Nano SiO2 microsphere, water-repelling agent, preparation methods of nano SiO2 microsphere and water-repelling agent, and water-repelling glass

A water repellent, microsphere technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low contact angle, complex process, poor durability, etc., and achieve low cost and process. Simple, safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

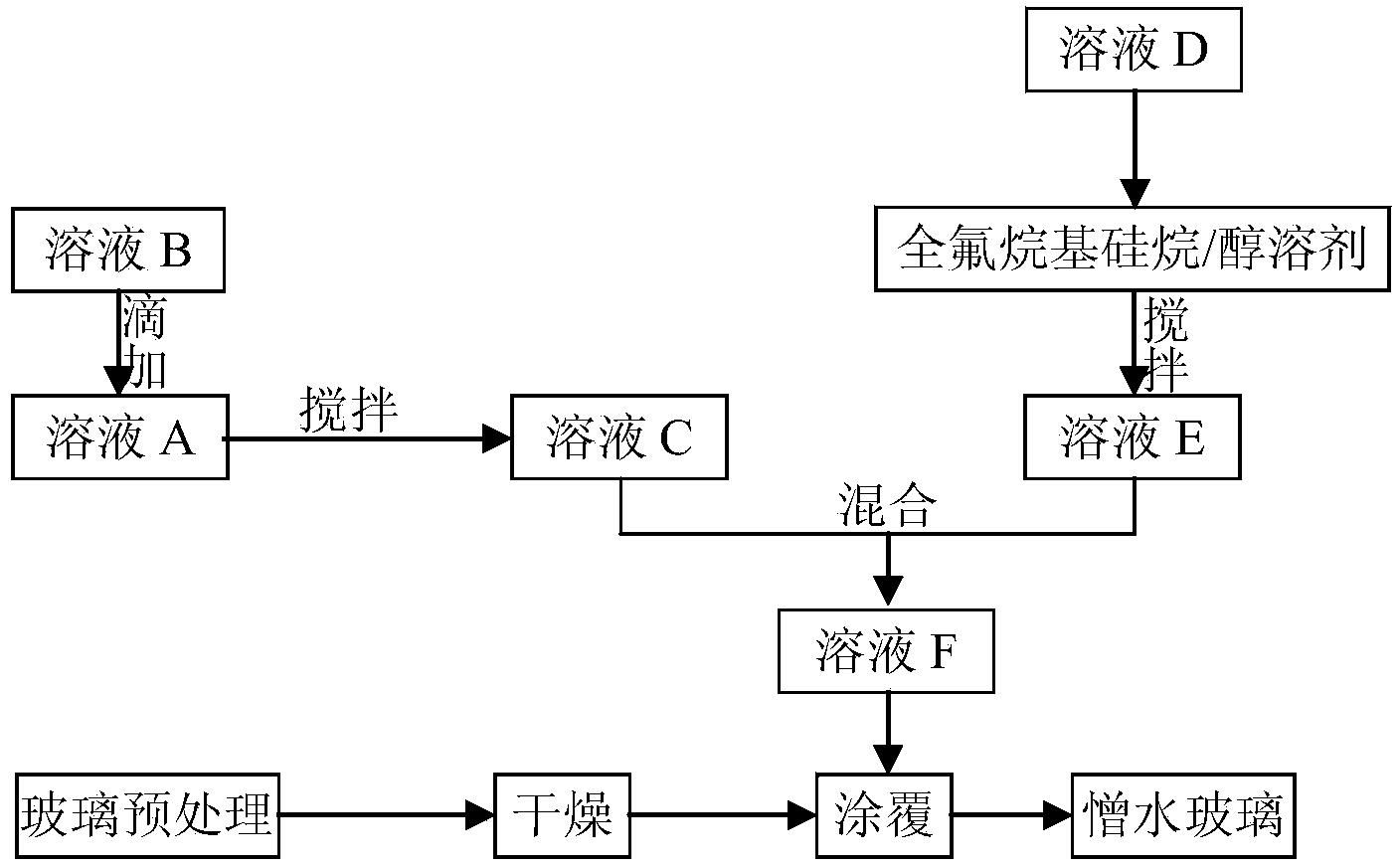

[0056] A kind of nano-SiO 2 Microsphere preparation method, comprising the following steps:

[0057](1) Ethyl orthosilicate is dispersed in aqueous alcohol solution to form solution A, wherein the mass ratio of water is 1.8% to 2.0%, the mass ratio of ethyl orthosilicate is 0.4% to 2.6%, and the balance is Alcohol; the water is deionized water or distilled water; the alcohol is one of ethanol, n-propanol, isopropanol, n-butanol and other alcoholic solvents or a mixture of several of them.

