Making method of steel casting mould of steam turbine

A technology of steam turbines and production methods, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., to achieve the effects of saving production costs, shortening production cycles, and utilizing storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A method for manufacturing a steel casting die for a steam turbine, characterized in that: the method comprises the following steps:

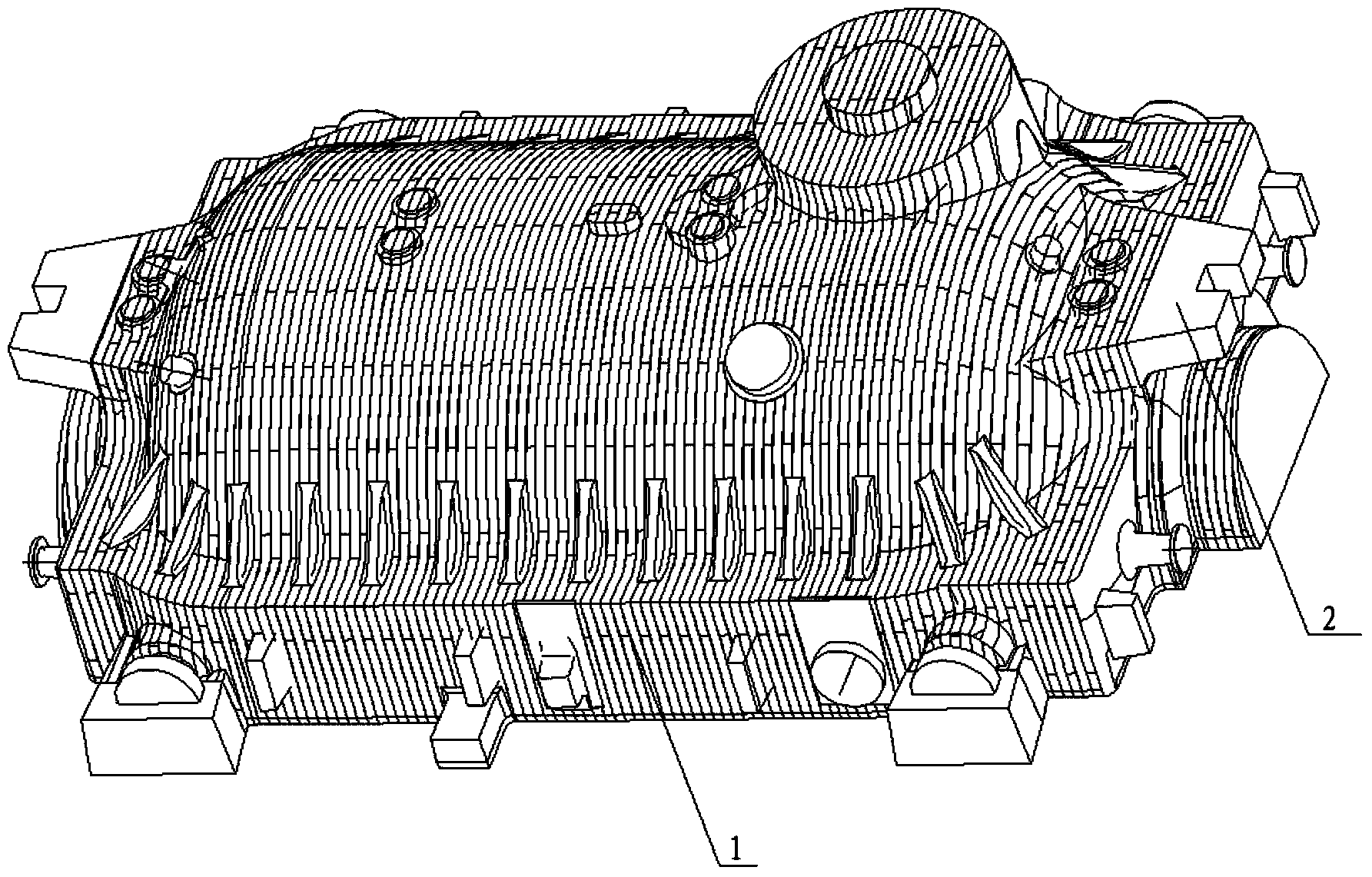

[0029] a. Establish the digital model of the steam turbine casting mold, such as figure 2 Take the digital model of the mold as an example, the outline size is 3339×2619×1444mm;

