LED epitaxial layer structure, LED epitaxial layer growing method and LED chip with LED epitaxial layer structure

A technology of LED chip and growth method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem that the brightness cannot be further improved, and achieve the effects of improving recombination efficiency, increasing overlap integral, and increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

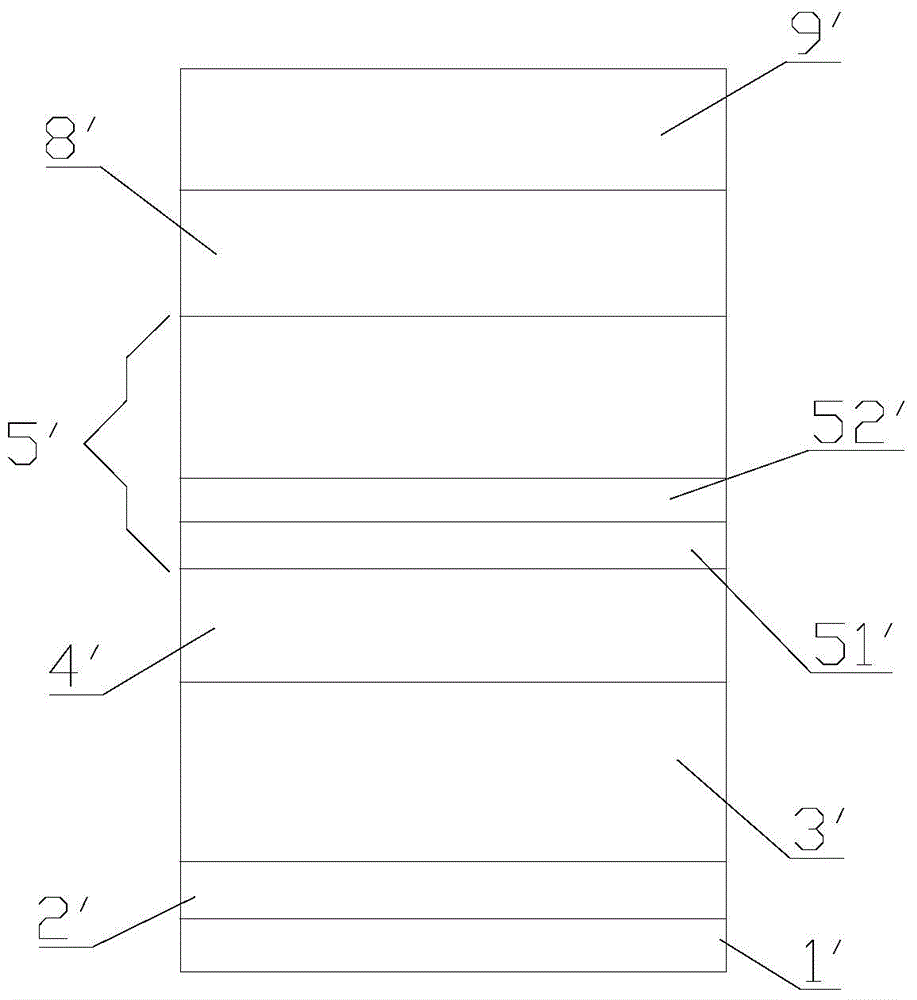

Embodiment 1

[0048] 1. Treat the sapphire substrate in a hydrogen atmosphere at 1000°C for 3 minutes;

[0049] 2. Cool down to 530°C and grow a GaN buffer layer with a thickness of 20nm on the sapphire substrate;

[0050] 3. Continue to grow 3um undoped GaN at a temperature of 1000°C;

[0051] 4. Then first grow 3μm N-type GaN continuously doped with Si, and the Si doping concentration is 1E+19;

[0052] 5. The light-emitting layer MQW is periodically grown, and the number of MQW unit cycles is 14, and the In in each cycle x Ga (1-x) The N layer is grown at 700°C and doped with In, with a thickness of 2.5nm. In the MQW unit x Ga (1-x) N (where x starts from the first In x Ga (1-x) 0.05 uniform gradient of N layer to 14th In x Ga (1-x) 0.3 of the N layer, the gradient rate is 0.017 / cycle) layer, the growth temperature of each GaN layer is 800°C, and the thickness is 11nm.

[0053] 6. Then raise the temperature to 900°C and continue to grow a 20nm P-type AlGaN layer with an Al dopi...