[0058] (2) Add concentrated ammonia water to alcohol to form alcoholic ammonia solution B, and NH in the alcoholic ammonia solution B 3 The mass percentage content is 3.1%-7.2%, and the balance is alcohol solvent; the alcohol is one of alcohol solvents such as ethanol, n-propanol, isopropanol, n-butanol, or a mixture of several of them.

[0059] (3) At room temperature, add solution B to solution A at a rate of 20-45 μl / min, stir while adding solution B to solution A, the stirring speed i...

Embodiment 1

[0071] Preferred Embodiment 1: This embodiment provides a nano-SiO 2 The preparation method of microsphere, hydrophobic modifier and hydrophobic glass comprises the following steps:

[0072] (1) Ethyl orthosilicate is dispersed in ethanol / distilled water to obtain solution A, wherein the mass percentage content of ethyl orthosilicate is 1.88%, the mass percentage content of distilled water is 2.53%, and the balance is ethanol; concentrated ammonia water is added to ethanol , get NH 3 Solution B with a mass percent content of 6.60%; add solution B to solution A at a rate of 20 μl / min, and stir at 1000 rpm at the same time. After all solution B is added to solution A, continue to stir for 30 minutes, and then leave it open 72h to get solution C, SiO in solution C 2 The particle size of the microspheres is about 75nm.

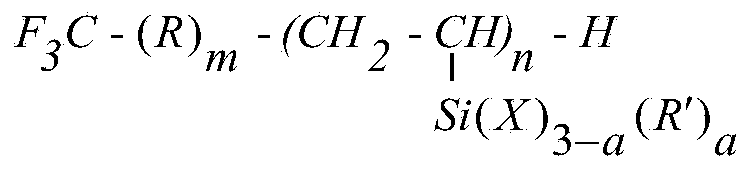

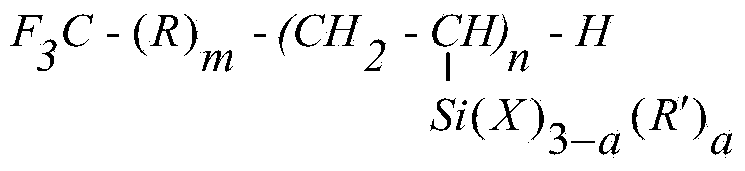

[0073] (2) Mix hydrochloric acid and distilled water in a ratio of 1:1 to obtain solution D; Mix with ethanol to obtain a perfluoroalkylsilane / alcohol mixed ...

Embodiment 2

[0076] Preferred embodiment two: this embodiment provides a nano-SiO 2 The preparation method of microsphere, hydrophobic modifier and hydrophobic glass comprises the following steps:

[0077] (1) Ethyl orthosilicate is dispersed in ethanol / distilled water to obtain solution A, wherein the mass percentage content of ethyl orthosilicate is 1.90%, the mass percentage content of distilled water is 1.63%, and the balance is ethanol; concentrated ammonia water is added to ethanol , get NH 3 Solution B with a mass percentage content of 5.55%; add solution B to solution A at a speed of 25 μl / min, and stir at 800 rpm at the same time. After all solution B is added to solution A, continue to stir for 60 minutes, and then leave it open 72h to get solution C, SiO in solution C 2 The particle size of the microspheres is about 63nm.

[0078] (2) Mix hydrochloric acid and distilled water in a ratio of 1:1 to obtain solution D; Mix with ethanol to obtain a perfluoroalkylsilane / ethanol m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com