High-quality, high-efficiency double-molding machine side-by-side closed-loop automatic block production line

A double forming machine and forming machine technology, which is applied in ceramic forming machines, ceramic forming workshops, stacking of objects, etc., to achieve the effect of reducing equipment investment, reducing floor space, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

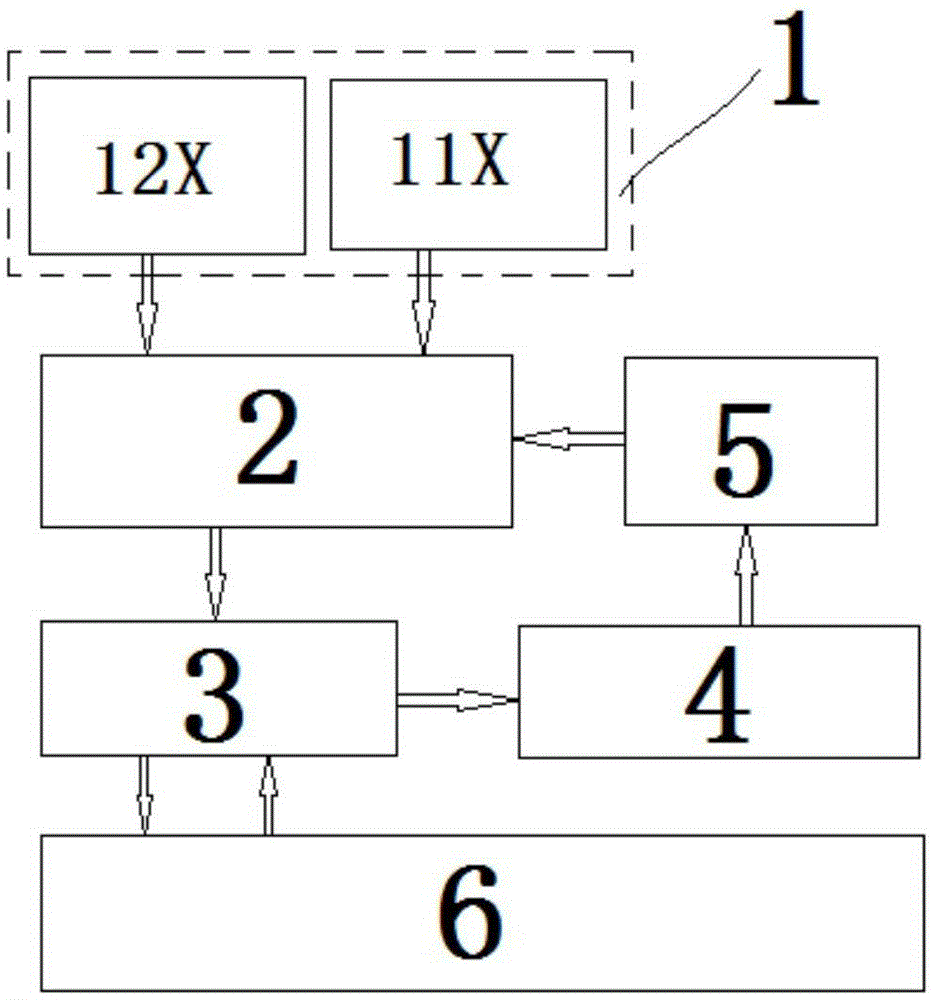

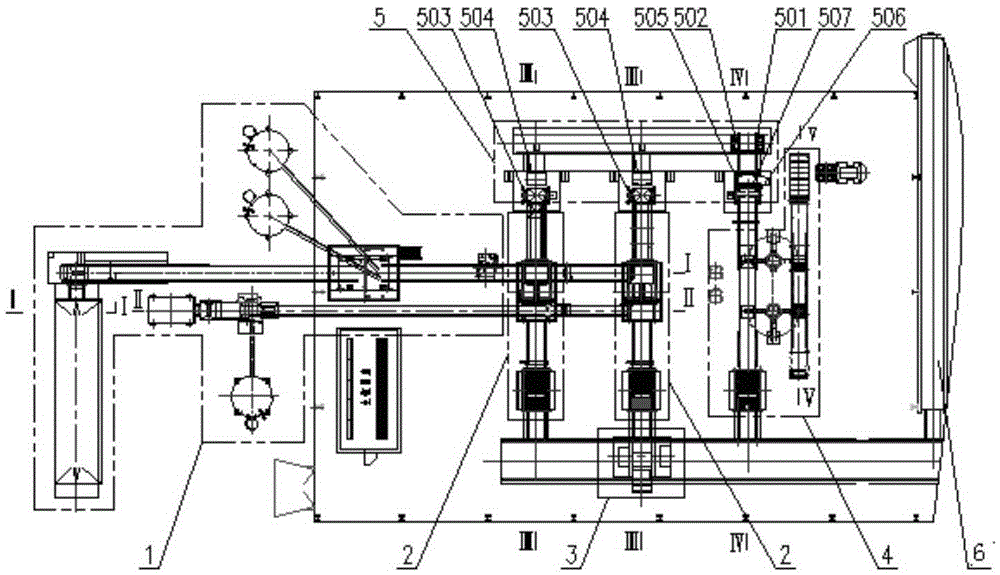

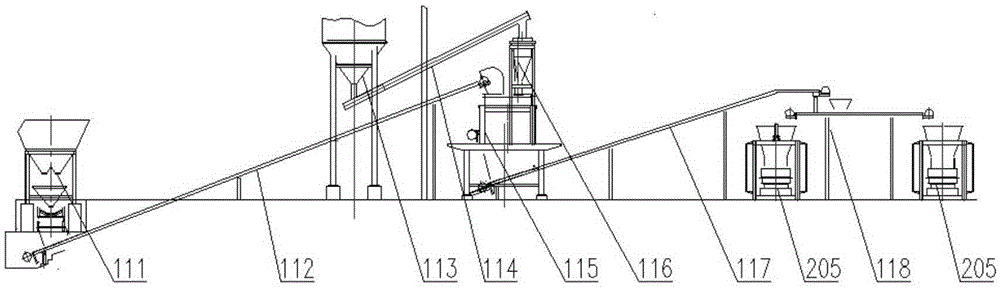

[0031] see figure 1 and figure 2 , the high-quality, high-efficiency double molding machine side-by-side closed-loop automatic block production line described in the present invention includes: batching mixing system 1, two sets of molding machine lifting system 2, one program-controlled transfer kiln car 3, one set of lowering plate Palletizing system 4 and a set of return plate transfer system 5. The ingredient mixing system 1 provides the molding machine with the materials required for molding, and can distribute the materials for the two molding machines according to the needs of the infrared sensor or sonar detection feedback installed in the storage hopper of the molding machine. The molding machine lifting system 2 transports the formed products of the molding machine to the lifting machine, and the program-controlled transfer ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com