A lightweight and durable print roll

A printing roller, light-weight technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of low maintenance costs, and achieve the effect of small workload, low surface wear and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

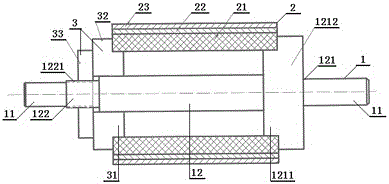

[0024] exist figure 1 Among them, the main body of the lightweight wear-resistant printing roller of the present invention includes a mandrel 1 and a roller body 2, and is characterized in that a limited auxiliary part 3 is added, wherein: the mandrel 1 is made of a corrosion-resistant metal material , the main body includes the left and right end shafts 11 and the middle main shaft 12. On one proximal part 121 of the middle main shaft 12, a limit shoulder A1212 of an inner convex collar A1211 is fixedly arranged, and the other near end 122 is provided with an outer Thread 1221; the main body of the roller body 2 is cylindrical and made of non-metallic material, mainly including a roller base 21 made of carbon fiber material, which is arranged on the outer surface of the roller base 21 and made of low melting point bar An intermediate layer 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com