Working fluid composition for refrigerator, refrigeration oil, and method for producing same

一种工作流体、冷冻机油的技术,应用在润滑组合物、化学仪器和方法、石油工业等方向,能够解决温室效果大等问题,达到低吸湿性、综合性能优异、优异稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0035] [1st Embodiment: Refrigeration Oil and its Manufacturing Method]

[0036] The refrigerating machine oil according to the first embodiment of the present invention is used together with a hydrocarbon refrigerant having 2 to 4 carbon atoms, and contains refrigerating machine oil whose kinematic viscosity at 40°C is 2 to 12 mm 2 / s, the flash point is 120°C or higher, and the %C in the n-d-M ring analysis is contained in the mass ratio of mineral oil / alkylbenzene=85 / 15 to 15 / 85 N is 20 to 60, the pour point is -15°C or less, and the kinematic viscosity at 40°C is 1.5 to 15mm 2 / s of the aforementioned mineral oil, and the aforementioned alkyl benzene.

[0037] Further, the method for producing a refrigerating machine oil for a hydrocarbon refrigerant having 2 to 4 carbon atoms according to the first embodiment of the present invention includes a step of obtaining refrigerating machine oil whose temperature of the refrigerating machine oil is at a temperature of 40° C. Th...

no. 2 Embodiment approach

[0066] [Second Embodiment: Working Fluid Composition for Refrigerator]

[0067] The working fluid composition for refrigerators according to the second embodiment of the present invention contains refrigerator oil having a kinematic viscosity of 2 to 12 mm at 40° C. and a hydrocarbon refrigerant having 2 to 4 carbon atoms. 2 / s, the flash point is 120°C or higher, and the mass ratio of mineral oil / alkylbenzene=85 / 15 to 15 / 85 contains %C in n-d-M ring analysis N is 20 to 60, the pour point is -15°C or less, and the kinematic viscosity at 40°C is 1.5 to 15mm 2 / s of the aforementioned mineral oil, and the aforementioned alkyl benzene. It should be noted that the refrigerating machine oil contained in the working fluid composition for a refrigerator according to the present embodiment is the same as the refrigerating machine oil described in the above-mentioned first embodiment, and therefore, the overlapping description is omitted here.

[0068] Specific examples of the hydroc...

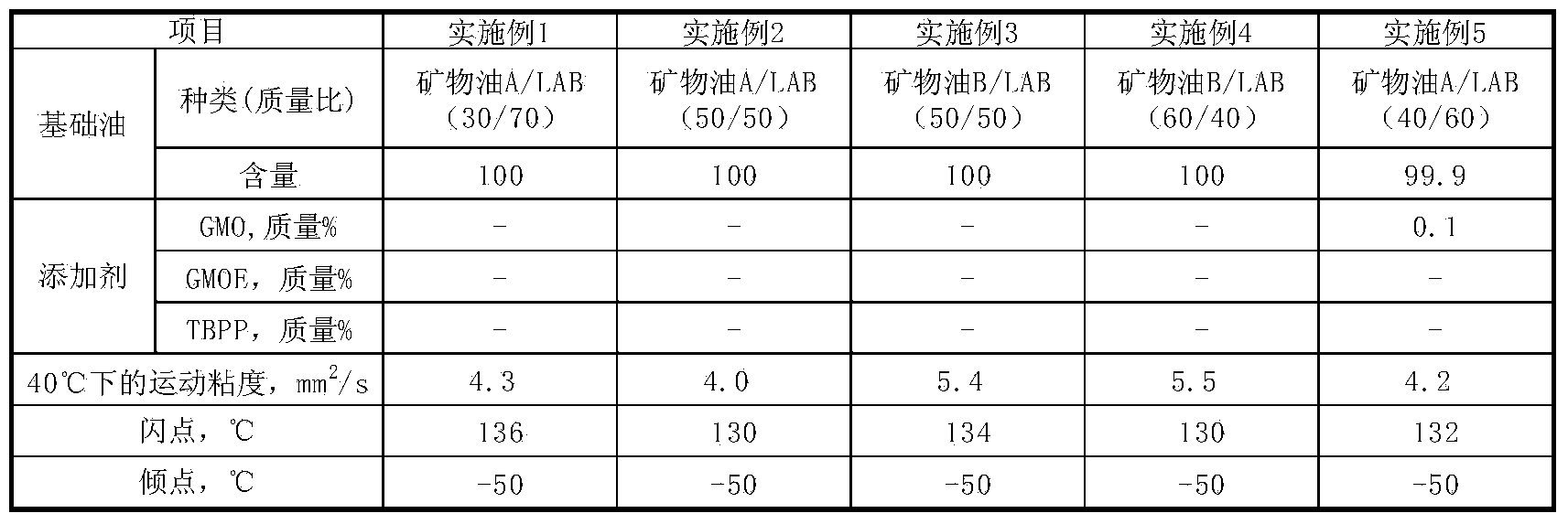

Embodiment 1

[0073] The kinematic viscosity at 40°C is 3.4mm 2 / s, flash point 108°C, %C under n-d-M ring analysis N Mineral oil (VG3 base oil manufactured by Yoshikun Nippon Oil & Energy Co., Ltd.) with a pour point of 40 and a pour point of -50°C or lower. Hereinafter, referred to as "mineral oil A"), and the kinematic viscosity at 40°C is 4.5 mm 2 / s, Alkylbenzene with a flash point of 158°C (manufactured by Yoshikun Nippon Oil & Energy Co., Ltd., straight-chain alkylbenzene, referred to as "LAB") was mixed in a mass ratio of mineral oil A / LAB=30 / 70 , resulting in a kinematic viscosity of 4.1mm at 40°C 2 Refrigeration oil with a flash point of 136°C and a pour point of -50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com