Technology for bionic cultivation of wild ganoderma lucidum in bamboo forest

A technology imitating wild and Ganoderma lucidum, applied in fertilizer mixtures, horticulture, botanical equipment and methods, etc., can solve problems such as differences in drug value, and achieve the effects of abundant rainfall, increased comprehensive utilization, and good growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

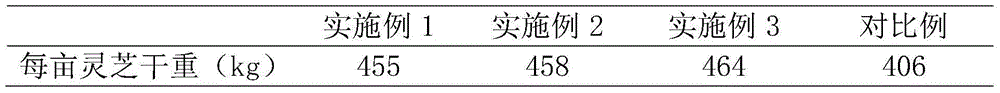

Examples

Embodiment 1

[0056] A bamboo grove imitation wild ganoderma cultivation technique, comprises the steps:

[0057] 1) Cultivation environment: choose the bamboo forest land at the foot of Maoer Mountain in Xing’an, Guilin, with an altitude of 600-900m, the relative air humidity is between 80-90%, and the temperature is 8-35°C;

[0058] Cultivation time: September to next March;

[0059] 2) Basswood fungus management:

[0060] a. The preparation of cultivation materials: miscellaneous wood chips 46%, bagasse 42%, corn flour 10%, soybean flour 1%, gypsum powder 1%;

[0061] B, the branch that prepares the raw material cultivation Ganoderma lucidum is cut into length 50cm, the basswood of diameter 8cm, is lighted all around, and section is smooth, and branch is selected from the broad-leaved tree except pine fir, eucalyptus, camphor tree;

[0062] c. Sterilization in bags: After the basswood is dried, put it into a polyethylene plastic bag, cover the basswood with a layer of mixed planting ma...

Embodiment 2

[0073] A bamboo grove imitation wild ganoderma cultivation technique, comprises the steps:

[0074] 1) Cultivation environment: choose bamboo forest land at an altitude of 600-900m in the bamboo forest of Sanjie Town, Lingchuan, Guilin, with relative air humidity between 80-90%, and temperature of 8-35°C;

[0075] Cultivation time: September to next March;

[0076] 2) Basswood fungus management:

[0077] a. The preparation of cultivation materials: miscellaneous wood chips 46%, bagasse 42%, corn flour 10%, soybean flour 1%, gypsum powder 1%;

[0078] B, the branch of preparation material cultivation Ganoderma lucidum is cut into length 80cm, the basswood of diameter 30cm, is lighted all around, and section is smooth, and branch is selected from the broad-leaved tree except pine fir, eucalyptus, camphor tree;

[0079] c. Sterilization in bags: After the basswood is dried, put it into a polyethylene plastic bag, cover the basswood with a layer of mixed planting material, tie t...

Embodiment 3

[0090] A bamboo grove imitation wild ganoderma cultivation technique, comprises the steps:

[0091] 1) Cultivation environment: select the bamboo forest land at an altitude of 600-900m in the bamboo forest of Chanjiang Natural Village, Yong'an Village Committee, Rongjiang Town, Xing'an, Guilin, with a relative air humidity of 80-90% and a temperature of 8-35°C;

[0092] Cultivation time: September to next March;

[0093] 2) Basswood fungus management:

[0094] a. The preparation of cultivation materials: miscellaneous wood chips 46%, bagasse 42%, corn flour 10%, soybean flour 1%, gypsum powder 1%;

[0095] B, the branch that prepares the material cultivation Ganoderma lucidum is cut long 60cm, the basswood of diameter 20cm, all around is lighted, and section is smooth, and branch is selected from the broad-leaved tree except pine fir, eucalyptus, camphor tree;

[0096] c. Sterilization in bags: After the basswood is dried, put it into a polyethylene plastic bag, cover the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com