Method for preparing graphene by peeling off graphite

A technology for exfoliating graphite and graphene, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve problems such as expensive, cost-increasing, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

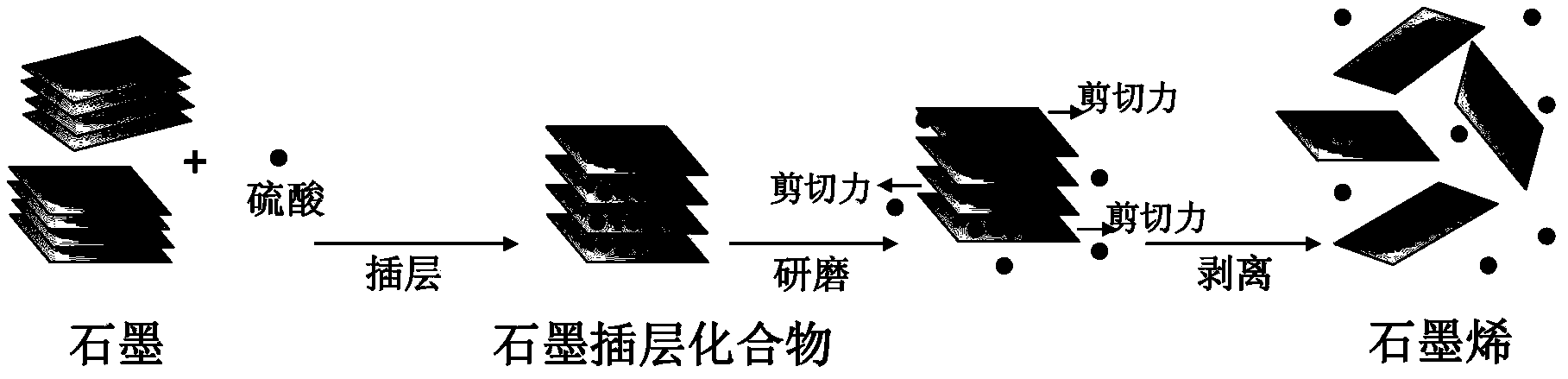

Method used

Image

Examples

Embodiment 1

[0027] Pour 0.5 grams of 50-mesh expanded graphite into a zirconia ball mill jar with a volume of 100 milliliters, then add 18 milliliters of 98.5% concentrated sulfuric acid, and finally add 100 diameters of 5 mm, 30 diameters of 7 mm, and 4 diameters of 10 mm zirconia grinding balls (the total weight of the three kinds of grinding balls is 81 grams), cover the ball grinding tank, and then seal the tank with PARA film. The above-mentioned sealed ball mill jar was placed on a planetary ball mill and ball milled at a speed of 500 rpm for 20 hours. Pour all the black mixture in the tank into 400 ml of deionized water, separate the balls inside to obtain a black slurry, add water and centrifuge until the pH of the product is greater than 6 (indicating that there is basically no residual acid), and finally dry, That is, a graphene powder product is obtained.

