Horizontal sand-ejecting and parting clay-bonded sand automatic moulding machine

A technology of horizontal parting and horizontal sand shooting, applied in molding machines, manufacturing tools, casting and molding equipment, etc., can solve the problems of difficulty in making large sand molds, prone to collapse or damage, poor sand uniformity, etc. Reliable combination or separation, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

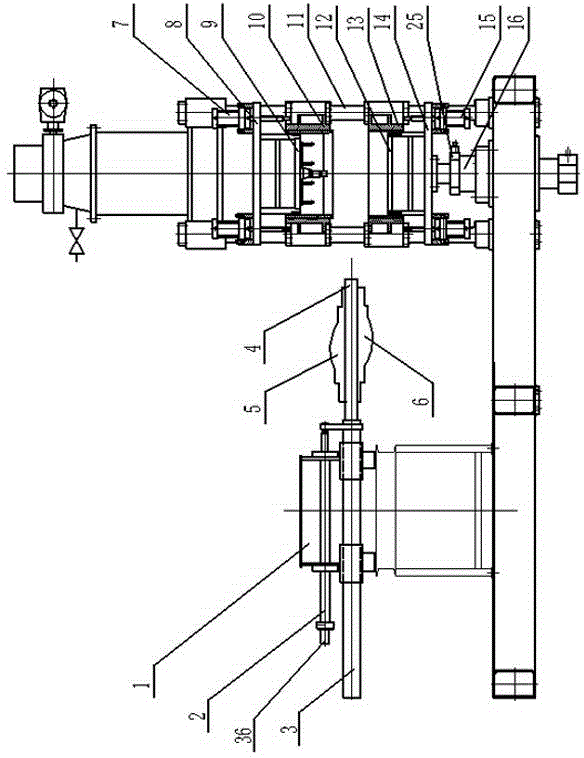

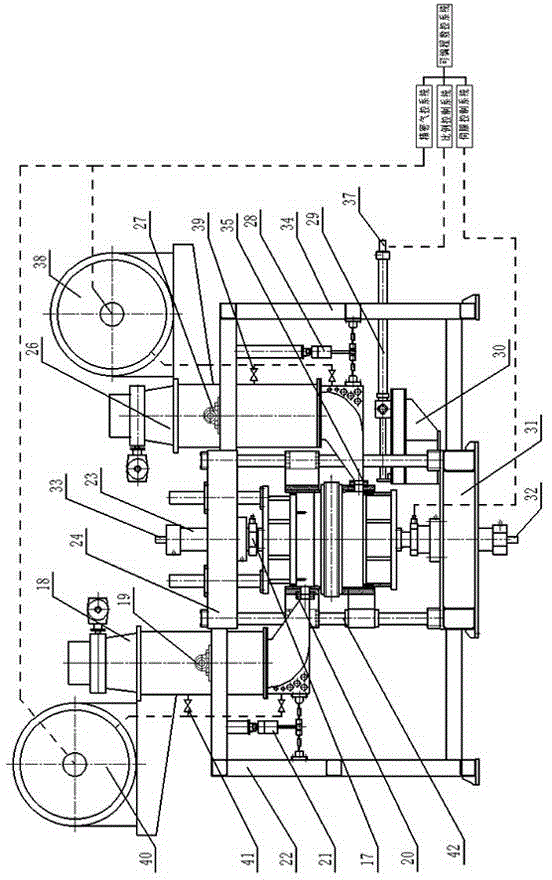

[0015] The automatic molding machine for horizontal sand injection and horizontal splitting of clay sand according to the present invention comprises a main frame 42, an upper sand box 10, a lower sand box 13, an upper compacting head 9, a lower compacting head 12, a plate turning and pushing mechanism 1, Upper sand box injection cylinder 18, lower sand box injection cylinder 26, sand mold pushing mechanism 30, upper compaction cylinder 23, lower compaction cylinder 16, upper sandbox servo vibration cylinder 17, lower sandbox servo vibration cylinder 25. The machine's upper and lower compaction cylinders, pattern plate push cylinders, sand mold push cylinders, upper and lower sand box servo vibration cylinders all adopt hydraulic proportional and servo control technology, which greatly improves the response speed, control precision and molding efficiency of the equipment. The upper sand box and the lower sand box of the machine are equipped with independent sand blasting cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com