Electrochemical machining high frequency pulse power source based on SOPC technology

A high-frequency pulse and power supply technology, which is applied in the field of high-frequency pulse power supply for electrolytic processing, can solve problems such as not being very suitable, low processing precision of DC electrolytic power supply and inverter rectified electrolytic power supply, and difficult to meet high-precision electrolytic processing. Achieve the effects of improving stability, improving processing accuracy and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail below with reference to the drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

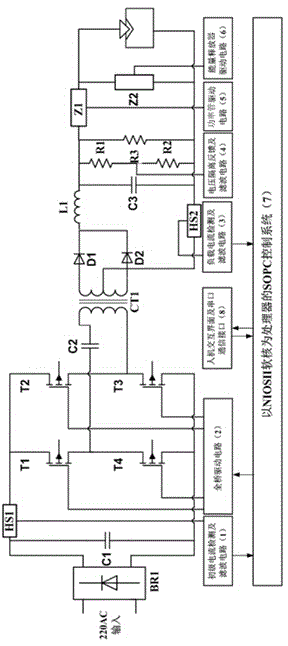

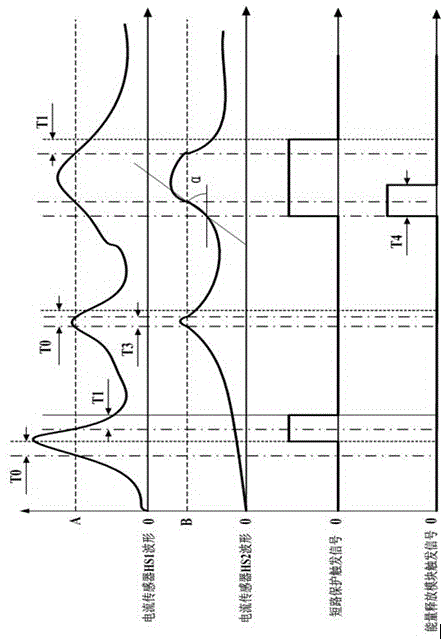

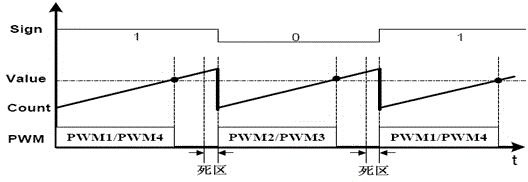

[0038] Reference figure 1 As shown, the present invention provides a high-frequency pulse power supply for electrochemical machining based on SOPC technology, which includes an AC input terminal, a primary rectifier filter circuit, a full-bridge inverter circuit, a high-frequency transformer circuit, a secondary rectifier filter circuit, and a chopper. Circuit, pulse output terminal, energy release device, load current detection circuit and control system.

[0039] Among them, the AC input terminal is connected to 220V single-phase AC power.

[0040] The primary rectification filter circuit is connected to the AC input terminal, and is used to rectify and filter the AC power input from the AC input terminal to form DC power. The primary rectifier filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com