this embodiment includes superfine fiber chenille single yarn I1 and superfine fiber chenille single yarn II2; the superfine fiber chenille single yarn Feather yarn I3 of yarn I is nylon, and feather yarn II4 of superfine fiber chenille single yarn II is polyester.

[0016] The preparation method of the chenille composite yarn for electrostatic high-efficiency air filtration in this embodiment comprises the following steps: (1) cutting the feather yarn I of the superfine fiber chenille single yarn I into tow through the chenille machine, and The tow is sandwiched into two core wires I and twisted to form a superfine fiber chenille single yarn I, and the single yarn twist of the core wire I5 is 980 twists / 5 cm; (2) the superfine fiber chenille single yarn Feather yarn II of yarn II is cut into tow by chenille machine, and the tow is clamped into two core wires...

Embodiment 2

[0018] This embodiment starts from the chenille composite yarn for electrostatic high-efficiency air filtration, including superfine fiber chenille single yarn I and superfine fiber chenille single yarn II; the ultrafine fiber chenille single yarn I Feather yarn Ⅰ is nylon, and feather yarn Ⅱ of superfine fiber chenille single yarn Ⅱ is acrylic fiber.

[0019] The preparation method of the chenille composite yarn for electrostatic high-efficiency air filtration in this embodiment comprises the following steps: (1) cutting the feather yarn I of the superfine fiber chenille single yarn I into tow through the chenille machine, and The tow is sandwiched into two core wires I and twisted to form a superfine fiber chenille single yarn I, and the single yarn twist of the core wire I is 660 twists / 5 cm; (2) the superfine fiber chenille single yarn Feather yarn II of yarn II is cut into tow by chenille machine, and the tow is clamped into two core wires II and twisted to form superfine...

Embodiment 3

[0021] This embodiment starts from the chenille composite yarn for electrostatic high-efficiency air filtration, including superfine fiber chenille single yarn I and superfine fiber chenille single yarn II; the ultrafine fiber chenille single yarn I Feather yarn I is wool, and feather yarn II of superfine fiber chenille single yarn II is polytetrafluoroethylene.

[0022] The preparation method of the chenille composite yarn for electrostatic high-efficiency air filtration in this embodiment comprises the following steps: (1) cutting the feather yarn I of the superfine fiber chenille single yarn I into tow through the chenille machine, and The tow is sandwiched into two core wires I and twisted to form a superfine fiber chenille single yarn I, and the single yarn twist of the core wire I is 780 twists / 5 cm; (2) the superfine fiber chenille single yarn Feather yarn II of yarn II is cut into tow by chenille machine, and the tow is clamped into two strands of core wire II and twis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com