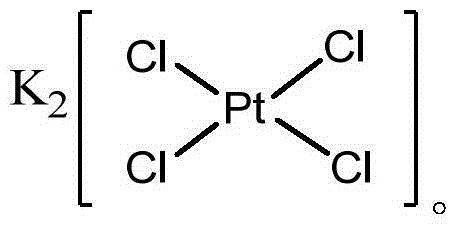

Preparation method of potassium chloroplatinite

A technology of potassium chloroplatinite and potassium chloride is applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc. Pollution and other problems, to achieve the effect of improving utilization, saving costs and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

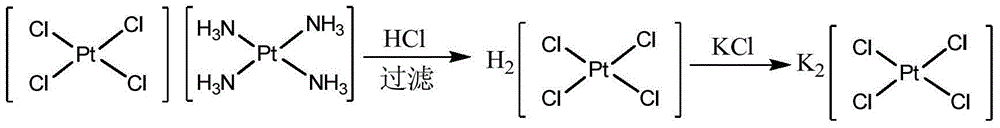

Method used

Image

Examples

Embodiment 1

[0018] Weigh 20 grams of tetraaminoplatinum and platinum tetrachloride, add 600ml of concentrated hydrochloric acid, heat and reflux for 8 hours, after cooling down, filter to remove yellow insoluble matter, and collect the filtrate. Weigh 8 grams of Potassium Chloride, add purified water, stir and dissolve, then add to the above filtrate, stir and react at room temperature for 40 minutes, boil and concentrate (temperature 98-102°C) the reaction solution under ventilated conditions until dark brown solids are produced, drop After reaching room temperature, potassium chloroplatinite crystals precipitated, filtered, and dried to obtain 11.7 g of potassium chloroplatinite (platinum content 46.75%, loss on drying 0.25%), the yield was 85%, and the effective utilization rate of platinum was 42.3%.

Embodiment 2

[0020] Weigh 35 grams of tetraaminoplatinum and platinum tetrachloride, add 1000ml of concentrated hydrochloric acid, heat and reflux for 10 hours, after cooling down, filter to remove yellow insoluble matter, and collect the filtrate. Weigh 12 grams of potassium chloride, add purified water, stir and dissolve, add to the above filtrate, stir and react at room temperature for 50 minutes, boil and concentrate (temperature 98-102°C) the reaction solution under ventilated conditions until dark brown solids are produced, and cool down At room temperature, potassium chloroplatinite crystals were precipitated, filtered, and dried to obtain 20 grams of potassium chloroplatinite (platinum content 46.85%, loss on drying 0.20%), yield 83%, and effective utilization of platinum 40.9%.

Embodiment 3

[0022] Weigh 80 grams of tetraaminoplatinum and platinum tetrachloride, add 2000ml of concentrated hydrochloric acid, heat and reflux for 15 hours, after cooling down, filter to remove yellow insoluble matter, and collect the filtrate. Weigh 26 grams of potassium chloride, add purified water, stir and dissolve, add to the above filtrate, stir and react at room temperature for 40 minutes, boil and concentrate the reaction solution under ventilated conditions (temperature 98-102°C) until a dark brown solid is produced, and cool down Potassium chloroplatinite crystals precipitated at room temperature, filtered, and dried to obtain 54.3 g of potassium chloroplatinite (46.7% platinum content, 0.22% loss on drying), with a yield of 89% and an effective utilization rate of platinum of 49.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com