Dual ionic single fuel cell

A single battery and dual-ion technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve the problems of large drainage resistance, small pore size, and affecting battery performance, so as to improve battery performance and increase Effects on battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

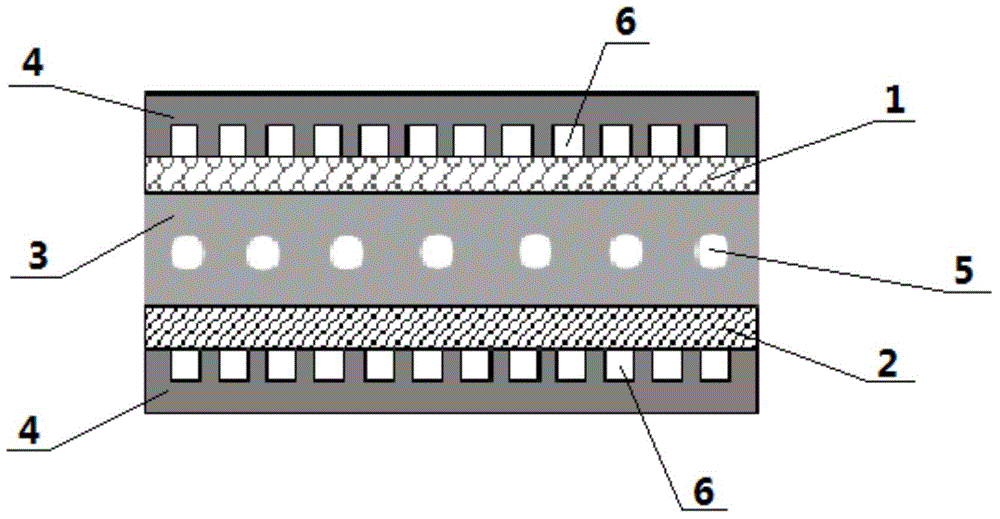

[0016] A dual-ion fuel cell with a flat structure, such as figure 1 As shown, it includes a positive plate 1, a solid electrolyte 3, and a negative plate 2 stacked in sequence. A current collector 4 is fixed on the outer contact surface of the positive plate 1 and the negative plate 2, and several conductors are provided on the current collector 4. The launder 6 is used for the passage of hydrogen or oxygen. The size of the positive plate 1 is 7cm×7cm×50μm, the material is NiO / BCZY, the size of the negative plate 2 is 7cm×7cm×20μm, and the material is BCZY / LSCF , The size of the solid electrolyte 3 is 7cm×7cm×10μm, the material is BCZY, which is a single-component electrolyte, and there are several parallel channels 5 in the same direction in the solid electrolyte 3. The direction of the channel 5 is the same as that of the solid electrolyte. The length direction of the channel 3 is parallel, the channel 5 is located in the middle of the solid electrolyte 3 and arranged in a str...

Embodiment 2

[0020] A dual-ion fuel cell whose structure is similar to that of Example 1. The difference is that the channel is located in the solid electrolyte near the negative electrode, and the cross-section of the channel is 2μm round shape.

Embodiment 3

[0022] A dual-ion fuel cell has a structure similar to the dual-ion fuel cell of Example 1, except that the cross section of the channel is a rectangle with four sides and a length of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com