Thermal spray polymer modified asphalt waterproof adhesive layer paving structure of cement concrete bridge surface and construction method

A waterproof bonding layer, cement concrete technology, used in bridges, bridge parts, bridge construction and other directions, to achieve the effect of improving high temperature shear resistance, good durability, and strong tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

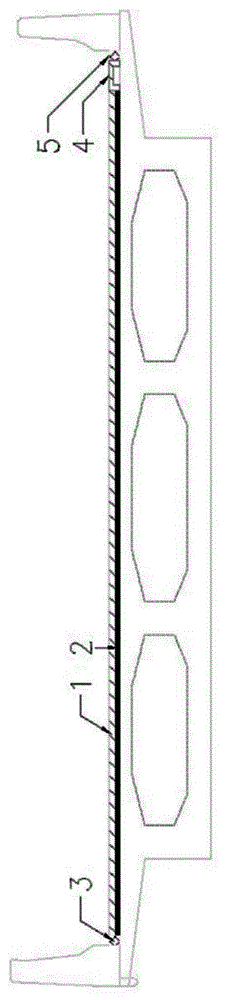

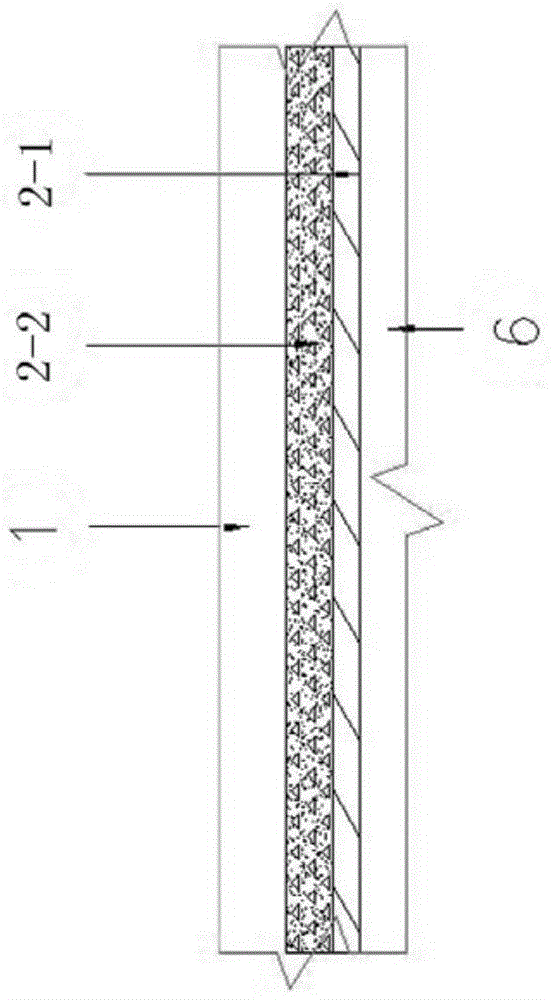

[0062] The cement concrete bridge deck thermal spray polymer modified asphalt waterproof bonding layer pavement structure of the preferred embodiment of the present invention is a pavement structure layer laid on the concrete bridge deck 6 . The pavement structure layer is composed of a waterproof bonding system arranged on the concrete bridge deck 6 and an asphalt concrete bridge deck pavement layer 1 paved on the waterproof bonding system. in,

[0063] The cement concrete bridge deck 6 is shot blasted to remove 3mm of the cement concrete bridge deck 6, or make the bridge deck concrete exposed rate of the cement concrete bridge deck 6 reach 20%, forming a dry, clean and rough interface.

[0064] The waterproof system is composed of a waterproof adhesive layer 2, an asphalt waterstop 3, a prefabricated drainage tank 4, and an anti-corrosion asphalt layer 5. Wherein said waterproof adhesive layer 2 is composed of waterproof layer 2-1 and anti-adhesive gravel layer 2-2. The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com