External-framework built-in composite insulation board and cast-in-situ concrete integrated wall structure and manufacturing method thereof

A technology of composite thermal insulation and wall structure, applied in thermal insulation, building structure, walls, etc., can solve the problems of high construction cost, limited stress of polystyrene board, hidden fire hazards, etc. degree, the effect of increasing structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

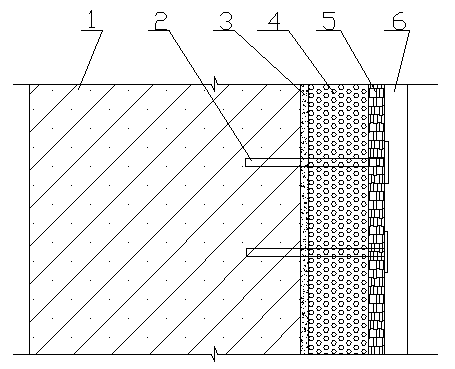

[0025] As shown in the figure, a cast-in-place concrete integrated wall structure with a built-in composite thermal insulation board in the external mold includes a cast-in-place concrete base wall 1 and a composite thermal insulation board. It is the interface layer 3, and the outer side is the reinforcement layer 5. The composite insulation board is provided with a connector 2 that runs through the reinforcement layer 5, the insulation board matrix 4, and the interface layer 3. The connector 2 protrudes from the interface layer and extends into the cast-in-place concrete base Wall 1, the insulation board composed of reinforcement layer 5, insulation board matrix 4, and interface layer 3 is firmly connected with cast-in-place concrete base wall 1; outside the composite insulation board is a plaster layer 6 thicker than 1 cm, The thickness of the thick plastering layer 6 is preferably 1.5-2 centimeters. The connector 2 is a croissant anchor bolt or a concrete product. The ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com