Ion film-plating device and ion film-plating method

A technology of ion coating and magnetron sputtering, applied in ion implantation coating, sputtering coating, vacuum evaporation coating, etc., can solve the problems of unstable discharge, low deposition rate, difficulty in obtaining beam current, etc., and achieve The effect of increasing the beam current density and increasing the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

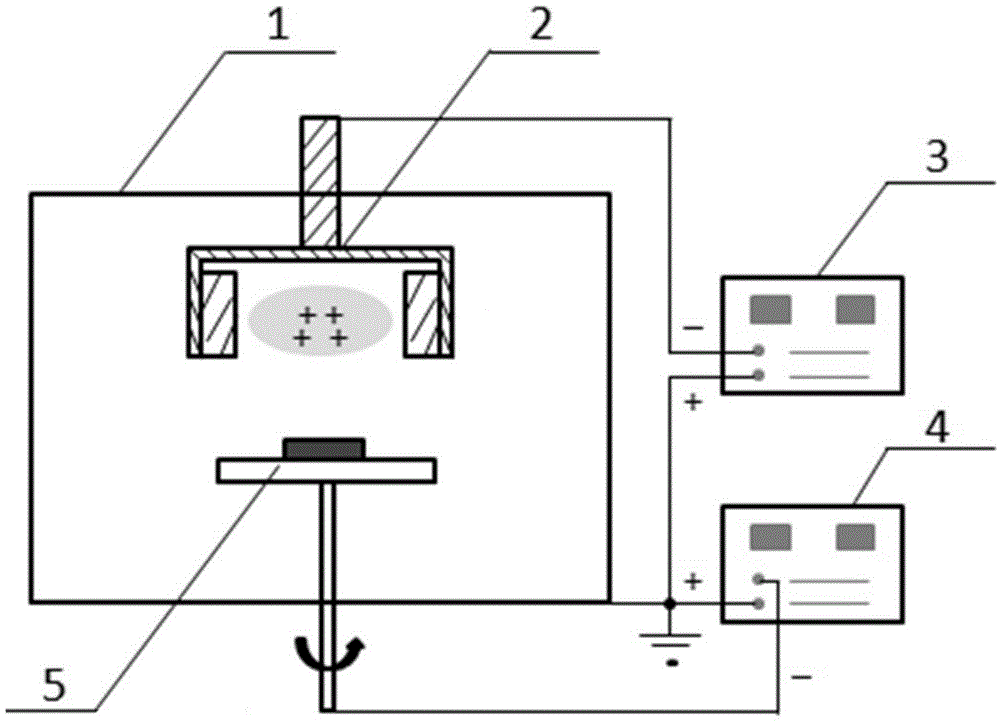

[0027] The ion plating device of this example, such as figure 1 As shown, it includes a vacuum chamber 1, a magnetron sputtering target source 2, a high-power pulse magnetron sputtering power supply 3, a bias power supply 4 and a workpiece platform 5; the vacuum chamber 1 is a closed cavity, and the magnetron sputtering target source 2 and the workpiece platform 5 are arranged in the vacuum chamber 1, and the magnetron sputtering target source 2 is located directly opposite the workpiece platform 5; the high-power pulse magnetron sputtering power supply 3 and the bias power supply 4 are arranged outside the vacuum chamber 1, and the high-power pulse The negative pole of the magnetron sputtering power supply 3 is electrically connected to the magnetron sputtering target source 2, and the positive pole is grounded. The negative pole of the bias power supply 4 is electrically connected to the workpiece platform 5, and the positive pole is grounded.