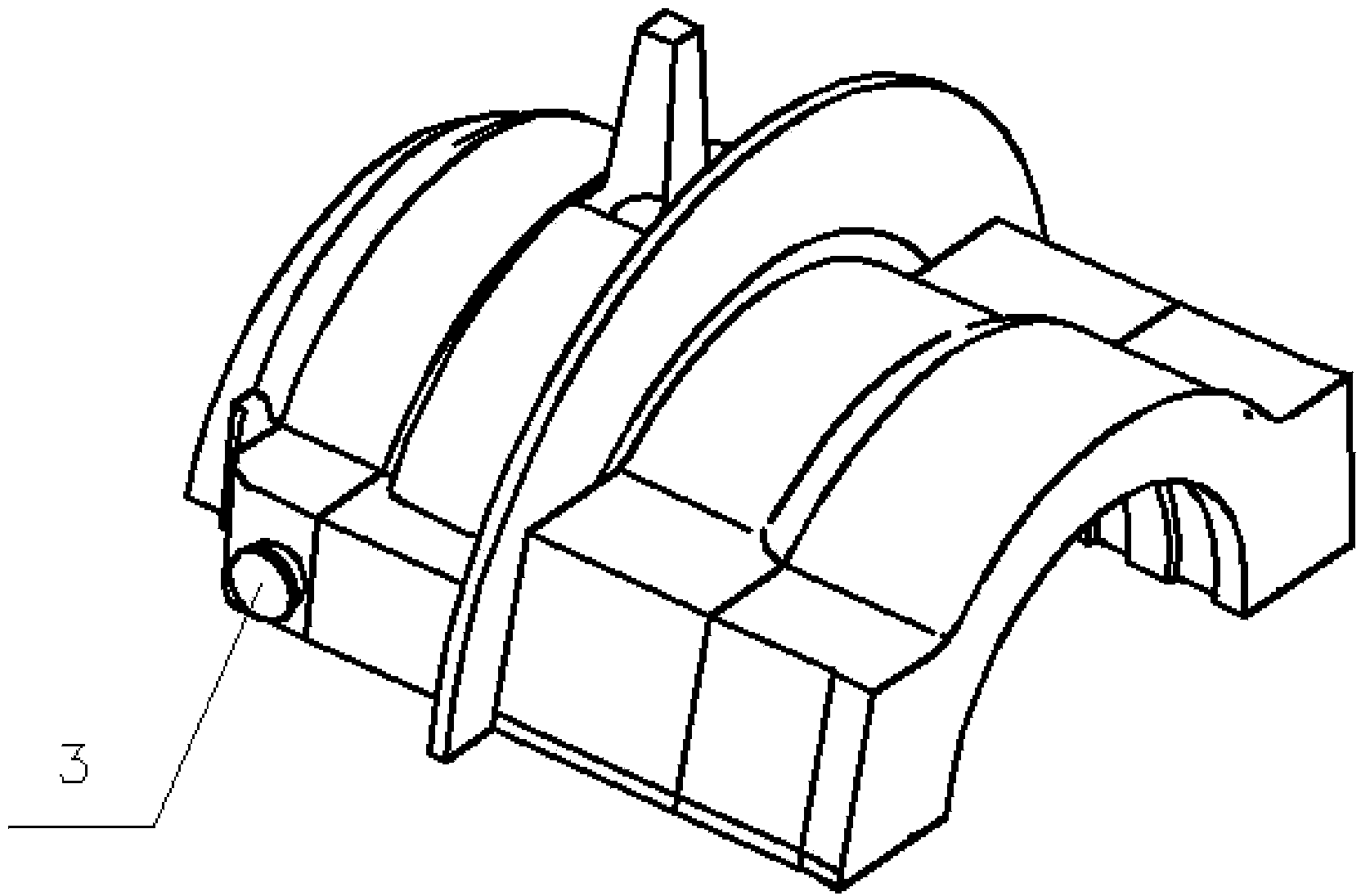

[0030] b. Such as image 3 Shown: Make the lugs, umbilicus and ribs on the digital model of the mold into loose blocks;

