Spiral flat pipe type buried pipe

A technology of buried pipes and spirals, applied in the field of ground source heat pumps, can solve the problems of fluid flow not easily turbulent, low utilization rate of geothermal energy, limited contact surface, etc., to thin the flow boundary layer and reduce heat transfer heat The effect of resistance and flow velocity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

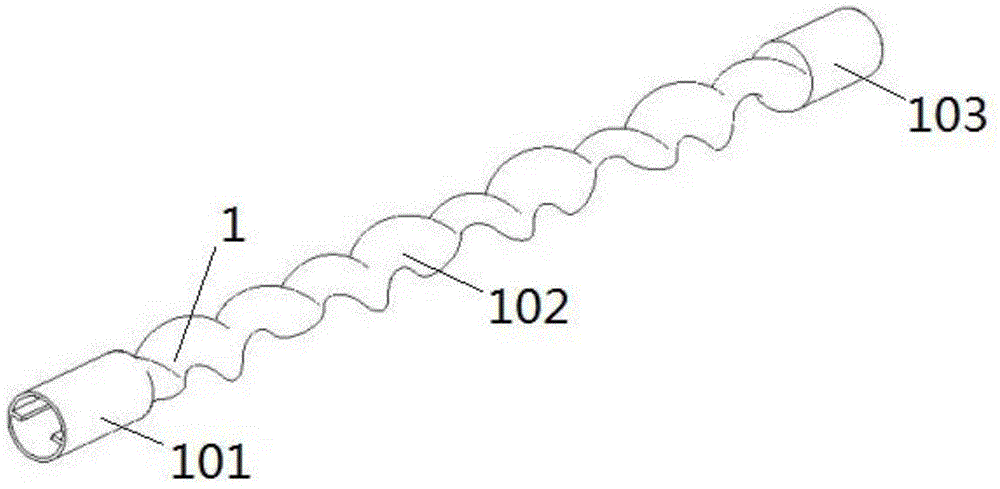

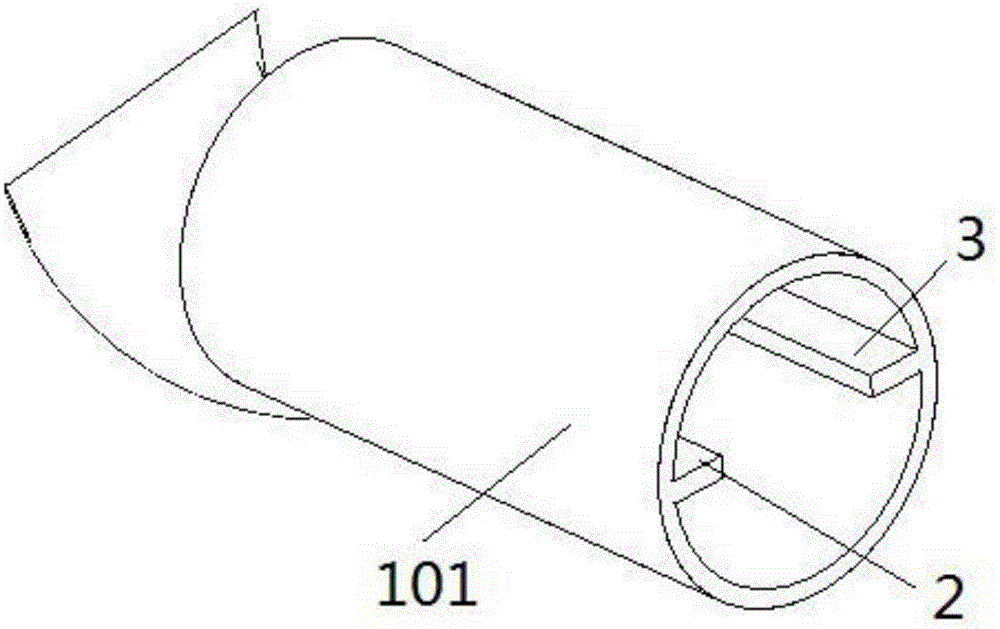

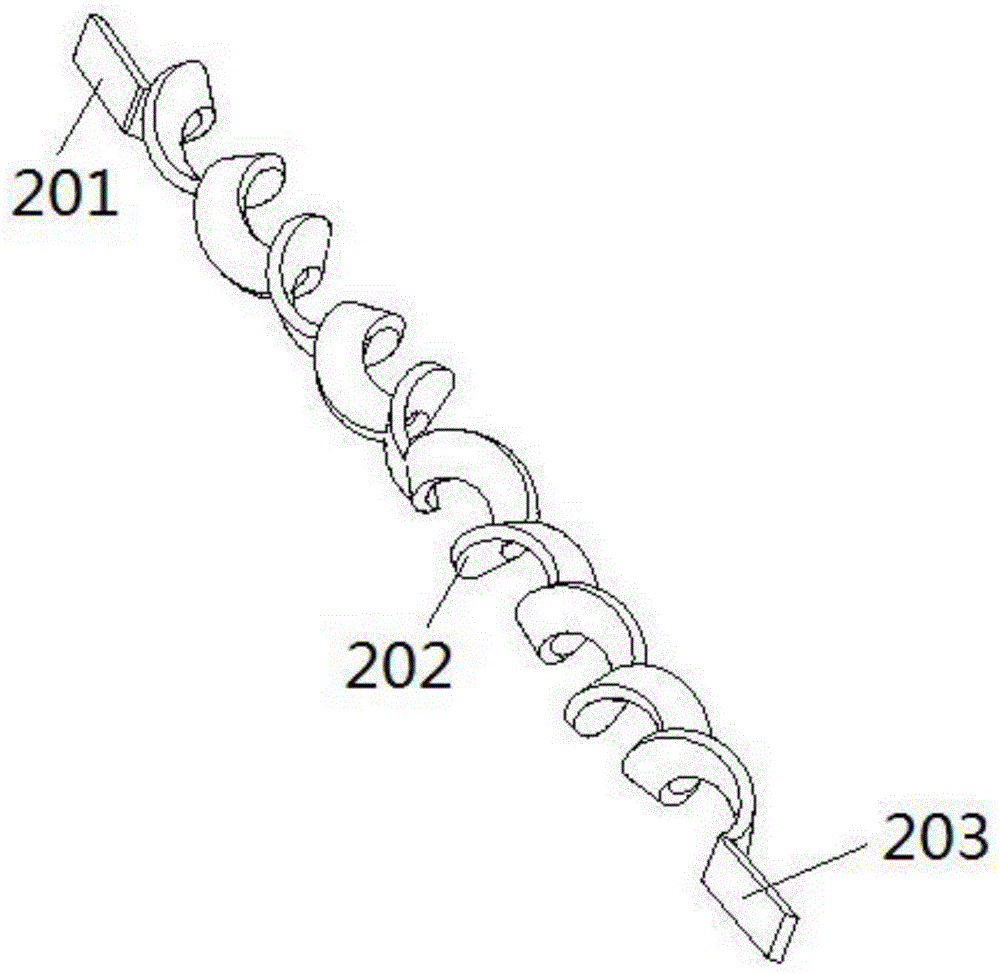

[0025] like figure 1 , figure 2 , image 3 As shown, a spiral flat pipe buried pipe includes a buried pipe body 1, the middle part of the buried pipe body 1 along the length direction is a curved pipe section 102, and one end of the buried pipe body 1 is an imported hot-melt The connecting pipe 101, the other end of the buried pipe body 1 is the outlet hot-melt connecting pipe 103, the inlet hot-melt connecting pipe 101, and the outlet hot-melt connecting pipe 103 are straight pipes with a circular cross section, and the curved pipe section 102 is a spiral rotation Shape, the spiral center line of the curved pipe section 102 coincides with the axes of the inlet hot-melt connecting pipe 101 and the outlet hot-melt connecting pipe 103, the cross-section of the curved pipe section 102 is elliptical, and the curved pipe section 102 is formed by winding a cylindrical helix in an elliptical ring; bending The enhanced heat transfer of the pipe section 102 is embodied in the follow...

Embodiment 2

[0029] With embodiment 1, the difference is, as Figure 4 , Figure 5 As shown, the number of heat exchange ribs is 3, and the cross section of the heat exchange ribs is trapezoidal. The heat exchange ribs 4 , the first heat exchange ribs 2 , the second heat exchange ribs 3 and the third heat exchange ribs 4 have the same structure. The trapezoidal cross-section design can further increase the contact area between the fluid and the pipe, which is more conducive to the heat transfer of the pipe. The number of heat exchange ribs is also increased to three, which can better enhance the turbulent flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com