Concentrating table with bottom capable of sliding

A technology of ore trough and transmission box, which is applied in the field of beneficiation shaking table, can solve the problems of large occupied area, achieve the effect of small occupied area, high mineral separation rate, and solve the problem of lower beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

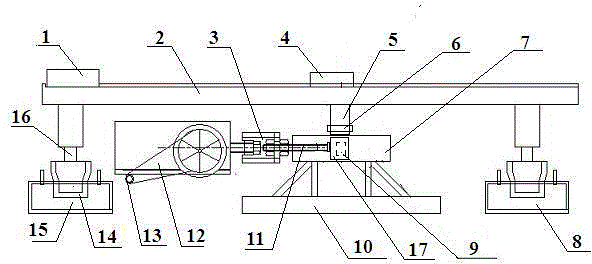

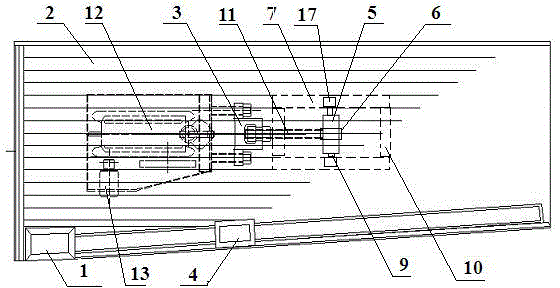

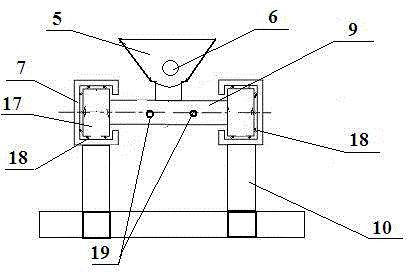

[0013] In the figure, a bottom sliding beneficiation shaking table includes a transmission box 12, a motor 13, a slope regulator 8, a bed surface 2, a mine tank 1, a water tank 4, a connecting screw 11, and a machine base. It is characterized in that the transmission box 12 1. The motor 13 is installed on the lower frame of the bed surface. The connecting part between the transmission box 12 and the bed surface includes a connecting mechanism and a stabilizing mechanism. 6. One end is connected to the connection plate 5, and the other end is connected to the linkage seat; the stabilizing mechanism includes a positioning cross arm 9, a slide rail 7, and a slide rail fixing frame 10. The middle part of the cross arm 9 is fixed on the connecting shaft 6, and the two ends of the cross arm 9 are inserted Inside the rail 7, balls are installed on the three sides where the end of the cross arm 9 is in contact with the slide rail 7 to ensure smooth sliding of the cross arm. Stable; to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com