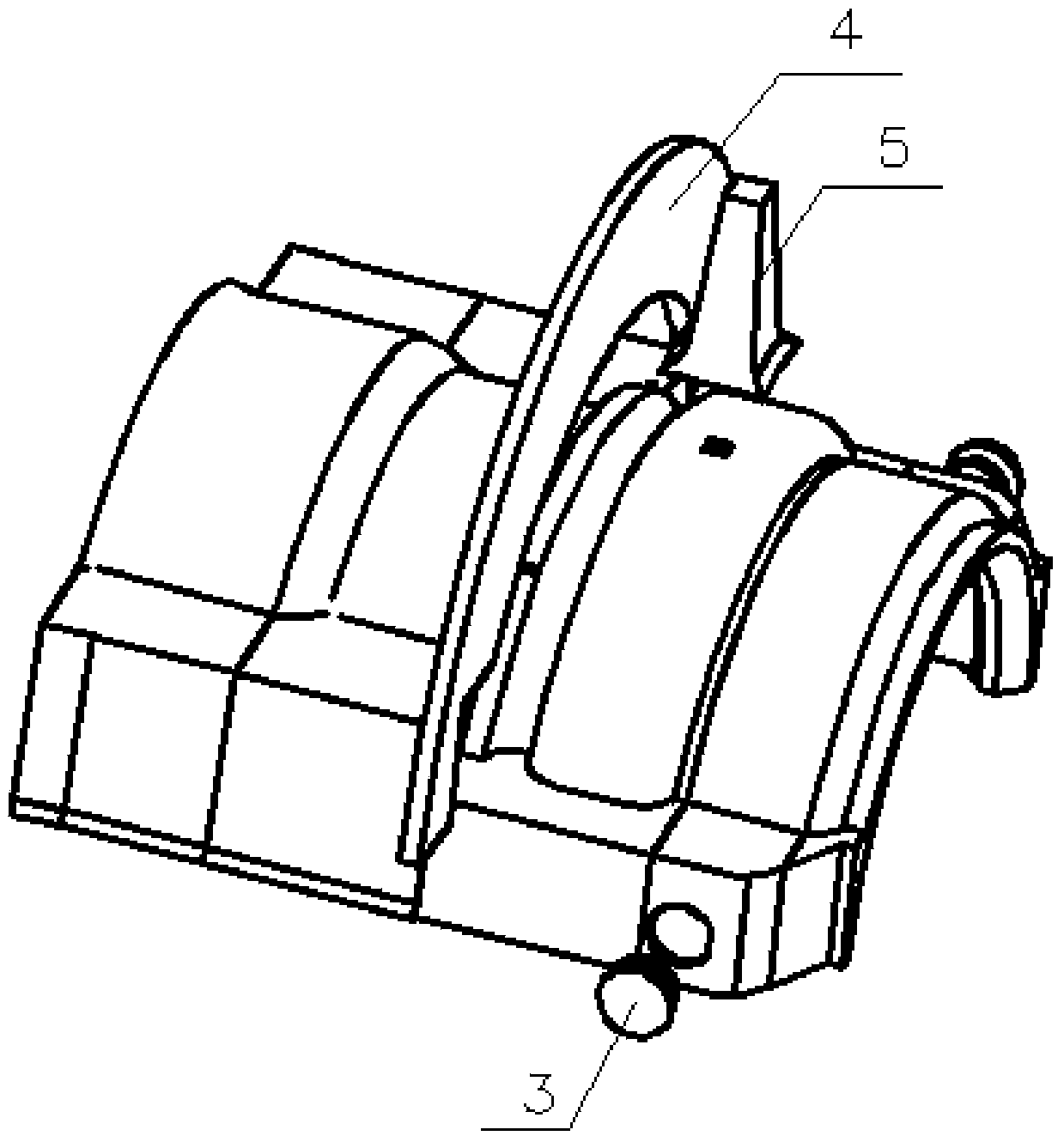

[0031] c. The main body of the mold depends on the structure and wall thickness of the main body of the mold, such as Figure 4 Shown: divided into 5 segments;

[0032] d. Assemble the five-section main body mould, and the loose part is determined to use the lost foam or wooden structure according to the number of times of use. Within 3 times of use, it is made of lost foam, and if it is used more than 3 times, it is made of wooden structure; between the loose block and the main body, the male and female buckles are used for position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com