Permeable eyeball cover

An eye cover, transparent technology, used in glasses/goggles, optics, instruments, etc., can solve the problems of eye hypoxia, poor permeability, diseases, etc., and achieve the effect of increasing permeability and easy flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

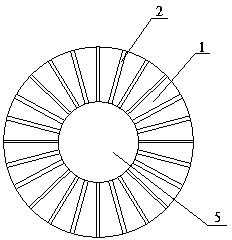

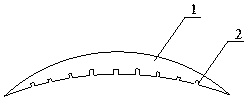

[0033] Such as figure 1 As shown, the see-through eyeball cover of this embodiment includes a spherical crown cover body 1 that is attached to the surface of the eyeball and coincides with the curved surface of the eyeball. The cover body 1 is produced, preserved, stored, and cleaned according to the method of contact lenses or cosmetic contact lenses. , soaking, wearing, and taking off, and should meet or be compatible with the requirements of ophthalmic bandages, medicine, surgery, treatment, health care, hygiene and other industries. The average thickness of the cover body 1 is 1mm~1.5mm.

[0034] The side of the cover body 1 close to the eyeball is provided with a number of radially arranged micro-channels 2, the depth of the micro-channels 2 is 3000um~0.1mm, and the depth of the micro-channels 2 is smaller than the thickness of the cover body 1 (in order to maintain the integrity of the cover body sex), the width of the micro-channel 2 is 100um~2000um. Such as figure 1...

Embodiment 2

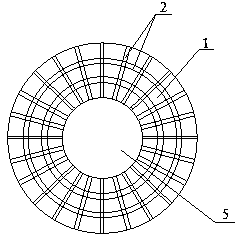

[0036] Such as image 3As shown, the see-through eyeball cover of this embodiment includes a spherical crown cover body 1 that is attached to the surface of the eyeball and coincides with the curved surface of the eyeball. The cover body 1 is produced, preserved, stored, and cleaned according to the method of contact lenses or cosmetic contact lenses. , soaking, wearing, and taking off, and should meet or be compatible with the requirements of ophthalmic bandages, medicine, surgery, treatment, health care, hygiene and other industries. The average thickness of the cover body 1 is 0.8mm~1.2mm.

[0037] The surface of the cover body 1 close to the eyeball is provided with a number of radially arranged microchannels 2. At the same time, the surface of the cover body 1 close to the eyeball is also provided with annularly distributed microchannels 2. The radially arranged microchannels 2 and the micro-channels 2 distributed in a ring form a micro-channel network. The center or of...

Embodiment 3

[0040] Such as Figure 4 , Figure 5 As shown, the see-through eyeball cover of this embodiment includes a cover body 1 that is attached to the surface of the eyeball and coincides with the curved surface of the eyeball. 1 has a ring structure as a whole, and the width between the inner ring and the outer ring of the cover body 1 is 5-20mm. The mask body 1 is produced, preserved, stored, cleaned, soaked, worn, and removed in the same way as the contact lenses, and should meet or be compatible with the requirements of ophthalmic bandages, medicine, surgery, treatment, health care, hygiene and other industries. The average thickness of the cover body 1 is 1.3mm~1.8mm.

[0041] The cover body 1 is provided with a number of parallel or staggered microchannels 2 close to the surface of the eyeball. These microchannels 2 form a microchannel network, and the mesh size of the formed microchannel network is 5-2000 mesh.

[0042] The depth of the micro channel 2 is 5000um~0.01mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com