Method for increasing product yield of bean product

A technology for soybean products and yield, applied in the field of improving protein extraction rate, can solve the problems of low efficiency, complex production process, low utilization rate of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

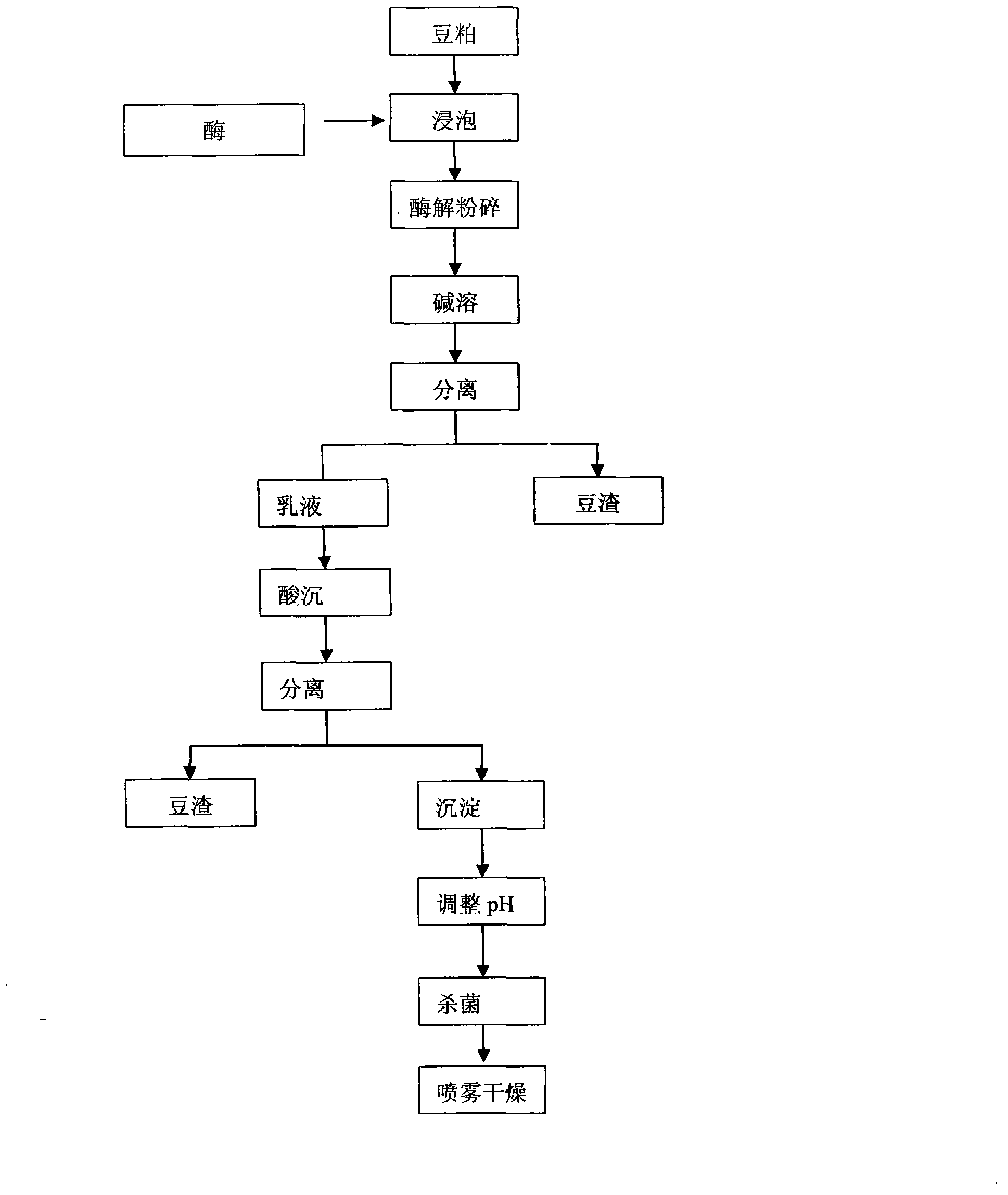

[0011] Example 1: Production of Protein Isolate

[0012] Step 1: Add 1 soybean meal into 10 kilograms of water, add 1 g of enzyme preparation, heat up to 50 degrees, grind while stirring, and keep warm for 30 minutes.

[0013] Step 2: adding lye to the above extract, adjusting the pH to 8.5, stirring and extracting for 2 hours.

[0014] Step 3: Centrifuge the above extract to obtain an emulsion.

[0015] Step 4: Adjust the pH of the emulsion to 4.5 to obtain egg white.

[0016] Step 5: Adjust the pH of protein puree to 7.0.

[0017] Step 6: The protein paste is sterilized by flash steaming at 140 degrees.