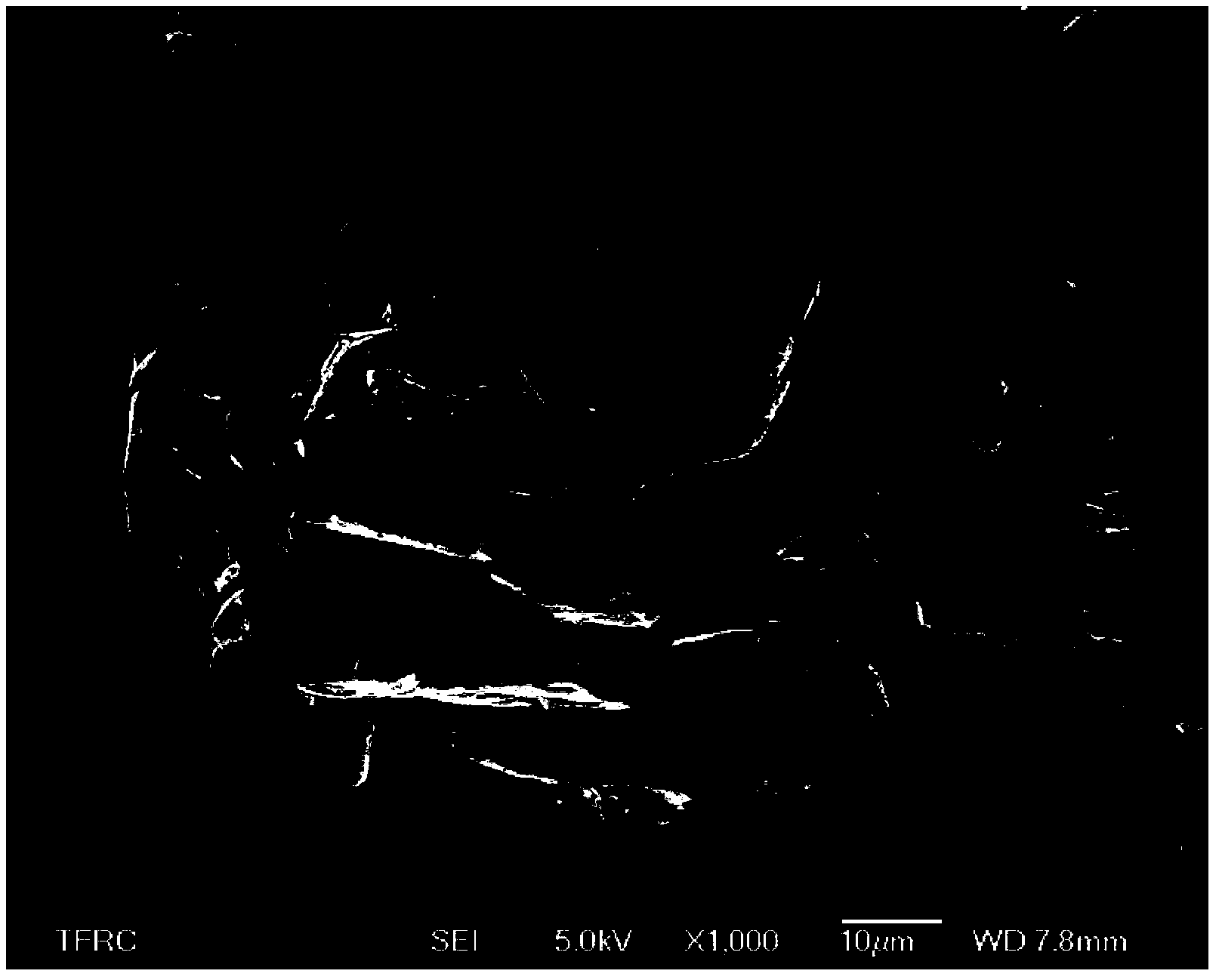

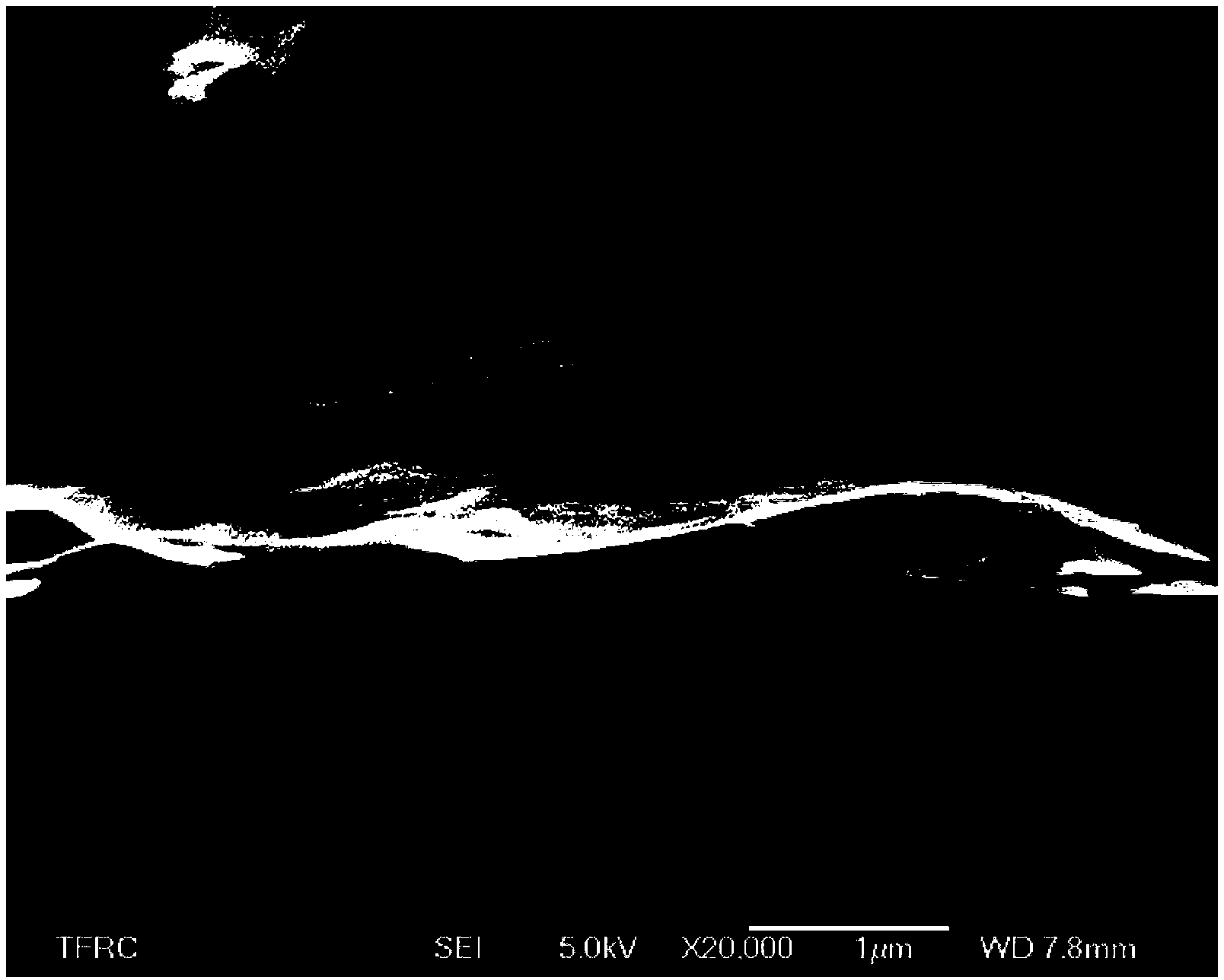

[0028] The scanning electron micrograph of the resulting graphene is shown in figure 2 with image 3 . from figure ...

Embodiment 2

[0030] Pour 0.5 grams of 325-mesh expanded graphite into a zirconia ball mill jar with a volume of 100 milliliters, then add 18 milliliters of 98.5% concentrated sulfuric acid, and finally add 100 diameters of 5 mm, 30 diameters of 7 mm, and 4 diameters of 10 mm zirconia grinding balls (the total weight of the three kinds of grinding balls is 81 grams), cover the ball grinding tank, and then seal the tank with PARA film. The above-mentioned sealed ball mill jar was placed on a planetary ball mill and ball milled at a speed of 500 rpm for 20 hours. Pour all the black mixture in the tank into 400 ml of deionized water, separate the grinding balls inside to obtain a black slurry, filter and wash by adding water until the pH value of the product is greater than 6 (indicating that there is basically no residual acid), and finally dry, That is, a graphene powder product is obtained. The powder resistivity and film resistivity of the obtained product are listed in Table 1.

Embodiment 3

[0032] Pour 0.5 grams of 325-mesh expanded graphite into a zirconia ball mill jar with a volume of 100 milliliters, then add 27.5 milliliters of 98.5% concentrated sulfuric acid, and finally add 120 diameters of 5 mm, 40 diameters of 7 mm, and 4 diameters of 10 mm zirconia grinding balls (the total weight of the three kinds of grinding balls is 100 grams), cover the ball grinding tank, and then seal the tank with PARA film. The above-mentioned sealed ball mill jar was placed on a planetary ball mill and ball milled at a speed of 500 rpm for 6 hours. Pour all the black mixture in the tank into 400 ml of deionized water, separate the balls inside to obtain a black slurry, add water and centrifuge until the pH of the product is greater than 6 (indicating that there is basically no residual acid), and finally dry, That is, a graphene powder product is obtained. The powder resistivity and film resistivity of the obtained product are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com