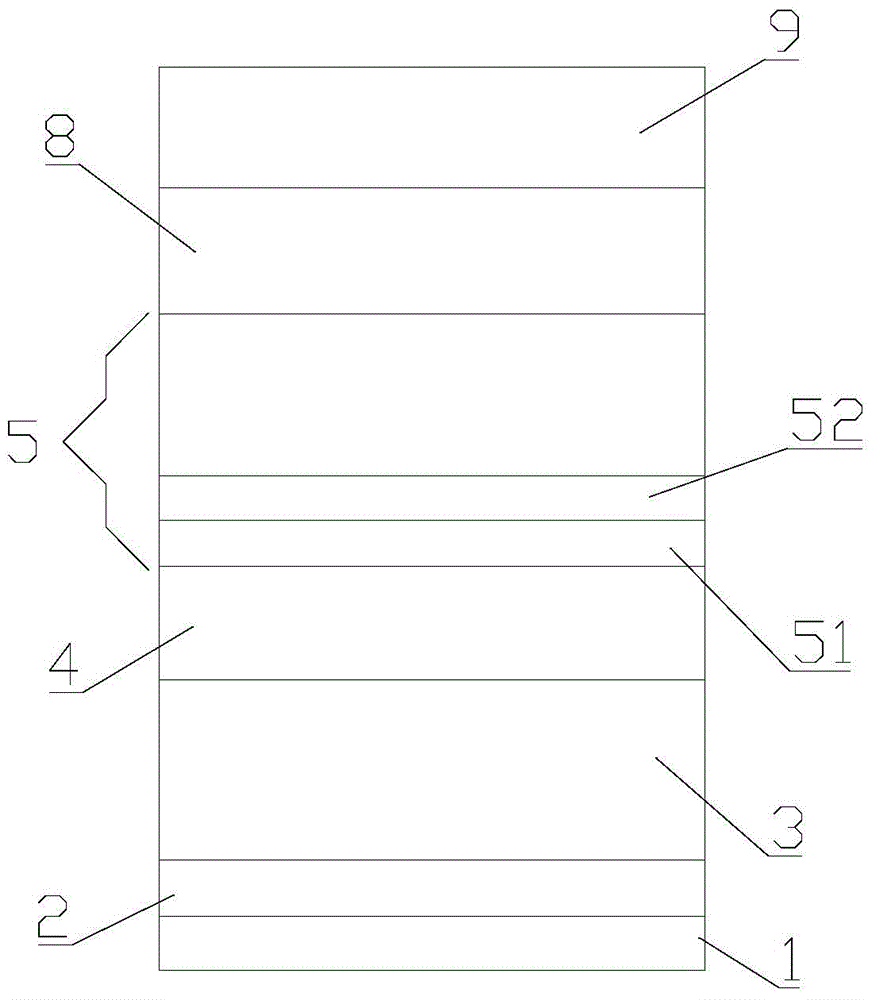

Embodiment 2

[0057] 1. Treat the sapphire substrate in a hydrogen atmosphere at 1200°C for 5 minutes;

[0058] 2. Cool down to 560°C and grow a buffer layer GaN with a thickness of 30nm on the sapphire substrate;

[0059] 3. Raise the temperature to 1100°C and continue to grow 4um undoped GaN;

[0060] 4. Then first grow 4μm N-type GaN continuously doped with Si, and the Si doping concentration is 2E+19;

[0061] 5. The light-emitting layer MQW is periodically grown, and the number of MQW unit periods is 16. Each In in the MQW unit x Ga (1-x) The N layers are all grown at 750°C doped with In, and each layer of In x Ga (1-x) The thickness of the N layer is 3 nm. In the MQW unit x is determined by the first In x Ga (1-x) The 0.30 uniform gradient of the N layer to the 16th In x Ga (1-x) 0.05 in the N layer, the gradual change rate is 0.017 / cycle), and the growth temperature of each GaN layer is 850°C, and the growth thickness is 12nm;

[0062] 6. Then raise the temperature to 930°...

Embodiment 3

[0066] 1. Treat the sapphire substrate in a hydrogen atmosphere at 1100°C for 4 minutes;

[0067] 2. Cool down to 550°C and grow a GaN buffer layer with a thickness of 25nm on the sapphire substrate;

[0068] 3. Raise the temperature to 1150°C and continue to grow 3.5um undoped GaN;

[0069] 4. Then first grow 3.5μm N-type GaN continuously doped with Si, and the Si doping concentration is 1.5E+19;

[0070] 5. The light-emitting layer MQW is periodically grown, and the number of MQW unit periods is 15. Each In in the MQW unit x Ga (1-x) The N layers are all grown at 740°C and doped with In. Each layer In x Ga (1-x) The thickness of the N layer is 2.5 nm. In the MQW unit x is determined by the first In x Ga (1-x) 0.1 uniform gradient of N to the 15th In x Ga (1-x) 0.3 in the N layer, the gradient rate is 0.013 / cycle) layer, the growth temperature of each GaN layer: 840°C, and the thickness is 11nm. ;

[0071] 6. Then raise the temperature to 920°C and continue to gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com