Elevated farmland work machine

A working machine and farmland technology, applied in agriculture, animal husbandry, devices for catching or killing insects, etc., can solve the problems of non-adjustable center of gravity, unstable balance, single function, etc., and achieve convenient transportation and storage, and reasonable structural design , good balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

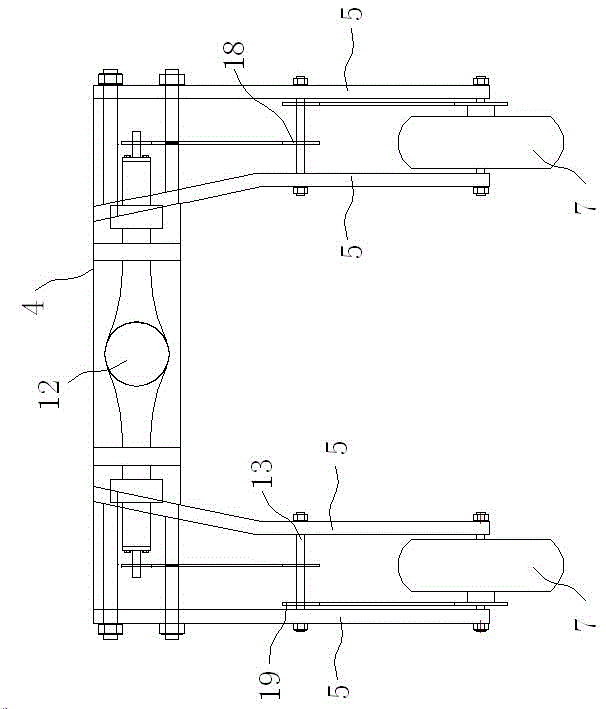

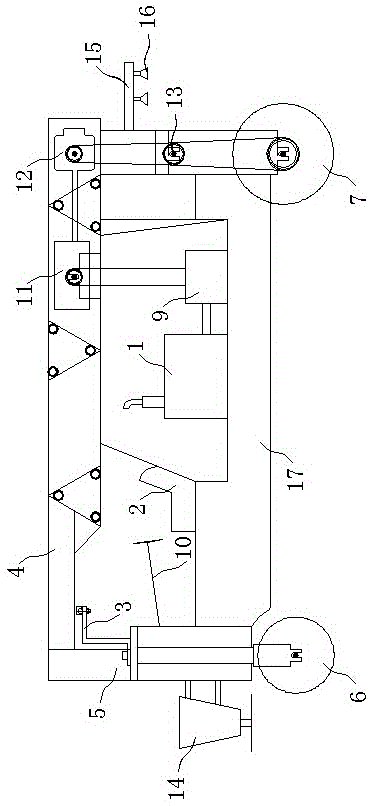

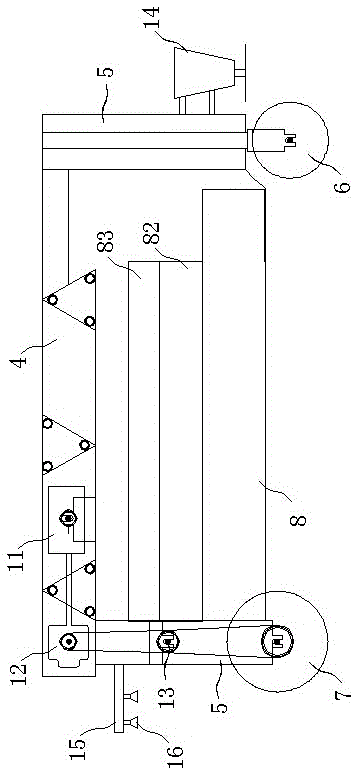

[0016] Attached below figure 1 , attached figure 2 and attached image 3 The overhead farm work machine of the present invention will be further described.

[0017] The overhead farm work machine of the present invention is composed of a frame, an engine 1, a driver's seat 2, a steering wheel 6 and a power wheel 7. The frame is composed of a top scaffold 4 and a support frame 5, and the whole is in the shape of an elevated bridge. The front and rear of the two sides of the frame 4 are fixed with support frames 5, a total of four support frames 5, the bottom of the two support frames at the front end are provided with steering wheels 6, and the bottoms of the two support frames at the rear end are provided with power wheels 7. There are more than one set of water tanks I8 on the horizontal frame between the steering wheel 6 and the power wheel 7 on the same side, and a water tank II17 on the horizontal frame between the steering wheel 6 and the power wheel 7 on the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com