Hall-effect large-diameter pipeline flowmeter

A large-caliber pipeline and Hall effect technology, which is applied in the direction of detecting fluid flow and volume/mass flow generated by electromagnetic effects with electromagnetic flowmeters, can solve the problems of inability to measure flow accurately, inconvenient installation and maintenance, and difficult manufacturing. Achieve good social and economic benefits, use less materials, and lower costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

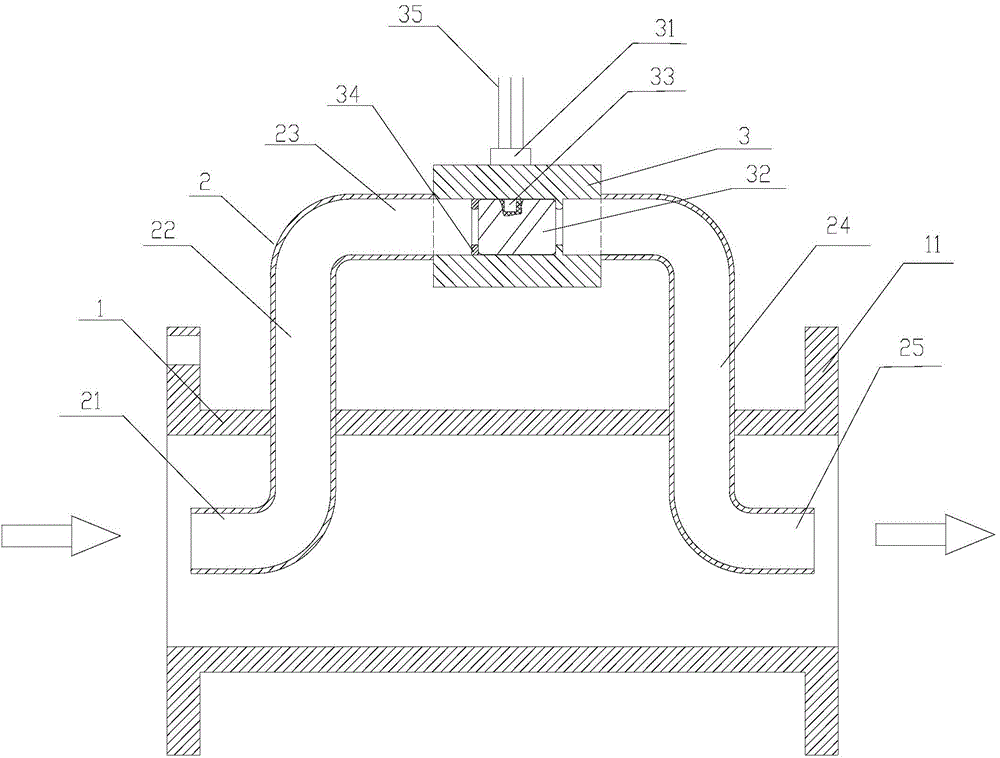

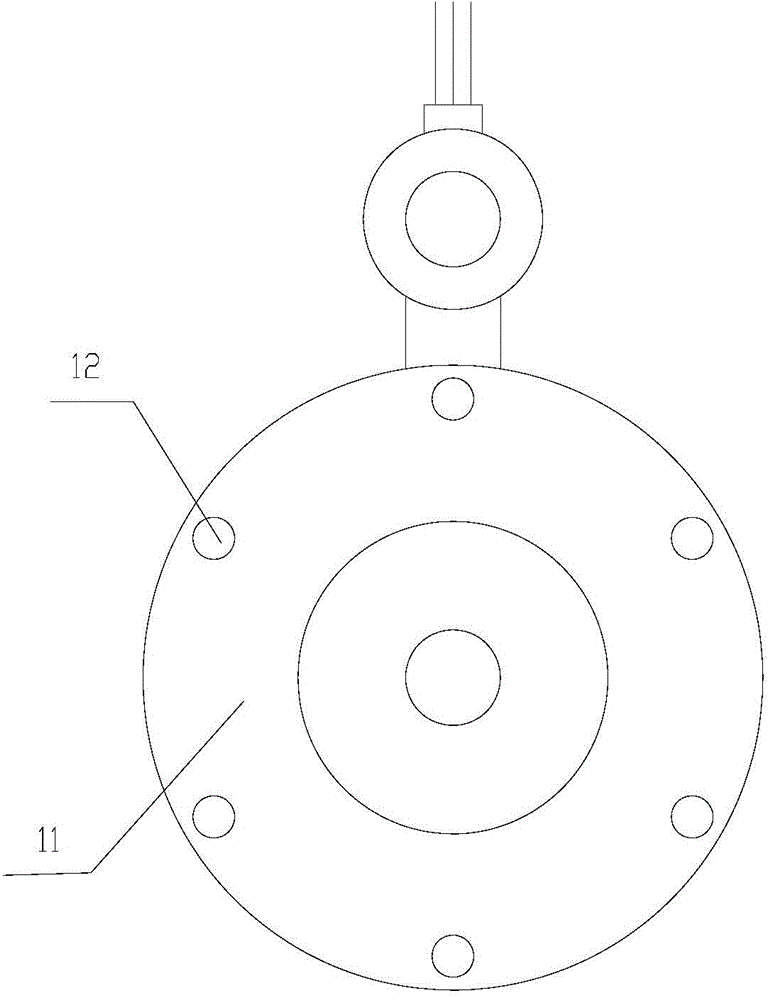

[0029] Such as figure 1 As shown, the two ends of the small-diameter branch pipe 2 are embedded in the large-diameter pipe 1, and the small-diameter pipe 2 includes a horizontal inlet port 21, an ascending section 22, a horizontal section 23, a descending section 24, and a horizontal outlet port 25; the horizontal inlet port 21, The horizontal section 23 and the horizontal outlet end 25 are parallel to the large-diameter pipe 1, and the ascending section 22 and the descending section 23 are perpendicular to the large-diameter pipe 1; The flow direction of the caliber tube 1 is the same; figure 2 As shown, the two ports of the large-diameter pipe 1 are provided with a connecting edge 11, and the connecting edge 11 is provided with a bolt