Method for carrying out cyanide-free cuprous brass electroplating on steel cord and method for passivating brass coating

A cyanide-free cuprous and brass coating technology, which is applied in the field of steel cord surface modification, can solve the problems of unstable coating composition, complex process, poor corrosion resistance, etc., shorten the production process, stabilize the coating composition, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

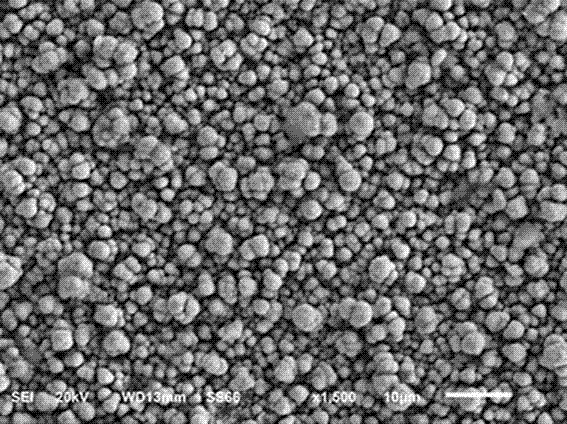

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the steel cord of the present embodiment is cyanide-free copper-plated brass according to the following steps:

[0020] (1) Preparation of cyanide-free cuprous electroplating brass solution: a. The concentration of cuprous oxide is 3~30g / L, the concentration of antioxidant is 0.2~20.0g / L, and the concentration of cuprous complexing agent is 15 ~150g / L, the concentration of auxiliary complexing agent is 10~100g / L and weighs cuprous oxide, antioxidant, cuprous complexing agent and auxiliary complexing agent respectively; The copper complexing agent and the auxiliary complexing agent are successively dissolved in 60 mL / L of acetic acid solution, heated and stirred until dissolved to obtain solution A; c, the cuprous oxide weighed in step a is added to solution A, stirred until dissolved, After standing for 24 hours, solution B was prepared; d, the concentration of zinc acetate was 5~40g / L, the concentration of sodium acetate was 40~50g / L, and the c...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the antioxidant described in step (1) a and b is uric acid, vitamin C, sodium hypophosphite, hydroquinone, pyrocatechol Or one of resorcinol, the concentration is 0.5~15.0g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the cuprous complexing agent described in a and b of step (1) is thiosemicarbazide, tetramethylthiourea, thiourea or One kind of ethylene thiourea or a combination of several of them, the concentration is 18~145g / L. Others are the same as in the first or second embodiment.

[0026] When the cuprous complexing agent of this embodiment is a composition, various cuprous complexing agents are combined in arbitrary ratios.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com