Construction method for basement construction bottom plate

A construction method and construction technology, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as bottom plate cracking, difficulty in compacting, and hidden dangers of waterproofing, and achieve the effects of quality assurance, cost reduction, and avoidance of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention are further described below by means of the accompanying drawings and examples.

[0025] The construction method of the basement structure floor of the present invention comprises the following steps:

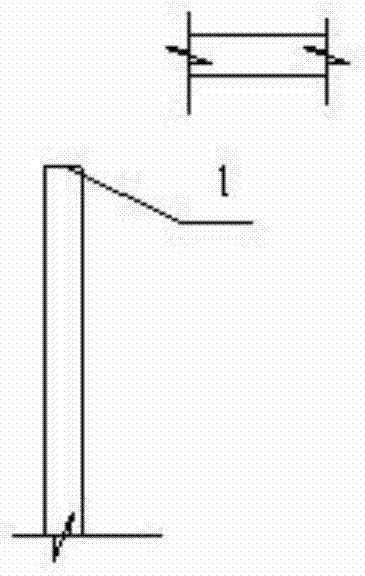

[0026] (1) if figure 1 As shown, according to the common method of pouring and ramming shear walls and columns, the outer wall columns of the shear wall are normally constructed to 550mm below the structural floor, leaving a construction joint 1;

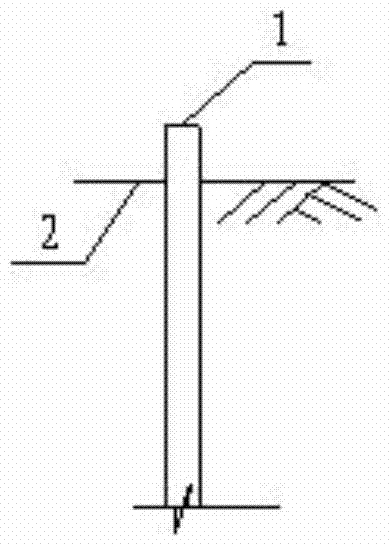

[0027] (2) if figure 2 As shown, the internal and external backfill soil shall be filled to 400 mm below the construction joint 1 of the poured shear wall and column and shall be compacted in time as much as possible;

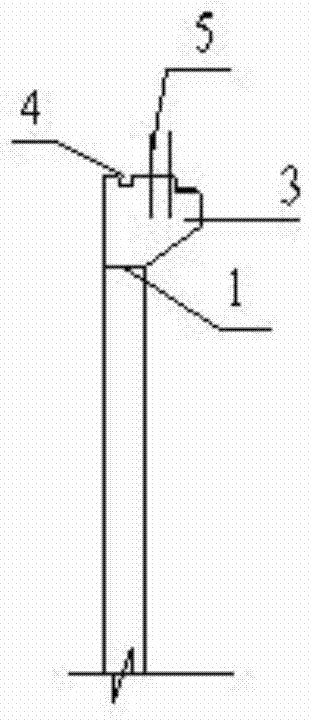

[0028] (3) if image 3 As shown, construct the corbel 3 according to the design size, pay attention to leave the groove 4 and insert the connecting steel bar 5;

[0029] (4) if Figure 4 As shown, in accordance with the normal construction sequence, constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com