Oil injection pump with centrifugal regulator

A technology of fuel injection pump and adjustment mechanism, which is applied in the direction of fuel injection pump, machine/engine, fuel injection device, etc., can solve the problems of friction and increase of installation length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

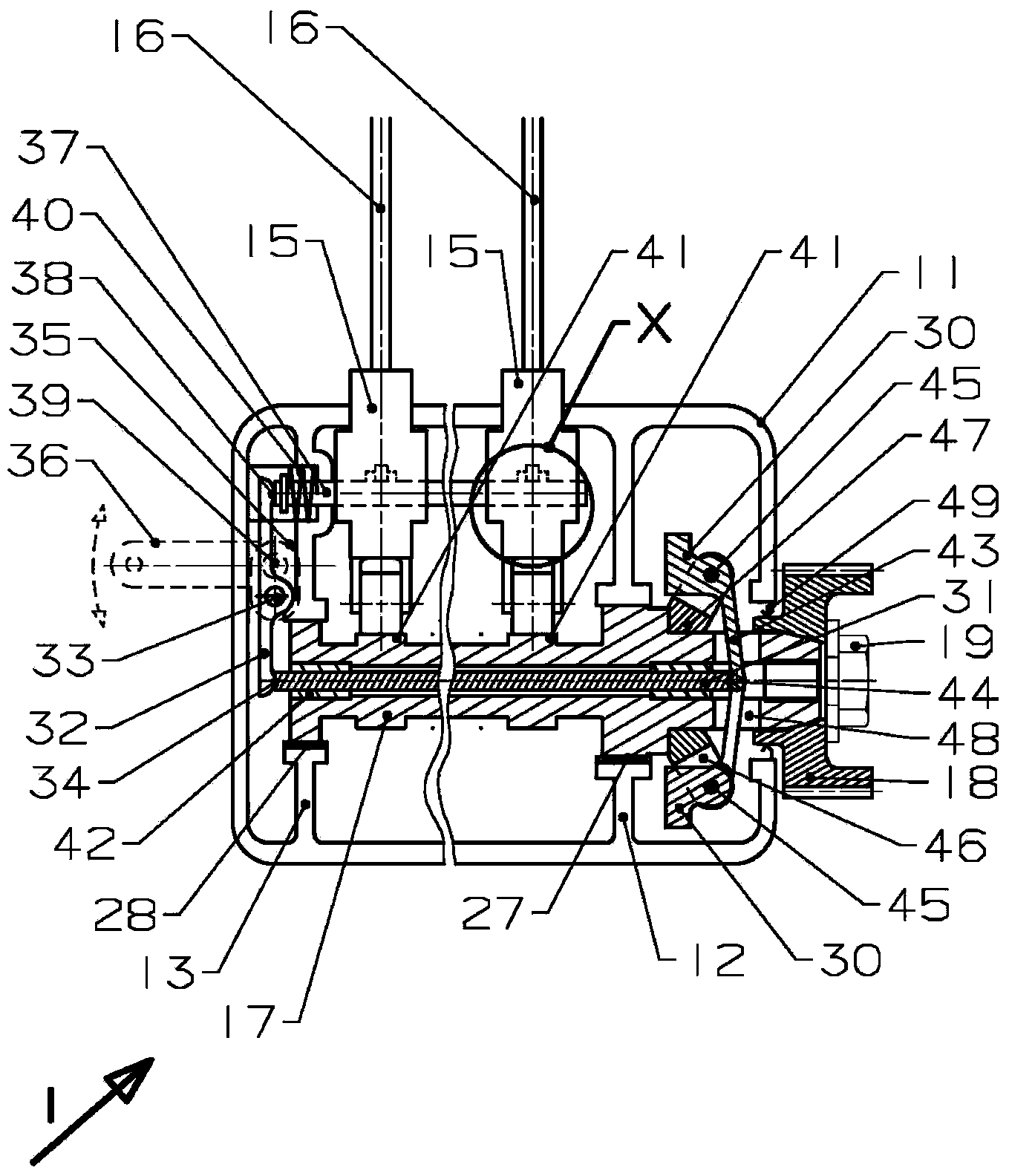

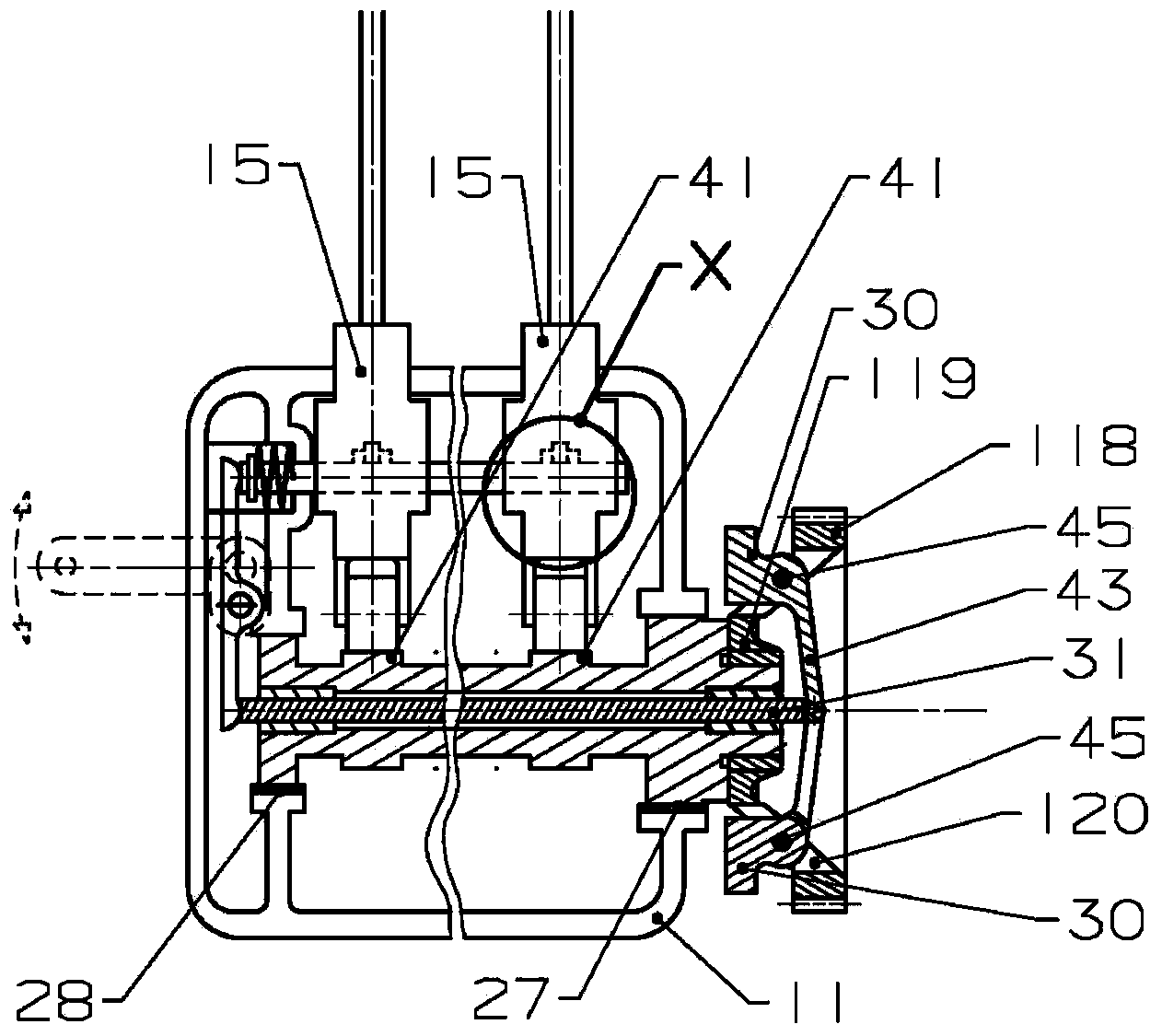

[0016] exist figure 1 The middle represents the fuel injection pump installed in the internal combustion engine (not shown in the figure) represented by the symbol 1. Its housing 11 constitutes a front bearing wall 12 and a rear bearing wall 13 and accommodates a number of pump devices 15 corresponding to the number of cylinders of the internal combustion engine. Fuel injection lines 16 lead from these pump devices 15 to the respective cylinders. It is also possible to have only a single pump device 15 . Mounted in bearings 27 and 28 in bearing walls 12 and 13 is an oil-injected camshaft 17 which extends out of housing 11 over front bearings 27 and at its end fits drive gear 18 . The drive gear 18 is driven by the crankshaft of the internal combustion engine through meshing or through a chain or toothed belt (both not shown in the figure). This is done by fixing the concentric bolt 19 to the injection camshaft 17 .

[0017] The injection camshaft 17 is hollow inside throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com