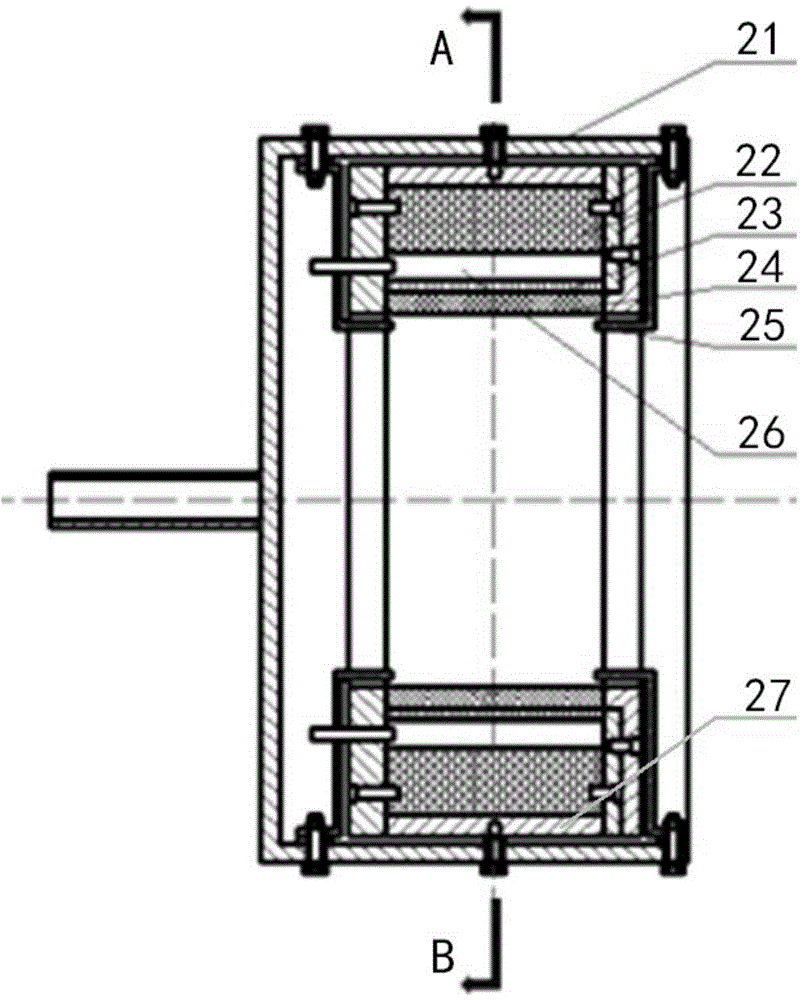

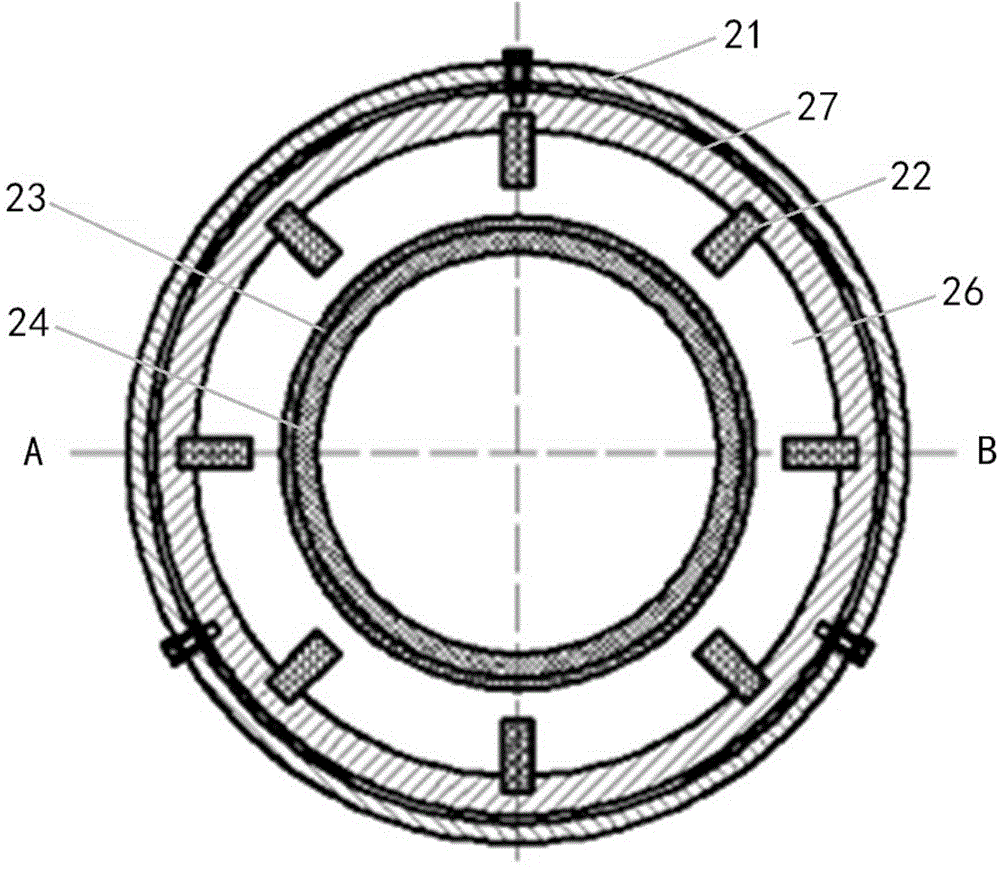

[0028] Among them, this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com