Decoupling Test Device for Centrifugal Pumps

A test device, a technology for centrifugal pumps, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as inability to reduce vibration and noise, difficulty in quantitative identification of excitation sources, and inability to separate excitation sources. The connection structure is optimized to reduce the effect of vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

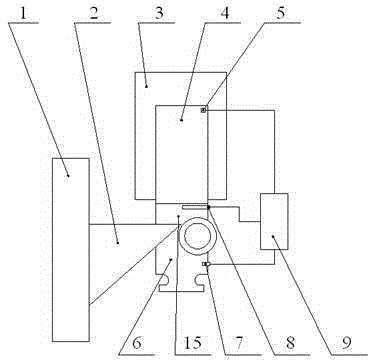

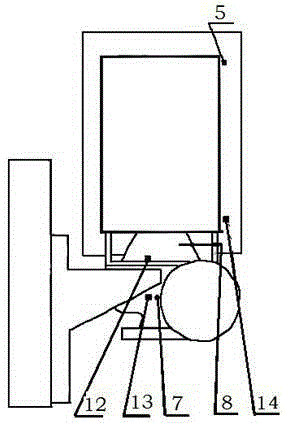

[0031] like figure 1 , As shown in 2, a decoupling test device for a centrifugal pump is mainly composed of a decoupling system, a support system, a water pump system, a drive system, and a test system.

[0032] The decoupling system consists of separate decoupling brackets 2. The support system is composed of a volute support base 1 and a motor support base 3, and the water pump system 6 is composed of impellers, volutes and other components of the centrifugal pump. The drive system is made up of drive motor 4. The test system is composed of an acceleration sensor, a wireless stress and strain sensor 15, a dynamic pressure pulsation sensor 7, an eddy current sensor 8, and a signal acquisition and data analysis device 9, etc.

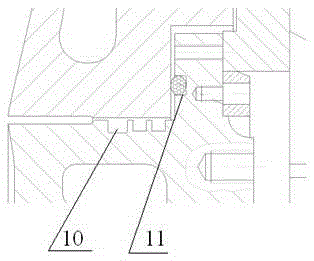

[0033] The volute is installed on the volute support base 1 by separating the decoupling bracket 2, the impeller rotor is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com