Methanol denaturing agent, as well as preparation method and application thereof

A technology of denaturant and methanol, which is applied in the application field of methanol denaturant and its preparation, and the production of methanol gasoline industry, which can solve the problems of low cost and other problems, and achieve the effects of environmental protection, comprehensive cost reduction and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

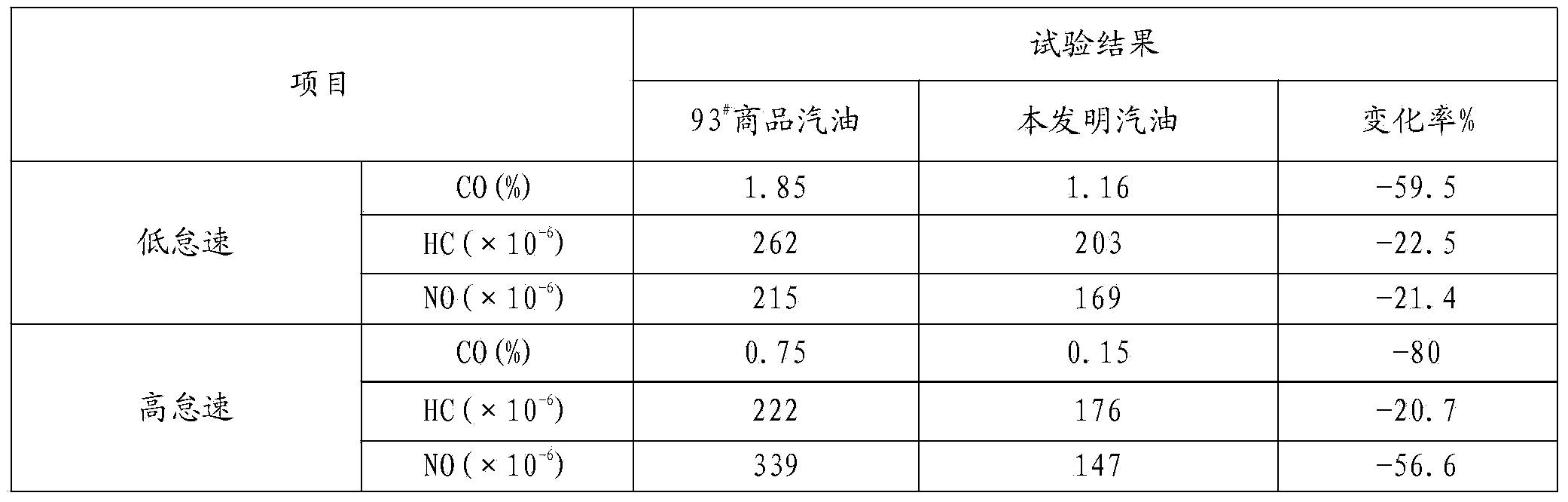

Examples

Embodiment 1

[0023] Under stirring at room temperature, 0.1 parts by volume of tolyltriazole and 0.1 parts by volume of mercaptobenzothiazole are dissolved in 3 parts by volume of dimethoxymethane to prepare solution A for subsequent use; Parts of methylcyclopentadienyl manganese tricarbonyl is dissolved in 2 parts by volume of acetone to make solution B for subsequent use; pump 10 parts by volume of methyl tert-butyl ether into the reactor, 30-50 rpm Add 2 parts by volume of methyl oleate, the solution A, the solution B, 0.5 parts by volume of isopropyl palmitate, and 1 volume part of ethanolamine, and stir for 25 minutes after all the materials are added to obtain methanol denaturant.

Embodiment 2

[0025] Under stirring at room temperature, 0.2 parts by volume of tolyltriazole and 0.05 parts by volume of mercaptobenzothiazole are dissolved in 1 part by volume of dimethoxymethane to prepare solution A for subsequent use; Parts of methylcyclopentadienyl manganese tricarbonyl is dissolved in 1 volume part of acetone to make solution B for subsequent use; 5 parts by volume of methyl tert-butyl ether is pumped into the reactor at 30-50 rpm Add 1 part by volume of methyl oleate, the solution A, the solution B, 0.2 parts by volume of isopropyl palmitate, and 0.5 parts by volume of ethanolamine, and stir for 30 minutes after adding all the materials to obtain methanol denaturant.

Embodiment 3

[0027] Under stirring at room temperature, 0.05 parts by volume of tolyltriazole and 0.2 parts by volume of mercaptobenzothiazole are dissolved in 6 parts by volume of dimethoxymethane to prepare solution A for subsequent use; Parts of methylcyclopentadienyl manganese tricarbonyl is dissolved in 4 parts by volume of acetone to make solution B for subsequent use; pump 20 parts by volume of methyl tert-butyl ether into the reactor, 30-50 rpm Add 4 parts by volume of methyl oleate, the solution A, the solution B, 1 part by volume of isopropyl palmitate, and 2 parts by volume of ethanolamine, and stir for 15 minutes after all the materials are added to obtain methanol denaturant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com