Epoxy glue for mini LED and preparation method thereof

A technology of epoxy glue and epoxy ring, applied in the direction of epoxy resin glue, adhesive, non-polymer adhesive additives, etc., can solve the problems of high curing shrinkage, difficult leveling and defoaming, small dot spacing, etc. Achieve the effect of low packaging equipment requirements, easy leveling and defoaming, and easy processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below with reference to specific embodiments. The following embodiments are not intended to limit the present invention, but are only used to illustrate the present invention. The experimental methods used in the following examples, unless otherwise specified, the experimental methods that do not specify specific conditions in the examples are usually in accordance with conventional conditions, and the materials, reagents, etc. used in the following examples, unless otherwise specified, are all Commercially available.

[0036] In specific embodiments, steps, material selections, and numerical parameters that are not described in detail are conventional selections in the prior art, or any prior art disclosed in the prior art.

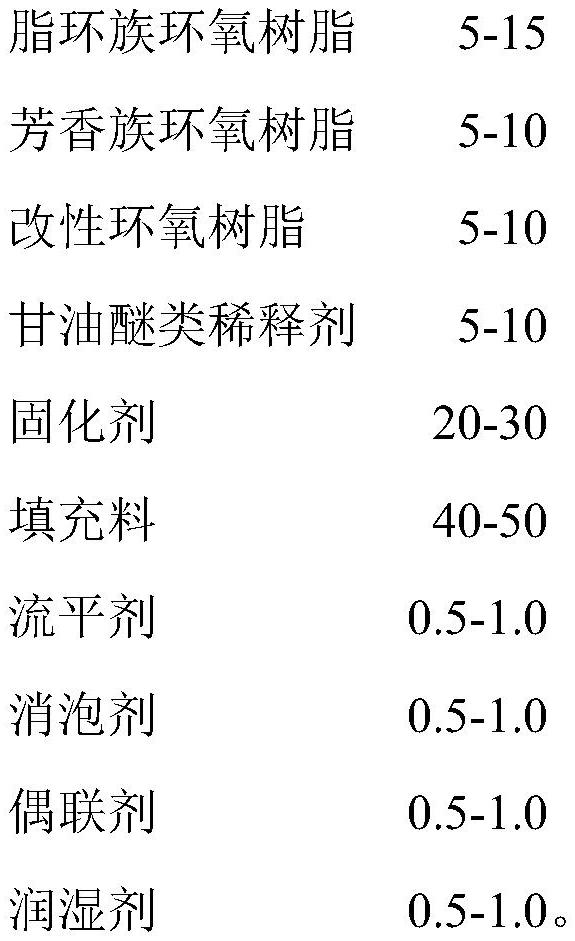

[0037] In the present invention, the specific grades of the substances used are shown in Table 1 below.

[0038] Table 1

[0039]

[0040]

[0041] In a specific embodiment, its pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com