Counter-force plate loading hole construction method and device

A construction method and loading hole technology, which are applied to building components, building structures, earthquake-proof and other directions, can solve the problems of large consumption of manpower and material resources, high accuracy of loading holes, and difficulty in controlling the accuracy of pouring and finishing surface flatness, so as to improve the The effect of positioning accuracy and work efficiency, reducing labor intensity and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

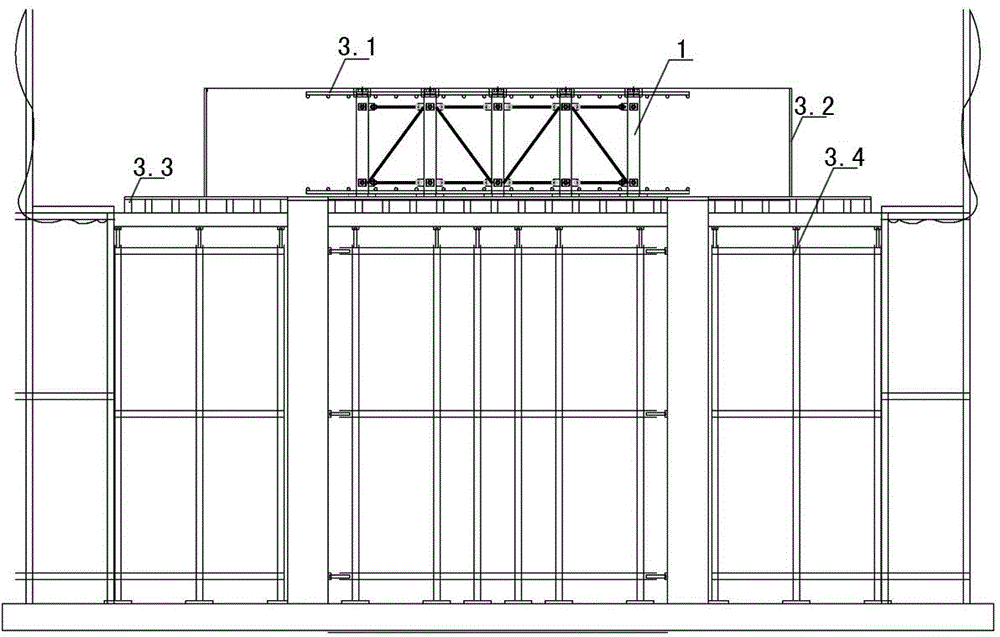

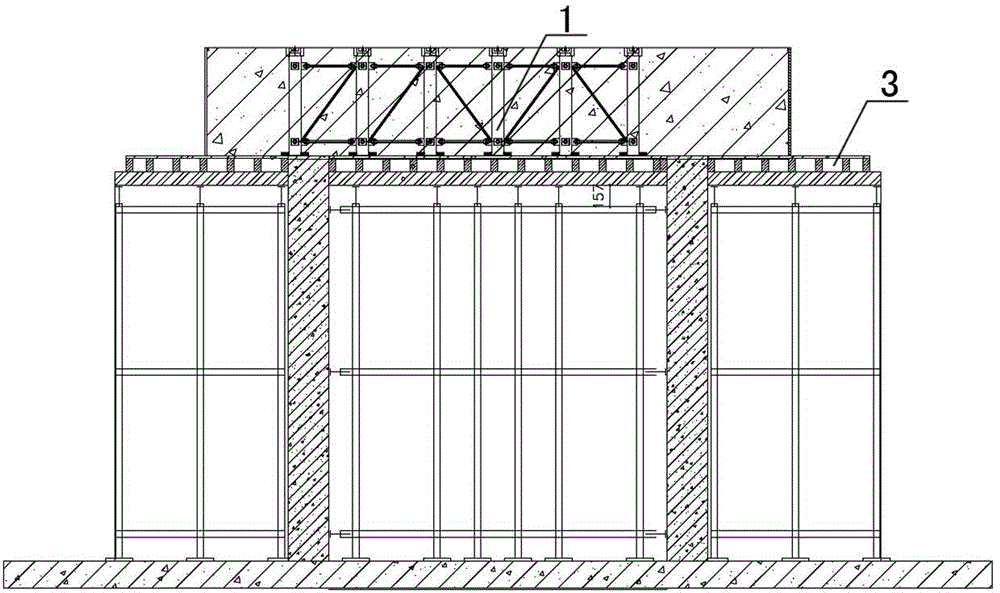

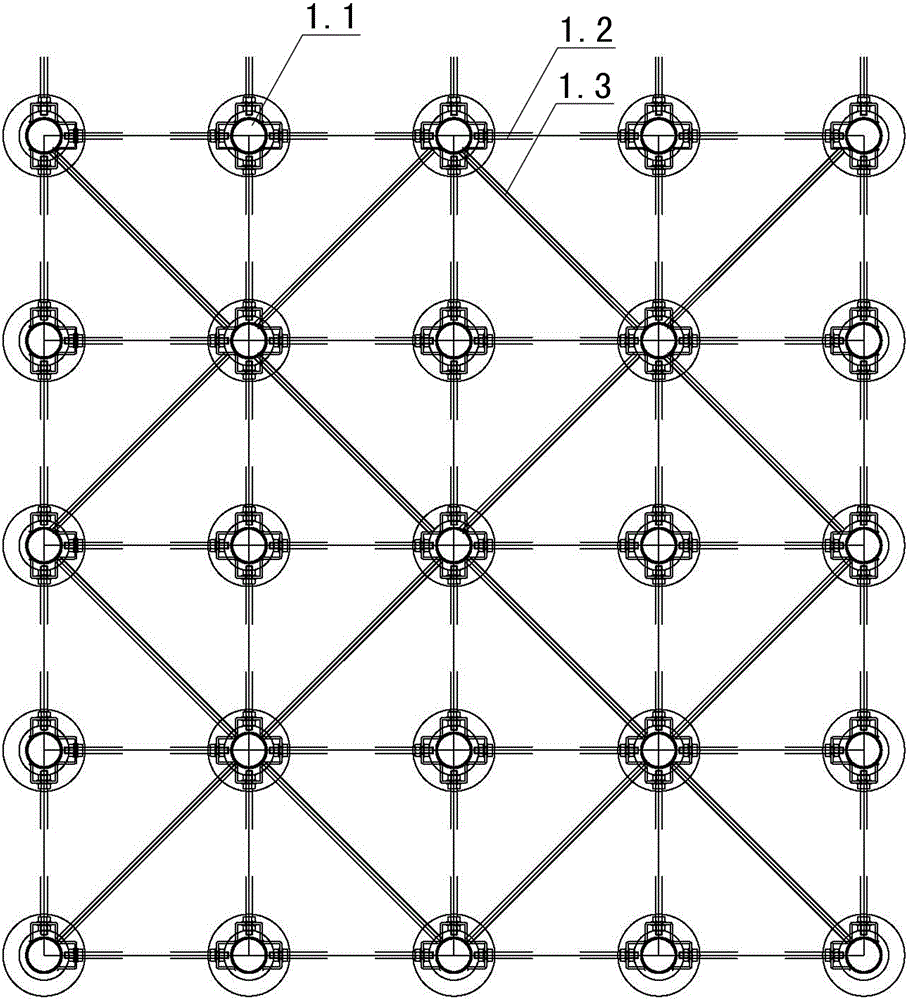

[0059] see figure 1 , figure 2 Shown: The counter force plate is 140 meters long, 36 meters wide, and has an area of about 4,000 square meters; the plate thickness is 800mm, the elevation of the plate surface is ±0.00, and the elevation of the plate bottom is -0.8m; the counter force plate is finished fair-faced concrete, and the concrete strength is C40. Concrete is painted as it is beaten, and the surface is finished with a wear-resistant layer of primary color at one time; the surface is protected by curing agent; the reaction plate is equipped with loading holes with a diameter of 80mm and a length of 800mm, and the spacing of the loading holes is 500mm, which is evenly arranged.

[0060] The foundation of the reaction slab is a flat pile-raft foundation; the length of the piles under the reaction slab is 17.3m, the diameter of the pile is 600mm, and 272; the concrete strength grade is C35; there is a short wall between the reaction slab and the foundation, the wall thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com