Centrifugal simulation system for freeze thawing deformation of water conveyance canal in salty-cold region

A simulation system and channel technology, applied in the field of frost heave-thaw settlement deformation characteristics, simulation test system, can solve the problem of not being able to adapt to the working environment of the centrifuge, the volume of the compressor refrigeration equipment is large, and the indoor small-scale physical model test cannot be truly reproduced Problems such as the real stress state of the canal foundation soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be made below in conjunction with drawings and embodiments.

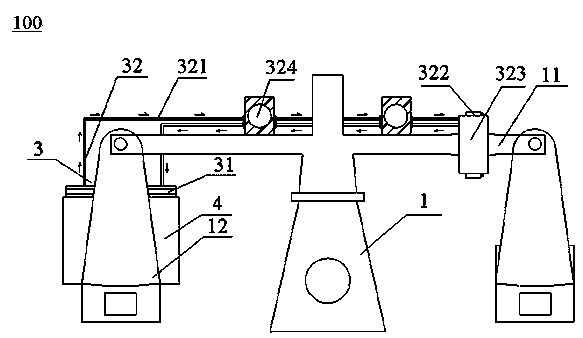

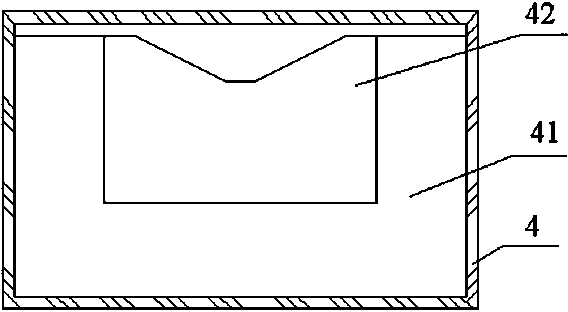

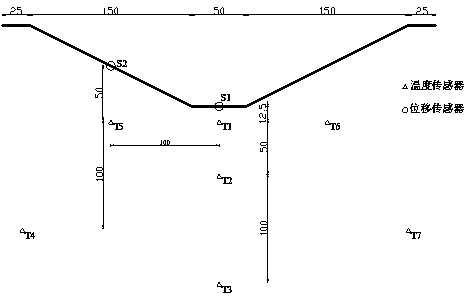

[0021] Such as figure 1 As shown, the freeze-thaw deformation centrifugal simulation system 100 of the water delivery channel in the salty cold area is composed of a centrifuge 1, a model box 4, a water circulation refrigeration device 3, a temperature controller 2 and a computer control system 5. The model box 4 consists of an outer box, an inner box The box and the interlayer filling material between the inner and outer boxes, and the channel model is set in the model box 4. The water circulation refrigerating device 3 is made up of several series-connected semiconductor cooling chips 31 and a water cooling device 32 , and the water cooling device 32 includes a water pipe 321 , a water pump 322 , an air-cooled condenser 324 and a water tank 323 . The temperature controller (not shown in the figure) includes a temperature controller and a temperature sensor, which are used for setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com