Method for strengthening nitrogen and phosphorus removal by using hydrolysis and fermentation of mixed sludge of sewage plant

A technology for mixed sludge, nitrogen and phosphorus removal, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Large quantity, process technology has not yet been developed and applied by engineering, etc., to achieve the effect of improving the carbon source structure of the influent, improving the carbon source structure, and increasing the hydrolysis yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

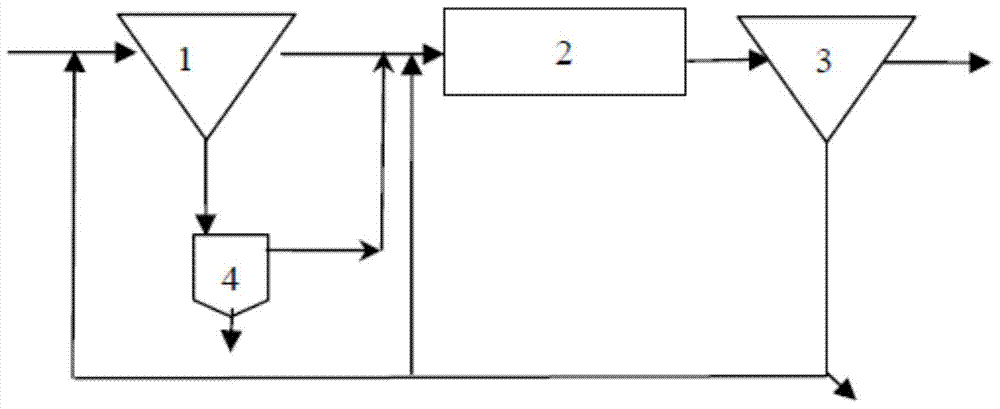

[0045] Such as figure 1 As shown, a method for strengthening denitrification and dephosphorization by hydrolysis and fermentation of mixed sludge from a sewage plant includes the following steps: the sewage that has been initially pretreated by the coarse and fine grids and the aeration grit chamber, and a small amount of reflux from the secondary sedimentation tank 3 The sludge enters the primary sedimentation tank 1 together and undergoes separation and sedimentation, wherein:

[0046] The mixed sludge settled in the primary sedimentation tank 1 enters the hydrolysis tank 4 for hydrolysis and fermentation. The hydrolysis tank 4 includes several processes of pre-stirring, mud feeding, mixing and stirring, sedimentation, and supernatant discharge. Among them, the hydrolyzed sludge is rich in VFA The mixed solution enters the anaerobic zone or anoxic zone of the biological pool 2 to strengthen denitrification and denitrification or anaerobic phosphorus release;

[0047] Among ...

Embodiment 2

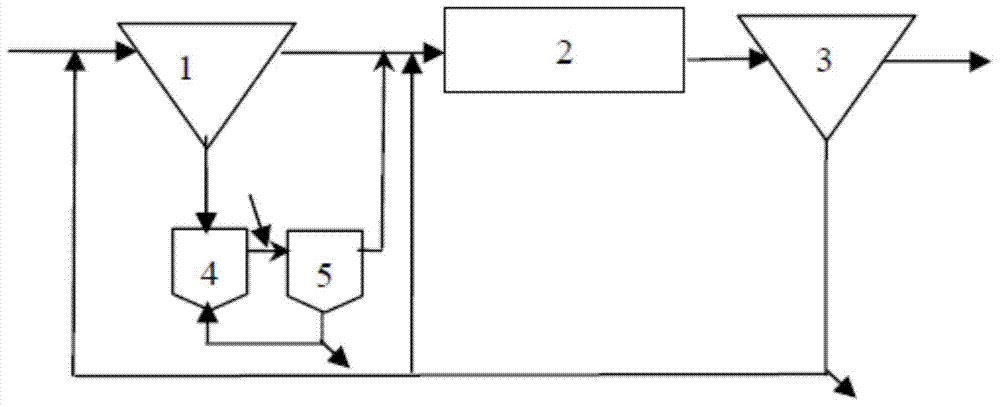

[0052] Such as figure 2 As shown, a method for strengthening denitrification and dephosphorization by hydrolysis and fermentation of mixed sludge from a sewage plant includes the following steps: the sewage that has been initially pretreated by the coarse and fine grids and the aeration grit chamber, and a small amount of reflux from the secondary sedimentation tank 3 The sludge enters the primary sedimentation tank 1 together and undergoes separation and sedimentation, wherein:

[0053] The mixed sludge settled in the primary sedimentation tank 1 enters the hydrolysis tank 4 and the concentration tank 5 successively for hydrolysis and fermentation, wherein the hydrolysis tank 4 is equipped with an agitator and adopts a completely mixed flow to realize anaerobic hydrolysis and fermentation of the mixed sludge, and the concentration tank 5 Static sedimentation is used to mainly complete the mud-water separation of the mixed solution from the hydrolysis tank 4, and the VFA-rich...

Embodiment 3

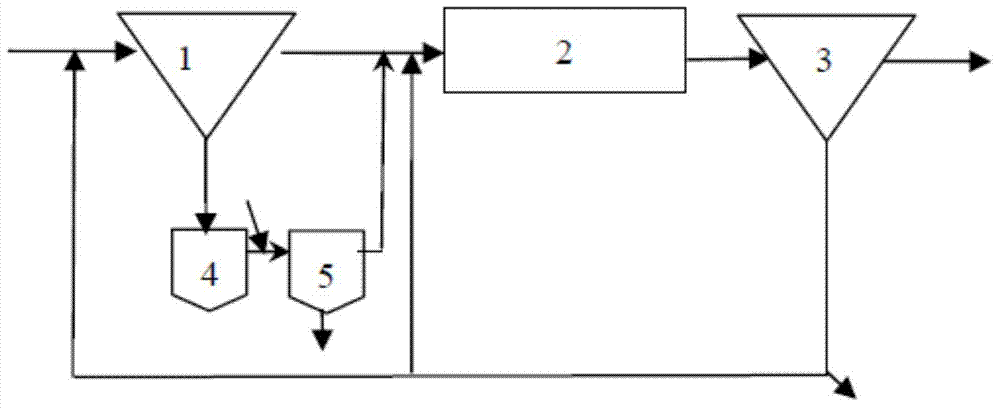

[0059] Such as image 3 It shows that a method for strengthening denitrification and dephosphorization by hydrolysis and fermentation of mixed sludge from a sewage plant includes the following steps: the sewage that has been initially pretreated by the coarse and fine grids and the aeration grit chamber, and a small amount of backflow sewage from the secondary sedimentation tank 3 The mud enters the primary sedimentation tank 1 together and undergoes separation and sedimentation, wherein:

[0060] The mixed sludge settled in the primary sedimentation tank 1 enters the hydrolysis tank 4 and the concentration tank 5 successively for hydrolysis and fermentation, wherein the hydrolysis tank 4 is equipped with an agitator and adopts a completely mixed flow to realize anaerobic hydrolysis and fermentation of the mixed sludge, and the concentration tank 5 Static sedimentation is used to mainly complete the mud-water separation of the mixed solution from the hydrolysis tank 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com