Mud-loving grouting reinforcement material and grouting process

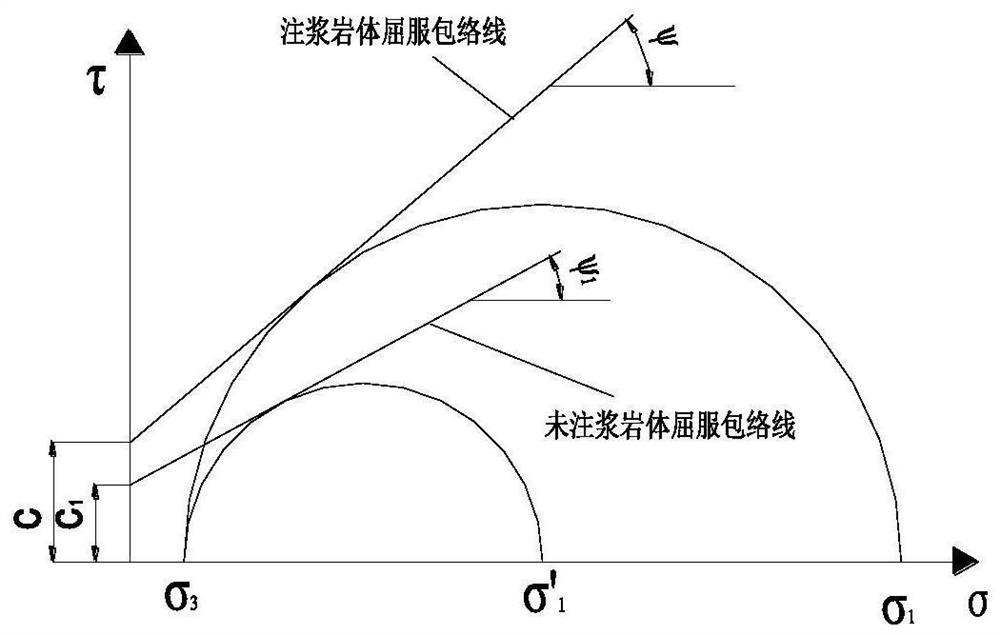

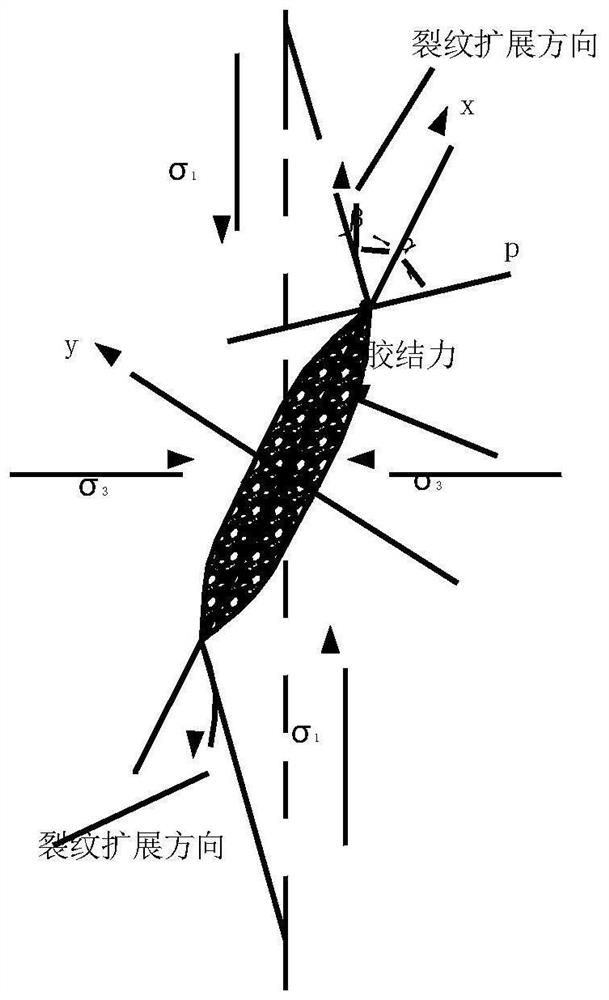

A technology of grouting reinforcement and material composition, which is applied in the direction of wellbore lining, tunnel lining, underground chamber, etc., can solve the problems that expansive rock formations are difficult to play the role of grouting reinforcement, the diffusion radius is small, and pollute the environment, so as to increase the resistance The ability of external shear damage, large penetration radius, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] A mud-friendly grouting reinforcement material, the composition of the grouting reinforcement material is: 45%-55% of calcium oxide, 5%-15% of sulfur trioxide, 15%-25% of silicon dioxide, Aluminum oxide 5%-15%, calcium silicate 1%-5%, calcium sulfate 3%-10%. Preferably, in terms of weight percentage, the composition of the grouting reinforcement material includes: calcium oxide 51-53%, sulfur trioxide 9-11%, silicon dioxide 19-21%, aluminum oxide 8-10%, silicic acid Calcium 2-4%, calcium sulfate 4-6%. Preferably, the proportion of components other than the above-mentioned material components does not exceed 2%.

[0043] Through the combination of the above components, it is ensured that the bonding strength of the mud-friendly grouting reinforcement material with mudstone at the same concentration is 1.5 to 2 times that of P42. The average compressive strength is greater than 10.0MPa, the average 7-day flexural strength is greater than 6.0MPa, and the average compress...

example 1

[0065] A mud-friendly grouting reinforcement material, the composition of the grouting reinforcement material is: 52% calcium oxide, 10% sulfur trioxide, 20% silicon dioxide, 9% aluminum trioxide, calcium silicate 3%, Calcium Sulfate 5%, and the rest of the ingredients add up to 1%.

example 2

[0067] A mud-friendly grouting reinforcement material, the composition of the grouting reinforcement material is: calcium oxide 51%, sulfur trioxide 11%, silicon dioxide 19%, aluminum oxide 10%, calcium silicate 2%, Calcium Sulfate 6%, and the rest of the ingredients add up to 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com