Flow guiding shell of submerged pump

A diversion shell and submersible pump technology, which is applied to pumps, pump components, non-variable pumps, etc., can solve the problems of increased water resistance in the water flow channel, complex shape of the diversion shell, and reduced efficiency of the submersible pump. Reliability, abundant raw materials, and the effect of improving water intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

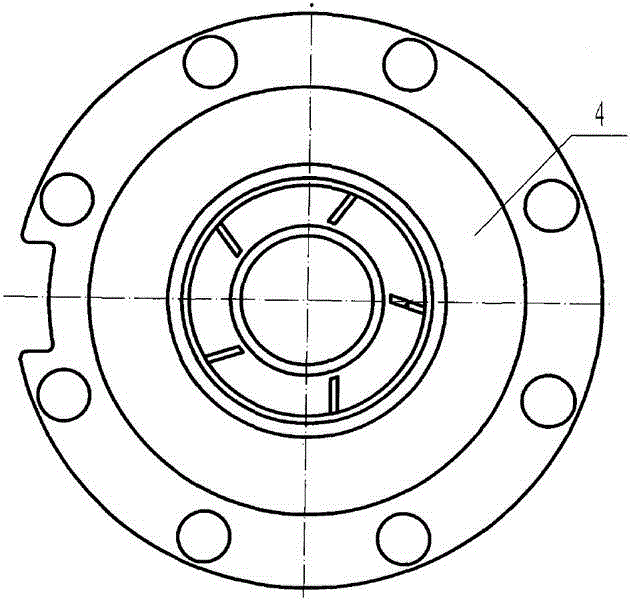

[0014] The diversion casing of the submersible pump in this embodiment is as follows: figure 1 and figure 2 As shown, it includes a shell and a bearing frame 2. The upper part of the shell is flange-shaped, and the lower part of the shell is provided with a boss 4. The bearing frame 2 is located below the inside of the shell; the shell includes a ceramic tube 1, a rubber layer, and 3 and metal layer 5. Resin glue is coated between the rubber layer 3 , the ceramic tube 1 and the metal layer 5 , and the resin glue can be epoxy resin glue or the like.

[0015] This embodiment utilizes the advantages that the surface of the ceramic tube 1 of the shell is smooth and easy to manufacture, and avoids the shortcomings of the rough surface of the guide shell made of cast iron, which is difficult to finish, thereby reducing the resistance of the water flow in the pipeline and improving the performance of the submersible pump. Inlet efficiency. A rubber layer 3 is coated on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com