Wall surface wooden furniture moisture-resistant and termite-resistant structure

A wooden furniture, anti-termite technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., to achieve the effects of preventing termites, high bonding strength, and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

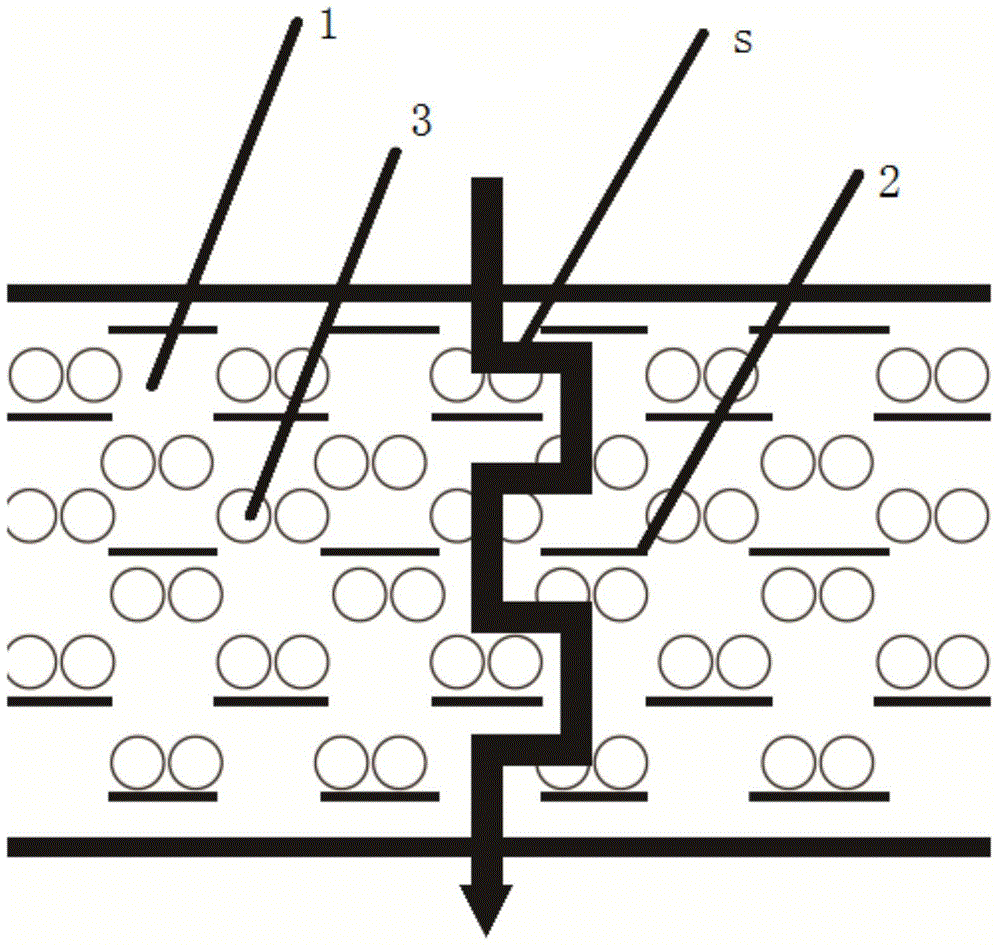

[0057] A large amount of wooden furniture is used for the wall decoration of a villa, such as solid wood door frames, TV background walls, cloakrooms, cabinets, etc. The base layer of the fixed wooden furniture on the wall is painted with anti-termite inorganic scale water-based epoxy resin paint to form a moisture-proof Anti-termite coating, and then use this coating to paint the entire exposed bottom surface of the wooden furniture on the ground floor (that is, the side close to the wall), and carry out a moisture-proof and termite-proof treatment on the weakest link in the wooden decoration structure. Moisture-resistant membrane construction.

[0058] The moisture-proof structure of the interior wall of the building in this embodiment is composed of a base material layer composed of concrete or cement mortar, a moisture-proof and termite-proof coating, and wooden furniture attached to the wall. The specific formation process is as follows:

[0059] After cleaning, smoothing...

Embodiment 2

[0071] For the wall decoration of an apartment, a solid wood door frame of a certain brand was selected as the bathroom and room decoration material. During the production and installation, the base material layer was first leveled with cement mortar, and then painted with an anti-termite inorganic scale water-based epoxy resin coating to form a moisture-proof and anti-corrosion Termite surface layer, and then paint 1-2 coats on the bottom lining of the wooden door frame (that is, the wall surface) for moisture-proof and termite-proof treatment.

[0072] The moisture-proof structure of the wooden floor in the present embodiment is made of substrate layer, moisture-proof and termite-proof surface layer and wooden furniture sticking wall surface, and concrete formation process is as follows:

[0073] After cleaning, smoothing and drying the surface of the substrate layer, form a moisture-proof and termite-proof surface layer on the substrate layer: first coat the substrate layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com