White light-emitting aluminum nitride material injected with rare earth element as well as preparation method and application of white light-emitting aluminum nitride material

A rare earth element and aluminum nitride technology is applied in the field of preparing white light emitting AlN materials by ion implantation, which can solve the problems of inability to achieve white light emission and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

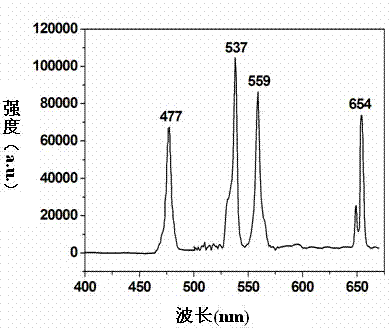

Embodiment 1

[0018] In this embodiment, Pr, Er, and the injection dose of Tm are all 10 14 piece / cm 2 . The thickness of the AlN thin film is 2 microns, which is prepared on the sapphire substrate by MOCVD method. Put the AlN thin film material into an ion implantation device for Pr ion implantation, the implantation conditions are: implantation energy 200KeV, implantation angle 0 0 , with an injection dose of 10 14 pieces / square centimeter. Then the Pr-implanted AlN thin film material is taken out for annealing treatment. The annealing conditions include: normal pressure N 2 Flowing atmosphere, the flow rate is 0.6 sccm, the annealing temperature is 900 ℃, and the annealing time is 2 hours. Put the annealed Pr-implanted AlN thin film material into the ion implantation device for Er ion implantation. The implantation conditions are: the implantation energy range is 200 KeV, and the implantation angle is 0 0 , the implantation dose of Er and the implantation dose of Pr ions keep the s...

Embodiment 2

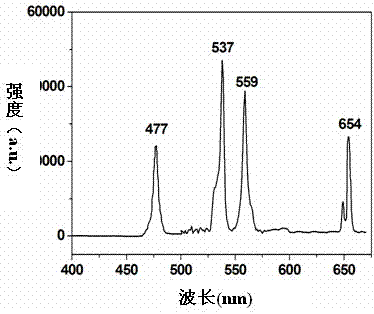

[0021] In this embodiment, Pr, Er, and the injection dose of Tm are all 10 15 piece / cm 2 . The thickness of the AlN thin film is 2 microns, which is prepared on the sapphire substrate by MOCVD method. Put the AlN thin film material into an ion implantation device for Pr ion implantation, the implantation conditions are: implantation energy 300KeV, implantation angle 6 0 , with an injection dose of 10 15 pieces / square centimeter. Then the Pr-implanted AlN thin film material is taken out for annealing treatment. The annealing conditions include: normal pressure N 2 Flowing atmosphere, the flow rate is 0.8 sccm, the annealing temperature is 1000 ℃, and the annealing time is 3 hours. Put the annealed Pr-implanted AlN thin film material into the ion implantation device for Er ion implantation. The implantation conditions are: the implantation energy range is 300 KeV, and the implantation angle is 6 0 , the implantation dose of Er and the implantation dose of Pr ions keep the ...

Embodiment 3

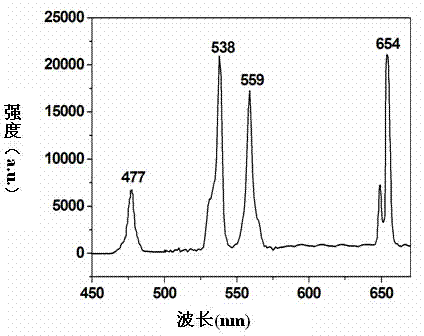

[0024] In the present embodiment, Pr, Er, the injection dosage of Tm are all 10 16 piece / cm 2 . The thickness of the AlN thin film is 2 microns, which is prepared on the sapphire substrate by MOCVD method. Put the AlN thin film material into an ion implantation device for Pr ion implantation, the implantation conditions are: implantation energy 400KeV, implantation angle 10 0 , with an injection dose of 10 16 pieces / square centimeter. Then the Pr-implanted AlN thin film material is taken out for annealing treatment. The annealing conditions include: normal pressure N 2 Flowing atmosphere, the flow rate is 1.0 sccm, the annealing temperature is 1050 ℃, and the annealing time is 4 hours. Put the annealed Pr-implanted AlN thin film material into the ion implantation device for Er ion implantation. The implantation conditions are: the implantation energy range is 400 KeV, and the implantation angle is 10 0 , the implantation dose of Er and the implantation dose of Pr ions ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com