Aqueous strippable coating

A water-based and coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of affecting the appearance of the surface, the tape cannot cover every place, etc., and achieve the effect of good effect, wide applicability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

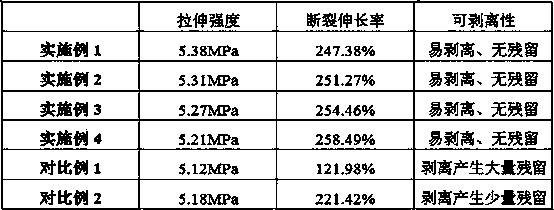

Examples

preparation example Construction

[0021] The preparation method of the present invention is a conventional method in the technical field, so it will not be described in detail here.

[0022] The embodiments of the present invention or the examples have no special instructions, the solid content of the water-based polyurethane emulsion used is 38-40%, the viscosity is 50-100mpa·s, and the elongation at break is 400-500%; the solid content of the water-based pure acrylate emulsion It is 46~50%, and the viscosity is 400~800mpa·s.

Embodiment 1

[0024] A kind of water-based strippable coating, according to weight percentage, is made up of following components:

[0025] Water-based polyurethane emulsion 42%; water-based pure acrylate emulsion 36%; release agent 6%; defoamer 0.5%; rust inhibitor 1%; leveling agent 0.5%;

Embodiment 2

[0027] A kind of water-based strippable coating, according to weight percentage, is made up of following components:

[0028] Water-based polyurethane emulsion 51%; water-based pure acrylate emulsion 31%; release agent 8%; water-based color paste 0.5%; rust inhibitor 0.6%; defoamer 0.5%; leveling agent 0.5%; .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com