Clamping jaw type metering device

A metering device and jaw technology, applied in the field of metering, can solve the problems of large energy consumption, large volume, high manufacturing cost, etc., and achieve the effects of improving metering accuracy, flexible and convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

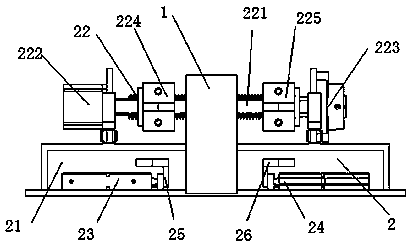

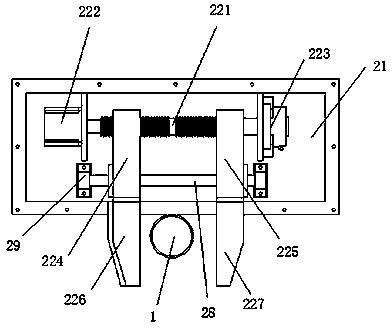

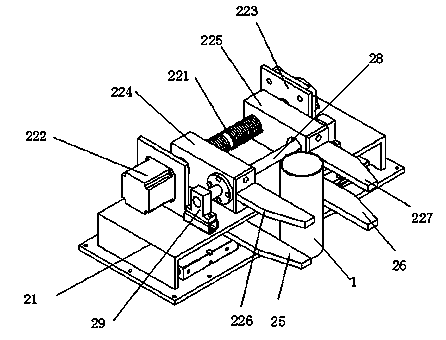

[0017] Such as figure 1 , 2 , 3, the claw-type metering device includes a feeding hose 1 and a clamping mechanism 2 for clamping the feeding hose 1; the clamping mechanism 2 includes a base 21 and a clamp arranged on the base 21 Fastener 22. Wherein the clamping member comprises a positive and negative screw rod 221; a motor 222 and a bearing mounting plate 223 respectively arranged at both ends of the positive and negative screw rod 221, wherein the motor 222 is fixedly connected with the positive and negative screw rod 221 through the motor mounting plate, and the bearing mounting plate 223 The outer side is fixed by nuts. A left slider 224 and a right slider 225 are symmetrically arranged on the positive and negative screw mandrel 221 between the motor 222 and the bearing mounting plate 223, and the left slider 224 and the right slider 225 can move forward and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com