hole 12, which can be connected with the pipe to be measured through a flange. figure 1The direction indicated by the middle arrow is the direction of fluid flow, which enters from the left end of the large-diameter pipe 1 and flows out from ...

Embodiment 2

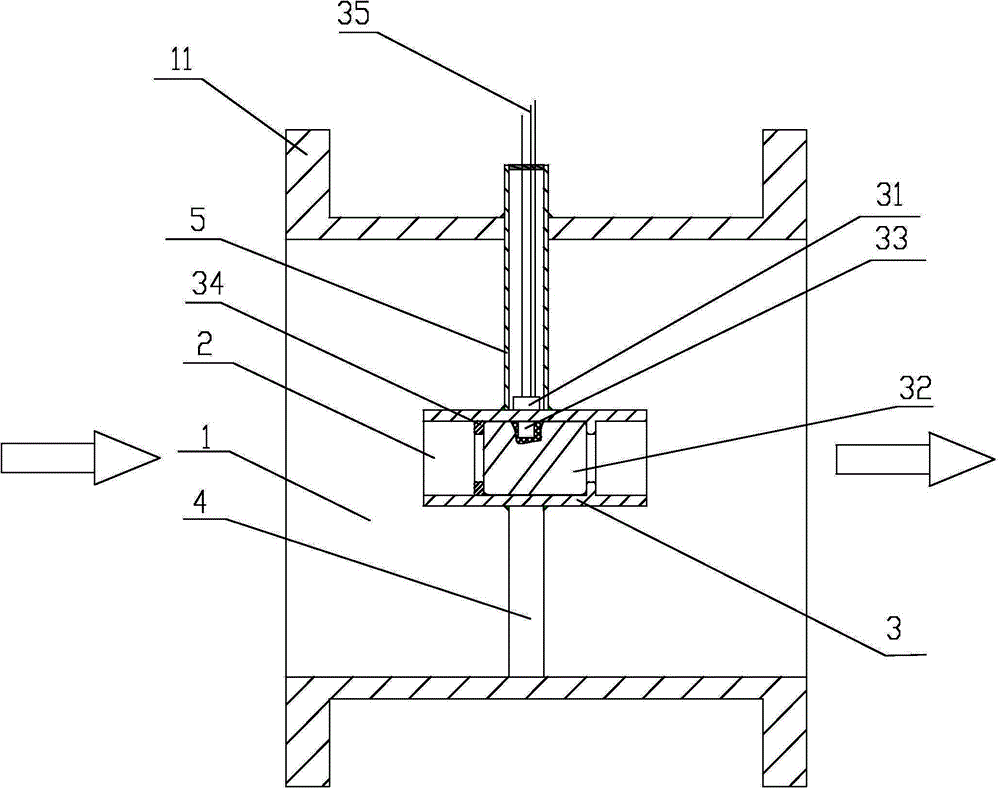

[0033] Such as image 3 As shown, the small-diameter branch pipe 2 is completely arranged in the large-diameter pipe 1, the bottom of the small-diameter branch pipe 2 is fixedly connected with the lower inner wall of the large-diameter pipe 1 through the lower support rod 4, and the top of the small-diameter branch pipe 2 is connected to one end of the upper branch pipe 5. Fixedly connected, the other end of the upper branch pipe 5 passes through the upper inner wall of the large-diameter pipe 1. The top connection between the upper branch pipe 5 and the small-diameter branch pipe 2, and the place where the upper branch pipe 5 passes through the outer wall of the large-diameter pipe 1 are all waterproofed and sealed. The two ports of the large-diameter pipe 1 are provided with connecting edges 11, and the connecting edges 11 are provided with bolt holes (the figure is shown, and can refer to figure 2 ), which can be connected with the pipe to be measured through the flange. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com