Heatproof oil-resistant phenolic epoxy static anticorrosive paint and preparation method thereof

A technology of phenolic epoxy conductive and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve problems such as low resistivity, corrosion perforation, and doubtful range of resistivity, and achieve excellent tolerance , Improve heat resistance, excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 preparation method:

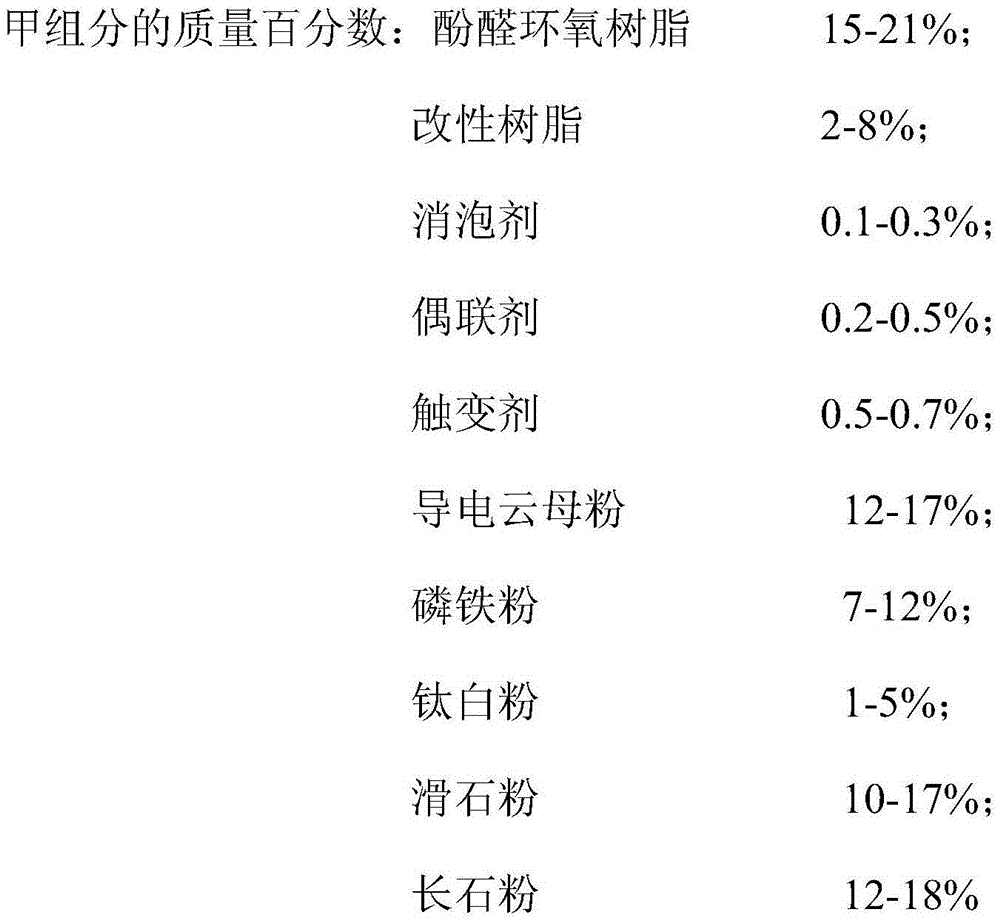

[0035] Add 15 parts of novolac epoxy resin, 8 parts of modified resin, 0.2 parts of defoamer, 0.2 parts of coupling agent in the material tank, and disperse evenly, add 15 parts of feldspar powder, 17 parts of talc powder, 5 parts of titanium dioxide, 12 parts 1 part of ferrophosphorus powder, disperse at high speed for about 20 minutes, make the paint temperature reach 40-55 ℃, add 0.5 parts of thixotropic agent, and disperse at high speed for about 20 minutes, control the fineness ≤ 80 μm, add 15.1 parts of solvent and stir evenly, add 12 parts of conductive Mica powder, disperse at low speed for about 10 minutes, and filter with a 100-mesh filter to obtain the first component of the coating. Add 65 parts of curing agent and 35 parts of solvent into the material tank and mix evenly to obtain the second component of the coating. According to component A: component B = 10:1 mixing is the heat-resistant, oil-resistant and static-conduc...

Embodiment 2

[0036] Embodiment 2 and embodiment 3 preparation methods are the same as embodiment 1.

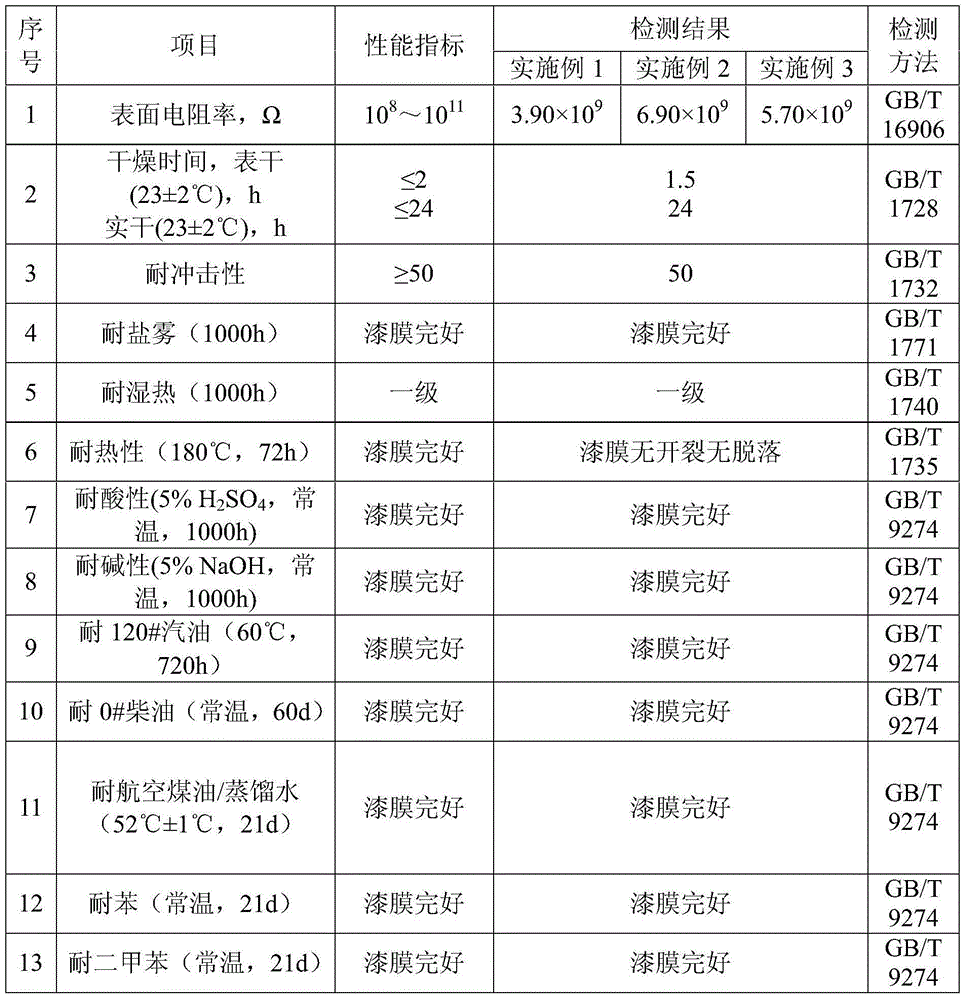

[0037] The coating prepared in the embodiment is prepared as a model, and the performance is tested, as shown in Table 2.

[0038] The performance data of table 2 embodiment

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com