Flexible assembly system for welding

A flexible and welding technology, applied in auxiliary devices, welding equipment, transportation and packaging, etc., can solve the problems of low plant space utilization, large floor space, and ground congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

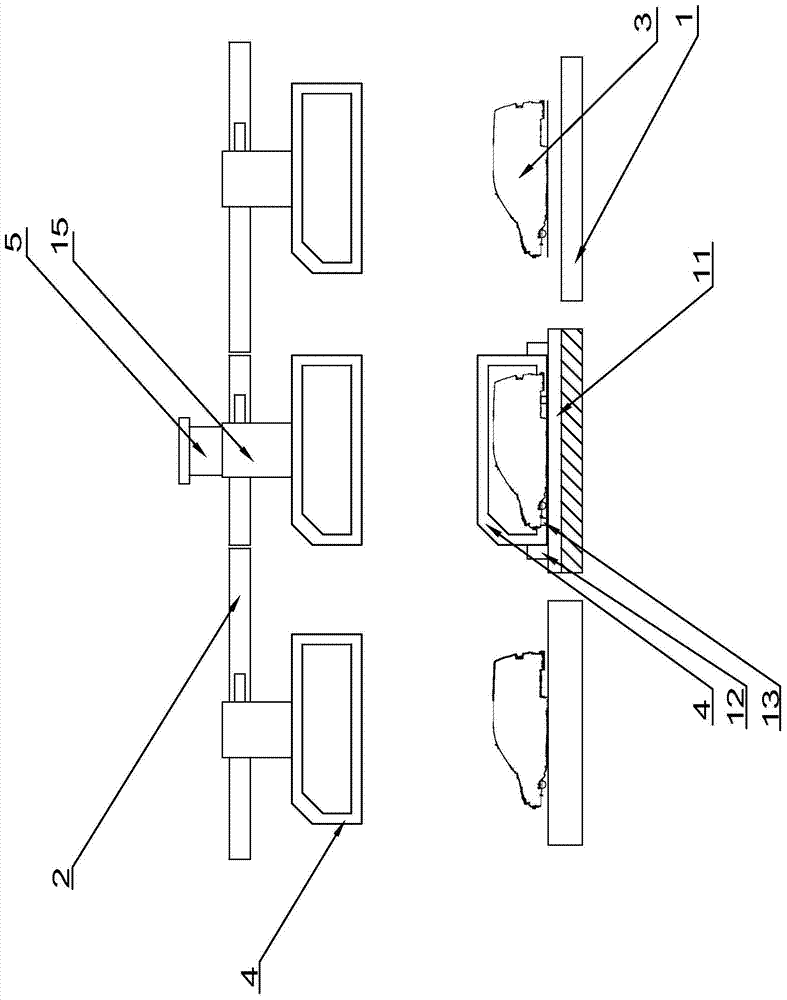

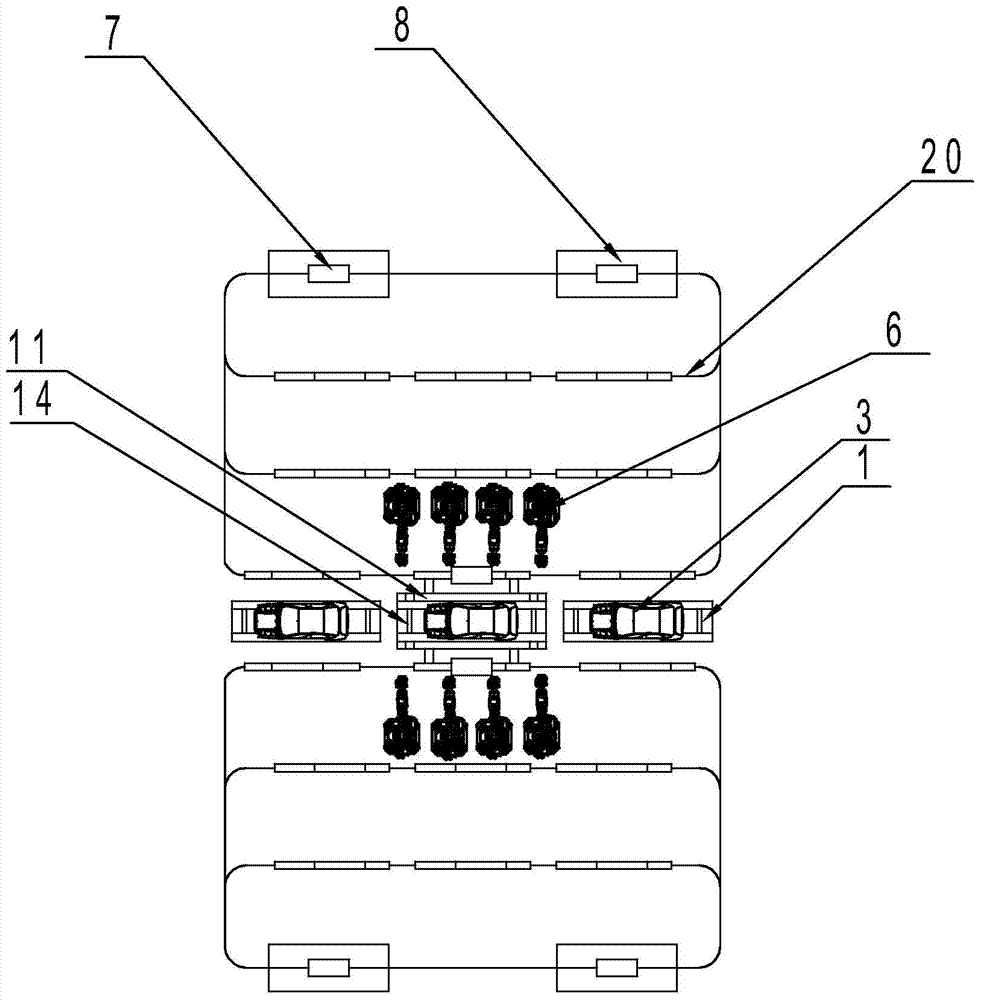

[0015] Reference figure 1 , figure 2 , The present invention is a welding and assembly flexible assembly system, which includes a high-speed rolling bed conveying guide rail 1 with multiple stations fixed on the ground in a straight line and a high-speed rolling bed conveying rail 1 parallel to the high-speed rolling bed conveying rail 1 The upper air fixture conveying track 2. The air fixture conveying track 2 is equipped with an air conveying trolley 15 that can drive the total assembly fixture 4 to transport along the air fixture conveying track 2, and an elevator 5 that can drive the total assembly fixture 4 to lift and move at high speed. The roller bed conveying guide rail 1 is provided with a roller bed 11 that can slide along the high-speed roller bed conveying guide rail 1 in the center.

[0016] This flexible assembly system for welding assembly conveys the assembly fixtures 4 corresponding to different vehicle models through the aerial fixture conveying track 2 to cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com