[0018] Step 7: Spray-dry the protein paste at 150 degrees after cooling down to 55 degrees.

Embodiment 2

[0019] Example 2: Production of Protein Isolate

[0020] Step 1: Add 1 kg of soybean meal to 9 kg of water, add lye, adjust the pH to 8.5, raise the temperature to 50 degrees, and stir for 1 hour to extract.

[0021] Step 2: Adjust the pH of the above extract to 6, add 1 g of enzyme preparation, grind while stirring, and keep warm for 30 minutes.

[0022] Step 3: Centrifuge the above extract to obtain an emulsion.

[0023] Step 4: Adjust the pH of the emulsion to 4.5 to obtain egg white.

[0024] Step 5: Adjust the pH of protein puree to 7.0.

[0025] Step 6: The protein paste is sterilized by flash steaming at 140 degrees to kill enzymes.

[0026] Step 7: Spray-dry the protein paste at 150 degrees after cooling down to 55 degrees.

Embodiment 3

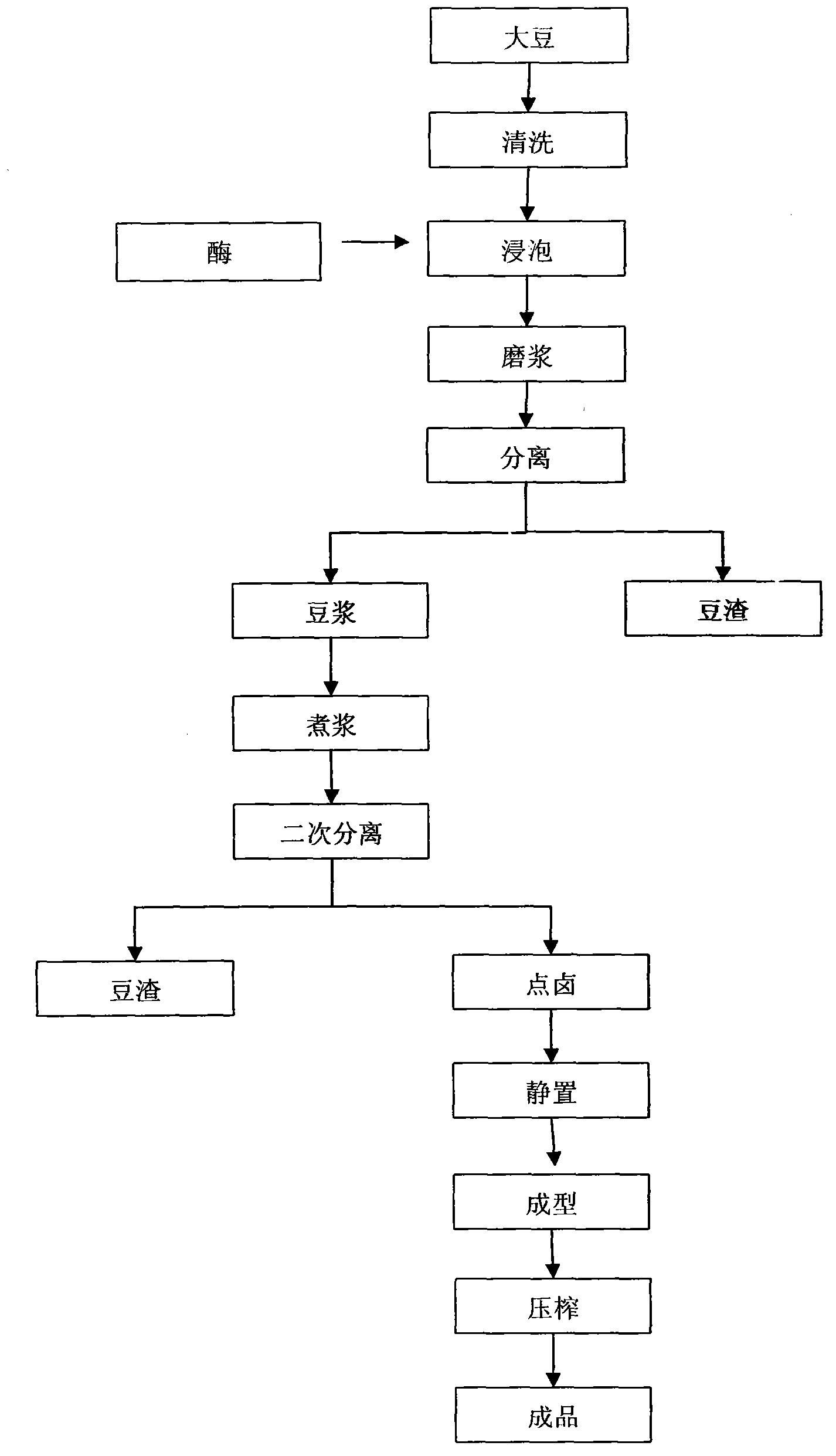

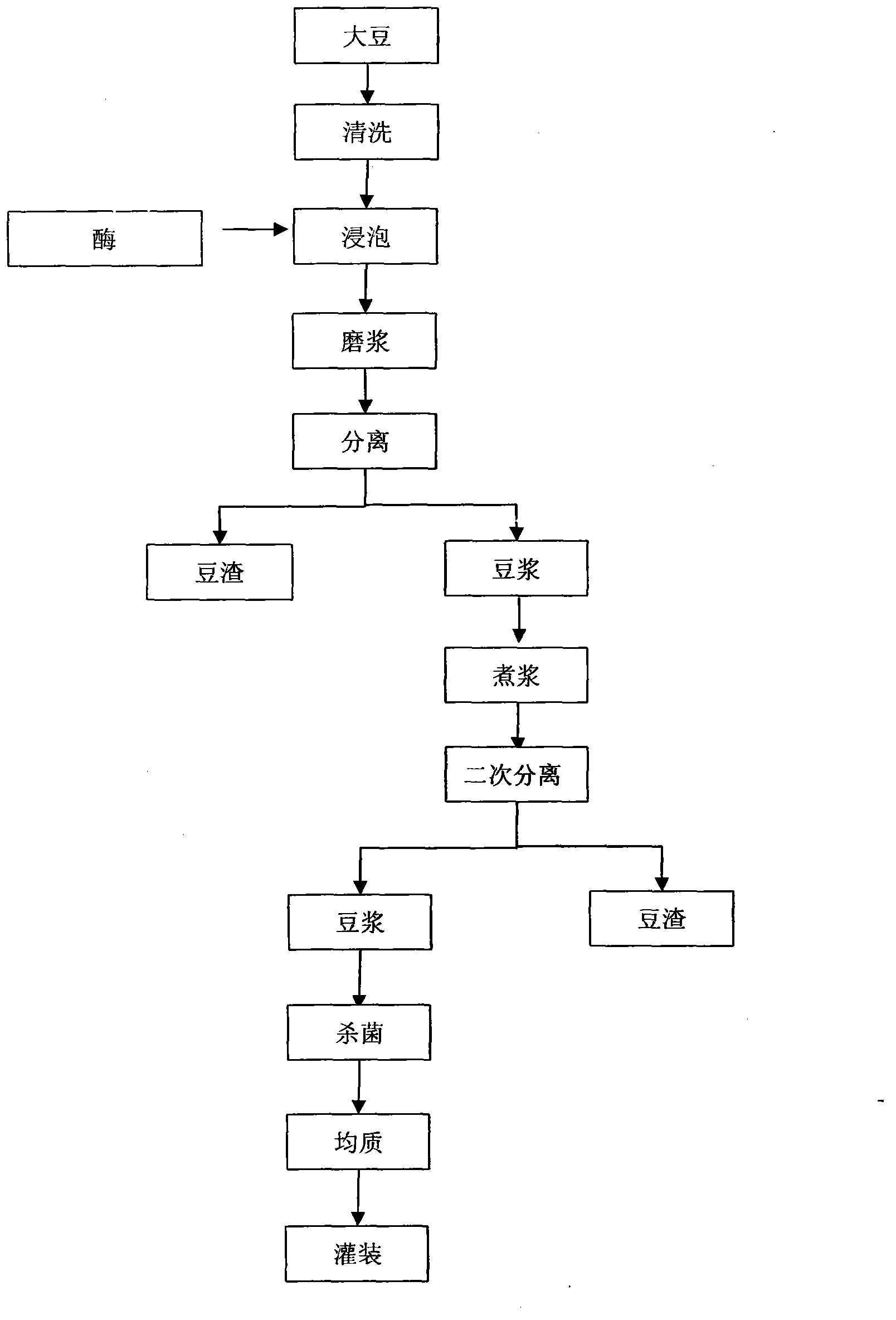

[0027] Embodiment 3: tofu production

[0028] Step 1: Add 1 kg of soybeans to 2 kg of water, then add 1 gram of enzyme preparation, and soak for 5 hours.

[0029] Step 2: Add 1 kg of soybeans to 6 kg of water for grinding.

[0030] Step 3: Separating the bean dregs with a separator to obtain soybean milk.

[0031] Step 4: Heat the soybean milk to 100 degrees to cook the milk.

[0032] Step 5: The soy milk is separated into fine bean dregs again, and the temperature is lowered to 85 degrees.

[0033] Step 6: Add bittern to the soy milk, the amount added is 1 gram of bittern.

[0034] Step 7: Let stand for 30 minutes.

[0035] Step 8: Put the bean brain into the mold and shape it.

[0036] Step 9: Squeeze for 30 minutes to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com