Preparation method of grafting modified beta-cyclodextrin aromatic finishing agent

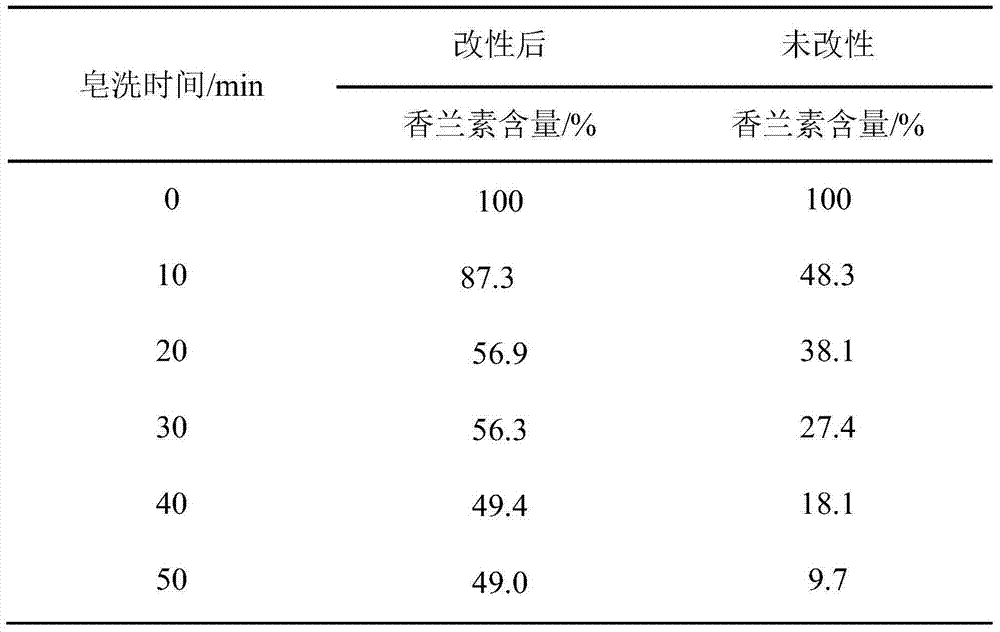

An aromatic finishing agent and graft modification technology, which is applied in fiber treatment, textiles and papermaking, plant fiber, etc., can solve the problem of short fragrance retention time of β-cyclodextrin aromatic finishing agent and lack of β-cyclodextrin and fabrics. Reactivity and other issues, to achieve good fragrance effect, enhance the effect of water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of graft modified β-cyclodextrin fragrance finishing agent of the present invention, specifically comprises the following steps:

[0022] Step 1: Add β-cyclodextrin, acrylic acid and distilled water into the reactor according to the mass ratio of 1:0.2~1.4:4, mix evenly at 40~80℃, and then add dropwise at a concentration of 0.010mol within 20~30min / L~0.030mol / L potassium persulfate aqueous solution, the mass ratio of potassium persulfate to β-cyclodextrin is 1:20~40; after the dropwise addition, keep it warm for 40~150min, and purify the obtained product with absolute ethanol , after the precipitate is filtered, it is fully washed with acetone and dried in a vacuum oven at 45-50°C for 24-48 hours to obtain a β-cyclodextrin-g-polyacrylic acid graft polymer with a grafting rate of 7.301%-15.601%. ;

[0023] Step 2: Add the β-cyclodextrin-g-polyacrylic acid graft polymer obtained in step 1 and distilled water into the reactor according to the...

Embodiment 1

[0028] Add β-cyclodextrin, acrylic acid and distilled water in a mass ratio of 1:0.8:4 into a three-necked flask equipped with a stirrer, a condenser, and a feeding device, heat up to 40°C and mix evenly, and add dropwise within 30 minutes The concentration of potassium persulfate aqueous solution is 0.025mol / L, the mass ratio of potassium persulfate to β-cyclodextrin is 1:20, after the potassium persulfate aqueous solution is added dropwise, keep warm for 120min. After the reaction, precipitate and purify 3 times with absolute ethanol, then wash the precipitate fully with acetone, and dry the product in a vacuum oven at 50°C for 24 hours to obtain β-cyclodextrin-g-polyethylene with a grafting rate of 15.601%. Acrylic graft polymer;

[0029] Add the β-cyclodextrin-g-polyacrylic acid graft polymer and distilled water obtained in step 1 into a three-necked flask equipped with a stirrer, a condenser, and a feeding device according to a mass ratio of 1:11, dissolve at 50°C, and th...

Embodiment 2

[0031] Add β-cyclodextrin, acrylic acid and distilled water in a mass ratio of 1:0.8:4 into a three-necked flask equipped with a stirrer, a condenser, and a feeding device, heat up to 60°C and mix evenly, and add dropwise within 30 minutes The potassium persulfate aqueous solution with a concentration of 0.025mol / L was added, and the mass ratio of potassium persulfate to β-cyclodextrin was 1:20. After the potassium persulfate aqueous solution was added dropwise, the reaction was incubated for 40 minutes. After the reaction, precipitate and purify with absolute ethanol three times, then wash the precipitate fully with acetone, and dry the product in a vacuum oven at 45°C for 48 hours to obtain β-cyclodextrin-g-polyethylene with a grafting rate of 14.597%. Acrylic graft polymer;

[0032]Add the β-cyclodextrin-g-polyacrylic acid graft polymer and distilled water obtained in step 1 into a three-necked flask equipped with a stirrer, a condenser, and a feeding device according to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com