Antifreezing flushing solution for cleaning oil-based drilling fluid and application

An oil-based drilling fluid and flushing fluid technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of unfavorable cementing construction, difficult preparation of flushing fluid, difficult preparation and use, etc. Effect of mixing, improving pass rate, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

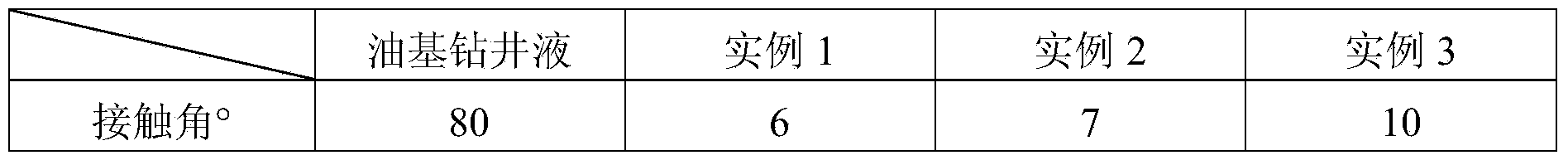

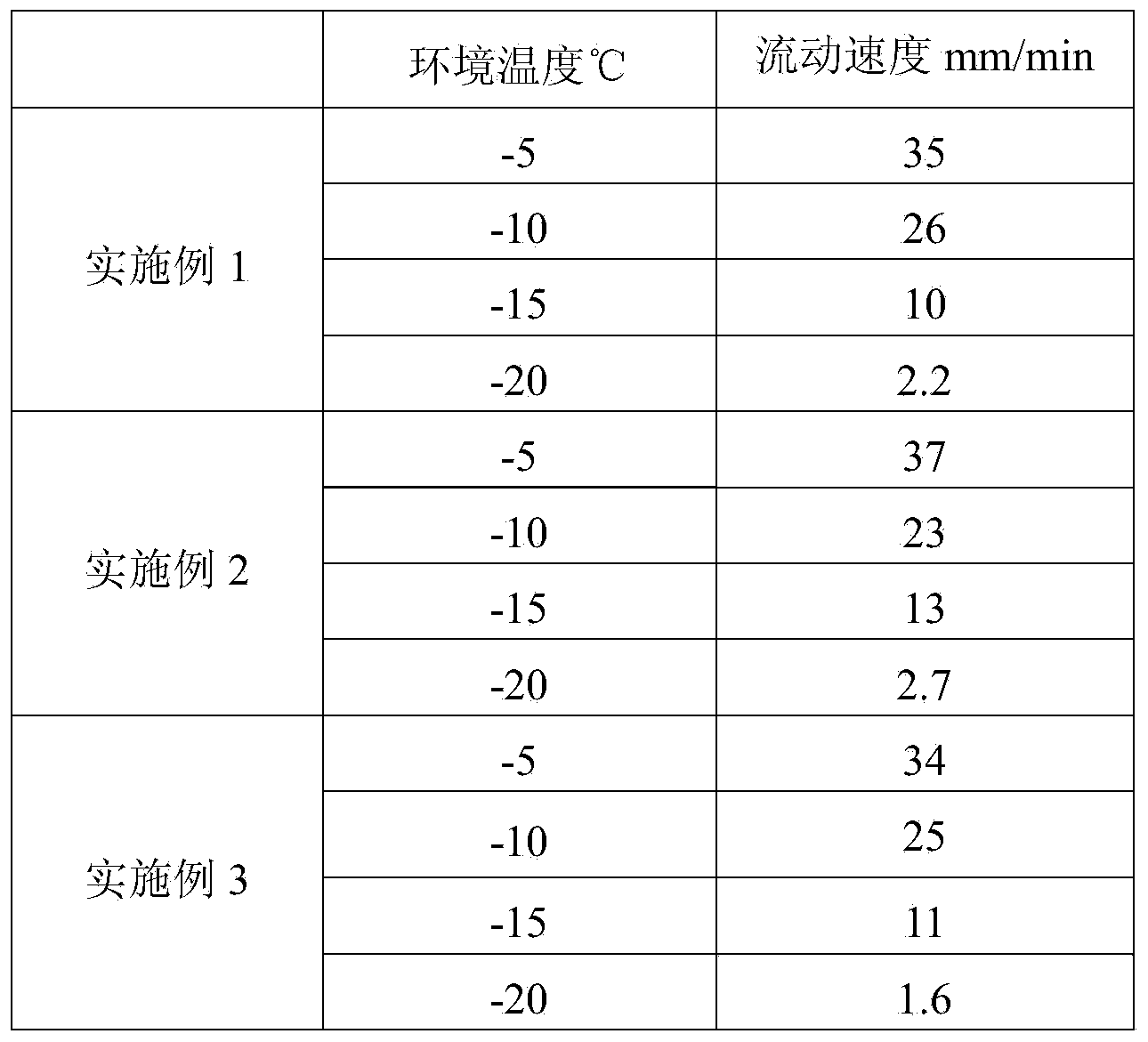

Examples

Embodiment 1

[0021] In a container (such as a three-neck flask), add 55g of fatty alcohol polyoxyethylene ether, 20 alkyl glyceryl ether sulfonate and 25g of glycerol sequentially under stirring conditions, then gradually raise the temperature to 40°C, and stir for 30 minutes to obtain A sample of the rinse solution base.

Embodiment 2

[0023] Same as Example 1, except that 45g of nonylphenol polyoxyethylene ether, 25g of alkyl glyceryl ether sulfonate, 12g of ethanol and 18g of ethylene glycol were added sequentially.

Embodiment 3

[0025] Same as Example 1, except that 40g of polyoxyethylene alkyl acyl alcohol amine, 30g of alkyl glyceryl ether sulfonate, and 30g of ethanol were sequentially added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com