An air source heat pump system that recycles waste heat from compressors

An air source heat pump and compressor technology, which is applied to machines using waste heat, heat pumps, and machine operation modes, etc., can solve the problems of poor heating performance of heat pump systems, restricting the development of air source heat pumps, and reducing heating capacity. The effect of improving heating efficiency, improving efficiency and stability, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

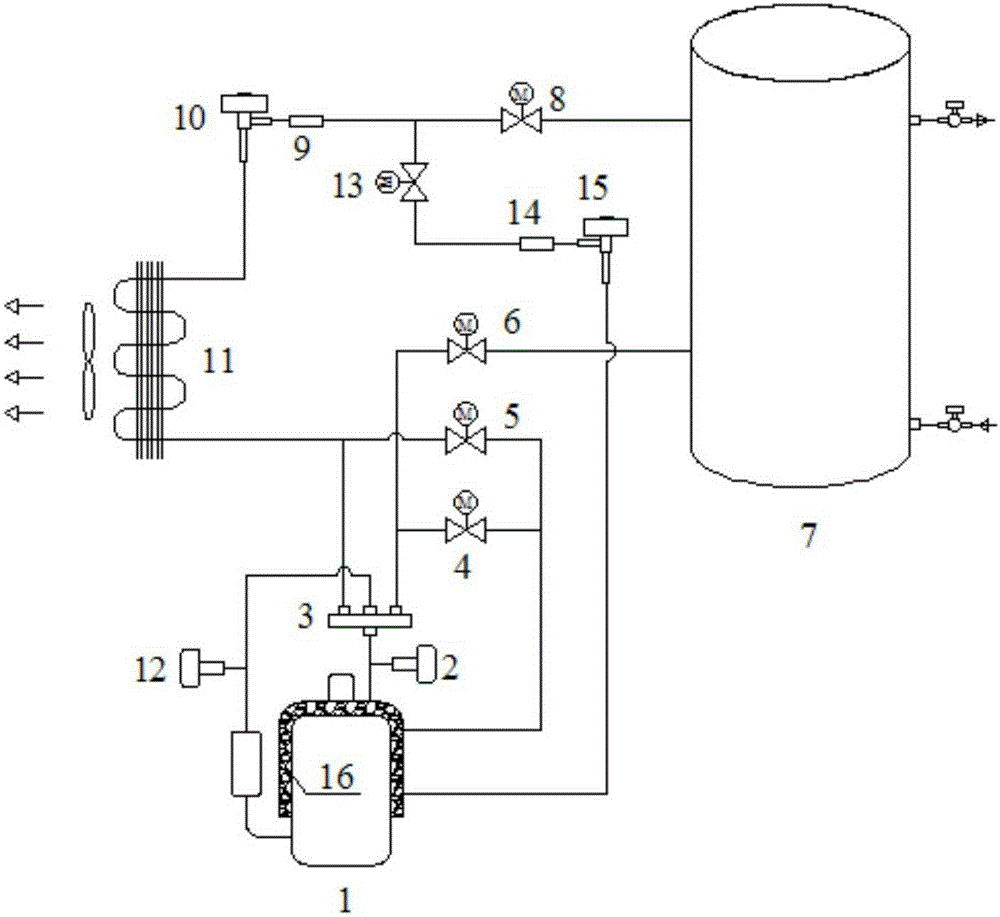

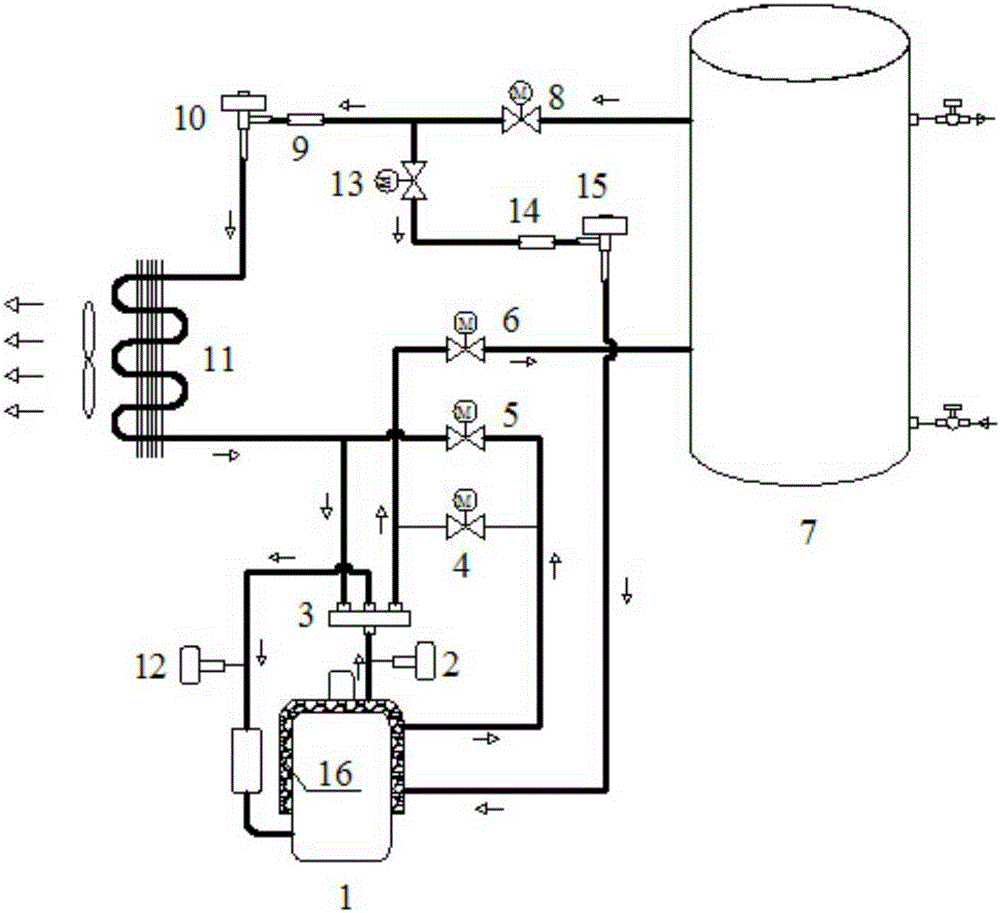

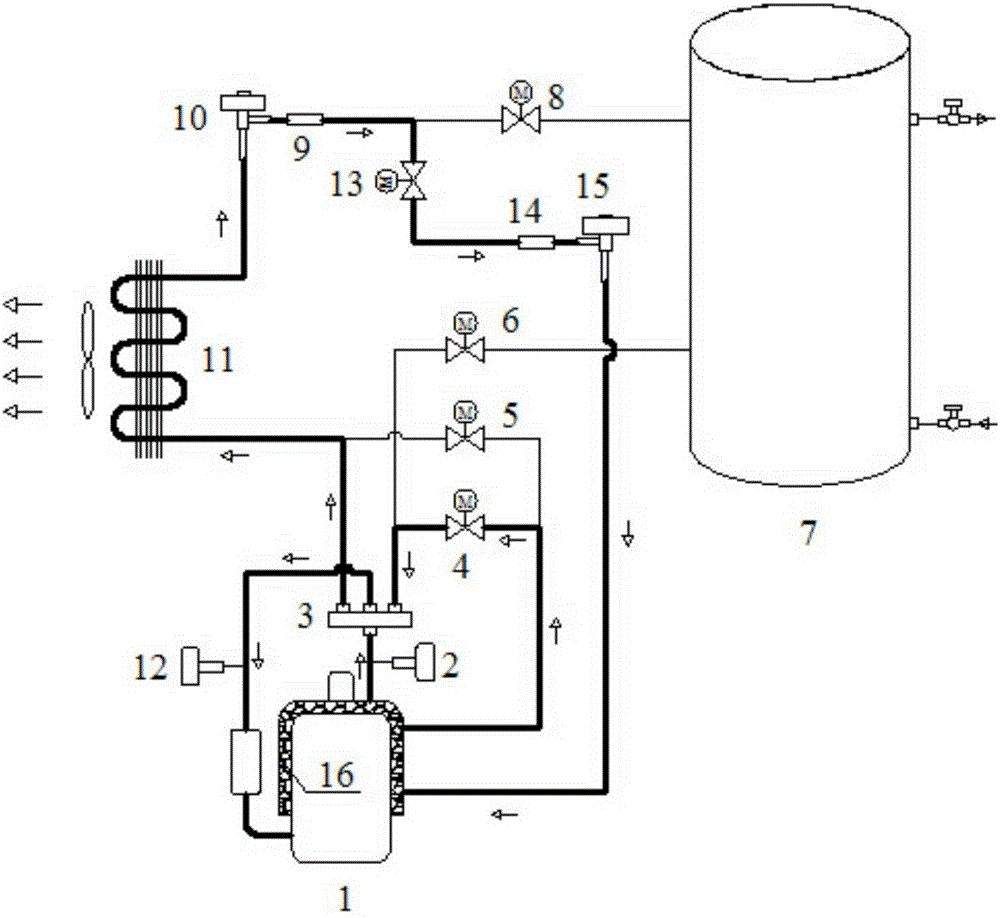

[0018] see figure 1 , the present invention includes a compressor 1, a water tank 7, and an outdoor heat exchanger 11 with a refrigeration coil wound on the outer wall; and the refrigeration coil is wrapped by a heat storage medium 16; 3. Connect to the inlet of the water tank 7 through the third electromagnetic valve 6. A high-pressure controller 2 is installed on the pipeline between the outlet of the compressor 1 and the four-way valve 3. The outlet of the water tank 7 is divided into two pipelines, one through the first The electronic expansion valve 10 and the outdoor heat exchanger 11 are connected to the four-way valve 3; the other pipeline is connected to one end of the refrigeration coil through the fifth solenoid valve 13 and the second electronic expansion valve 15, and the other end of the refrigeration coil is set The pipeline with the second so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com